Many wooden objects can be produced or repaired by gluing. Adhesive compounds are used for the manufacture and repair of furniture, musical instruments, carpentry.

- Wood glue selection criteria

- Types of adhesives for wood and joinery

- PVA

- Epoxy adhesive

- Bf

- Cyanoacrylate adhesive

- Heat resistant products

- Joiner adhesives

- The specifics of the preparation of wood glue

- Order of use

- Syndicone adhesive

- Glue paste

- Polyurethane compounds

- Casein glue

- Rating of the best wood glues

- PVA based glue

- Polyurethane adhesives

- Resin-based wood adhesives

- Professional wood glue

For a strong and durable connection, not inferior in strength to metal fastening, you need to choose high-quality glue for wood. To do this, take into account the operating conditions of the thing, the peculiarity of the material, the strength of the load and a number of other important factors.

to contents ↑Wood glue selection criteria

How to choose the best carpentry glue, which would be the most durable and ideal for a particular product? First you need to determine the type of tool. There are specialized compounds only for wooden substrates and universal adhesives, suitable at the same time for metal, PVC, ceramic tiles, rubber, glass, etc. Some products have an average degree of adhesion and can hold together parts of wood, plywood, chipboard together, while others are suitable for joining even dissimilar elements, such as wood and metal.

Despite the variety, experienced craftsmen prefer to apply narrowly targeted compositions that are ideally suited specifically to wood and its derivatives. But the characteristics of the tree in a particular case should also be considered when buying glue. Here are the main criteria that you should pay attention to:

- moisture, resinous wood;

- operation of the product in a normal or humid room, on the street;

- the need to withstand temperature extremes.

Some compounds help to connect only small products, the load on which does not exceed their own weight. Other items need to be fastened more firmly, as they are subject to physical or shock loads. Furniture or other glue for wood should be environmentally friendly, because the product will have to be used regularly by a person, and ventilation will not always be able to solve the problem of unpleasant odor or harmful fumes.

to contents ↑For the manufacture of cutting boards, countertops, it is worthwhile to use the so-called food glue - this product can come into contact with food without harm to the body. And, of course, when buying, it is worth considering the advice of professionals, expert opinion, the price of glue. Just how it turns out to choose a really worthwhile product.

Types of adhesives for wood and joinery

For woodwork, gluing and repairing products from particleboard, OSB, fiberboard and other materials, different glues can be used - PVA, polyurethane, casein, carpentry and many others. Before buying, it is important to determine the class of moisture resistance of the product, since only moist adhesive is suitable for wet rooms. All formulations are marked accordingly:

- D1. Designed for wood with a moisture content of up to 15%, can be used at temperatures up to +50 degrees.

- D 2.A short exposure to water on the seam obtained from such glue is allowed. You can work with it with wood moisture up to 18%.

- D3. The composition with this marking is moisture resistant, it is used indoors and for the repair of outdoor products. Short-term direct exposure to water is acceptable.

- D4. Products with the indicated marking are resistant to the destructive effect of aggressive factors, but to increase the useful life of the adhesive joint, it is still recommended to apply a professional protective composition.

PVA

Adhesive called PVA consists of polyvinyl acetate resins, it can be used for the repair and manufacture of tables, chairs, other furniture, panels, other products that are indoors. Some two-component PVA are suitable even for external use, as they easily withstand the action of moisture. The main types of funds:

- Standard PVA. It is an economical option, it is widely used for gluing small wooden products that are not exposed to moisture.

- Slow-setting PVA. The glue has a longer open exposure time, therefore it can be used for bonding large products.

- Thixotropic PVA. Designed specifically for vertical substrates, it is widely used in finishing work. The glue is thick, does not give smudges, drops, has high adhesion, hardens in 10 minutes.

- Water resistant PVA. It is allowed to use the product for outdoor products that periodically fall under the influence of rain, snow, but are not constantly wet. The tool is ideal for items in contact with food in the kitchen. The same glue is available in delayed setting and in dark color (for work on dark wood).

- Super water resistant PVA. Products fastened with a tool can even be immersed in water, the glue line will not collapse. Typically, compositions of this type are two-component and additionally include special hardeners.

to contents ↑Any PVA with rare use can exfoliate and precipitate in it. Shake the bottle just before use. It is desirable to remove stains of glue from the surface - they are opaque, therefore they will protrude under the varnish, stain.

Epoxy adhesive

Such adhesives consist of two components - resin, hardener. After mixing, the polymerization reaction begins, which leads to the formation of a durable, reliable weld that does not shrink. The more hardener added, the faster the reaction when applying glue to the surface, although the dilution ratios recommended by the manufacturer must be strictly observed. Spots of this glue appear under the stain, but are hidden by film coatings.

There are two forms of epoxy compounds:

- Standard glue. Before use, simply connect the resin and hardener. The tool perfectly fills gaps, cracks, suitable even for stairs that are experiencing severe stress. Epoxy glue is suitable for building and repairing ships, as it is moisture resistant. It is also used to connect dissimilar materials. The downside is the high cost.

- Five minute glue. This composition is quick-drying, it is usually used for bonding parts that are difficult to fix for a long time. The glue is suitable for joining oily and resinous wood, but has less strength than standard epoxy glue.

Bf

Under the brand name "BF" glues of different series are sold, and not every one is suitable for wood. Best for repairing wooden surfaces is the option marked 2 or 4 for indoor and outdoor use, respectively. The composition contains polyvinyl acetals, alcohols and phenol-formaldehyde resins. Here are the main characteristics of adhesives:

- quick drying (up to an hour);

- application in 2 layers after 15 minutes;

- maintaining temperature differences, freezing, heating up to +80 degrees;

- excellent moisture resistance;

- the need for thorough degreasing of the surface before gluing it.

to contents ↑After applying to the tree, a seam of amber or red color is formed, therefore glue bf Not suitable for every product. The disadvantage can also be called unsafe for health due to phenol-formaldehyde in the composition. Do not use BP for products in contact with food.

Cyanoacrylate adhesive

Such glue is often called “second” or “second”. Contact cyanoacrylate composition is familiar to everyone super gluesold in small packages. It is liquid, thick, medium density. More viscous compositions are recommended for filling gaps, liquid - for impregnation of small cracks.

How much does this remedy dry? The glue catches instantly, but is only suitable for temporary bonding or joining small parts. The finished seam on the wood will be brittle, it can be destroyed by a strong blow, so superglue often fixes the details for a more convenient application of a different composition.

to contents ↑Heat resistant products

Usually hot glues sold in the form of glue sticks, which are melted in a special gun and are used to connect chipboard, MDF. Whole wood is not bonded with such adhesives. Despite the name, the product cannot be considered heat-resistant: with strong heating, the glue line melts again. Therefore, they most often close up small defects or attach fabric, foam to furniture. As a truly heat-resistant agents, standard epoxy adhesives are used.

to contents ↑Joiner adhesives

By carpentry adhesives is meant a whole group of products based on bone and fish meal, as well as mezdra, so they are considered natural. Most often, fish glue is used, which is made from the remains of fins, fish bubbles. Due to the high price, it is used mainly for the restoration of wooden products, antique furniture, tools.

The glue is made from the remains of leather raw materials. Its basis is a dry protein produced from the skin. Bone glue is created from cysteine, collagen, gelatin obtained from animal raw materials. Joiner glue is sold in two forms:

- traditional - powder, granules that must be diluted with hot water;

- adapted liquid composition.

The specifics of the preparation of wood glue

The traditional composition before use must be properly prepared, it is not difficult to do it yourself. The dry mass is poured with warm water according to the proportions recommended by the manufacturer, it is kept for 6-12 hours to completely impregnate the powder. After putting the product in a water bath, prepare until all solid particles are dissolved, avoiding boiling.

to contents ↑Order of use

The parts to be glued are carefully coated with wood glue, moving in the direction of the wood fibers. The layer of the product should be uniform. Further, the products are tightly pressed against each other, fixed for 7-8 hours. The glue is not used when wood moisture is more than 10%, its adhesion is seriously reduced.

Syndicone adhesive

In practice, such a tool is used infrequently, since it is a home-made glue that is not sold in stores. You can do it at home like this:

- dissolve 10 parts sugar in 30 parts water (distilled);

- introduce 2.6 parts slaked lime into the syrup;

- warm the mixture in a water bath for 3 hours, avoiding boiling;

- combine the resulting solution equally with the powder of wood glue, heat under the lid for 5 hours;

- For storage, drip a little vinegar into the finished composition.

to contents ↑The tool can be used in a day - so much time it needs for insisting. Synthetic adhesive is resistant to chemicals, physical influences, provides greater adhesion.

Glue paste

The composition of the adhesive includes various components, which in themselves are separate adhesive compositions. A distinctive feature is the enhanced adhesion and viscosity of the paste - it is similar to a putty mixture. Glue pastes connect products from non-planed boards, since the product protects them from moisture due to reliable clogging of pores.

Polyurethane compounds

Conventional liquid polyurethane adhesive is suitable for use even with oily and damp wood, since it hardens upon contact with moisture. Dry products must be moistened before bonding. The glue is particularly suitable for antiseptic-coated wooden structures. In appearance, it resembles a mounting foam - it is also extruded, hardens. In addition to gluing wood to wood, a polyurethane compound will help connect wood with dissimilar materials:

- metal;

- ceramics;

- glass;

- plastic.

The main composition of the glue is represented by synthetic resins, because it is durable, waterproof, heat-resistant. Special tinted adhesives are on sale, they usually have a light brown tint and are invisible on wood. There are also polyurethane hot melt adhesives, their purpose is as follows:

- fastening parts from wood without fixing;

- connection of loosely fitted products with small gaps;

- gluing oily wood.

The difference between the melts is in an even higher level of adhesion with different hard-to-stick materials in 0.5-1 minutes, therefore, fixing parts is not required. But before the moment of operation, more time should pass than with conventional glue - up to 24 hours. This helps the adhesive joint to achieve final strength. To apply the melt, an additional glue gun is required.

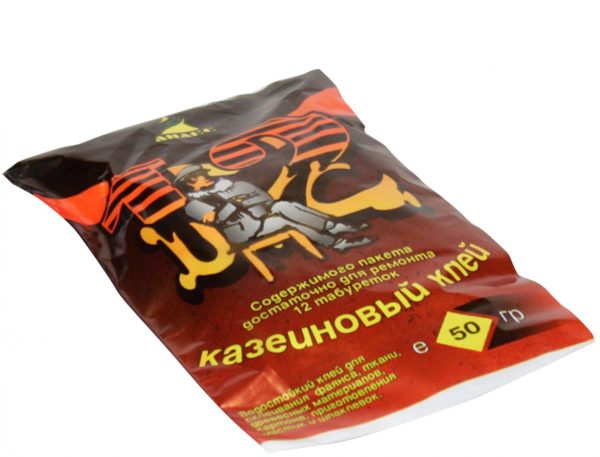

to contents ↑Casein glue

The main substance in the composition is milk protein, because the product is environmentally friendly, safe for humans. In implementation casein glue presented in packages with dry granules of light yellow color. The downside is the shrinkage of the glue after drying, the color change of the glued surfaces. Without antiseptic, casein glue is prone to mold.

to contents ↑Rating of the best wood glues

Professionals prefer to buy adhesives of famous brands: "Titan", Titbond (Titebond), “Moment”, etc. In different categories there are leaders who beat records for purchasing power.

PVA based glue

This group of adhesives is the most popular, it includes a huge number of items of domestic and foreign manufacturers. Here are some examples:

- Kleiberit 303.0. The German tool, has high water resistance, allows you to connect parts from all types of wood, veneer, fiberboard and particleboard. It requires a short fixation time of products - only 6-10 minutes. The glue is resistant to low temperatures, has a white color. Advantages - ease of use, resistance to the influence of atmospheric factors, water. The disadvantage is a higher price.

- “Moment Carpenter Instant Grip”. It is a universal tool based on acrylic dispersion, which can not only glue wood qualitatively, but also fill cracks and defects up to 5 mm deep. It is solvent free, ideal for all types of wood. Advantages - transparency after drying, convenient application, quick drying, high initial adhesion. Minus - unsuitability for some types of plastic, Teflon, poor resistance to moisture.

- Ultima Joiner PVA. The tool is notable for the high strength of the seam, they can glue even those products that are subjected to dynamic loads. The glue does not break down from low temperatures (up to -35 degrees), withstands 4 cycles of freezing / thawing. Pros - versatility, frost resistance, seam strength. Minus - long drying.

Polyurethane adhesives

Such products belong to the professional line of wood adhesives; they are most often used in furniture production. Examples of quality formulations:

- "PUR-adhesive 501." Waterproof glue of category D4, used for gluing wood, windows and doors, building materials.This reactive adhesive cures from moisture, withstands high loads, and is heat-resistant. Advantages - simple application, high pot life, short cure time, ductility. Minus - high price, brown color.

- Titebond Polyurethane Wood Glue. The glue retains its working properties for 20 minutes, perfectly combines any wood products and wood-based materials. Not afraid of frost, it only needs to be warmed to room temperature before use. Pros - suitability for different materials, the highest degree of adhesion. Less - hard to find, high price.

- Soudal 66A. It is used to connect wood with any other materials except polypropylene. Differs in high moisture resistance, can even glue wet products. Due to foaming, it penetrates into small cracks, reliably fills all defects. Advantages - large temperature range of application, high adhesion, disadvantages - strong expansion after drying.

Resin-based wood adhesives

The products contain epoxy or polyester resin, as well as a number of other synthetic components. Here are the best in the ranking:

- UHU PLUS ENDFEST 300. The strongest epoxy composition, its setting time is 1.5 hours, the time of complete curing of the seam is 12 hours. Advantages - impact strength, water resistance, durability of the seam. Cons - the need for strict proportions.

- EAF. An epoxy compound at an attractive price that allows you to make furniture and repair it. Differs in high adhesion, water resistance. Pros - the possibility of introducing fillers, availability, cost-effectiveness, lack of shrinkage. Cons - the inability to use for products in contact with food, long drying.

Professional wood glue

Of the variety of carpentry adhesives, professionals distinguish the tool "Taytbond 3 Ultimate." It is one-component, waterproof, while its spots are cleaned with water. The material has a high initial setting. A dry joint can even be sanded without the risk of structural damage. Glue does not harm humans, can be used for products in contact with food, suitable for indoor and outdoor use. Disadvantages of the drug were not found.

Choosing high-quality glue, you can be sure of the strength of the connection of parts and the long service life of wooden products, so when buying it is better to stay on the product of proven brands!