After superglue was invented, the repair process of many household products was greatly simplified. To apply such formulations is simple, they instantly dry and fasten the parts tightly. Superglues are ideal for most popular materials, do not corrode them and do not cause deformation.

- The history of the invention of glue

- Features of the composition of superglue

- Properties and specifications of superglue

- Areas of application of superglue

- How to work with cyanoacrylate superglue - procedure

- Superglue Solubility and Safety

- Adhesive Manufacturers

- Tips & Tricks

The history of the invention of glue

Superglue began its history in 1942. It was at this time that the American chemist G. Coover, when conducting experiments with cyanoacrylate, received a new substance with unique adhesive abilities. Initially, the scientist did not have a goal to create glue, he worked on improving transparent plastic for optics, working for Kodak. Therefore, superglue, as a by-product, was ignored for some time.

They recalled the cyanoacrylate composition after 9 years when searching for universal glue with waterproof and heat-resistant properties for aircraft construction. At that time, it turned out to be too sticky and deteriorated, even if it came into contact with moisture a little. After extensive work, Harry Coover and colleagues improved the composition and received a quality base for glue.

Even 7 years later, in 1958, superglue appeared on the market under the Eastman 910 brand. But he did not become popular immediately, but only after the release of a television program about its properties. The inventor greased the cable and the metal rod with superglue, connected them, and after drying, hung on the structure in the air - the strength of the composition was enough to support the weight of a person. After the patent for the production of superglue was given to National Starch, and later many brands began to produce it.

to contents ↑Features of the composition of superglue

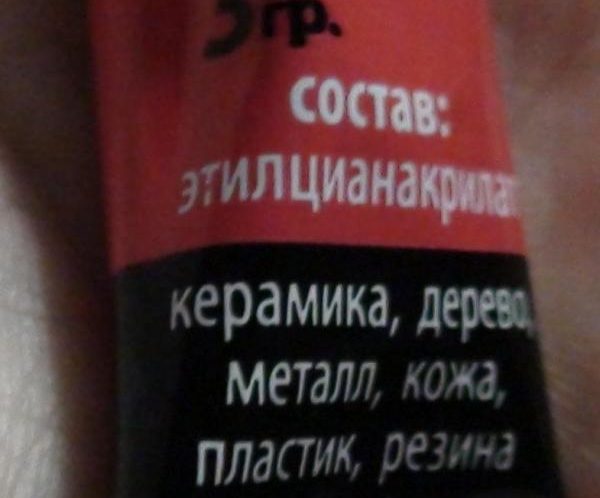

The molecular formula is the same for all cyanoacrylate adhesives: CH2 = C (CN) COOR. This is a liquid monomer of cyanoacrylates, or an ester of cyanoacrylic acid. R is a radical, it can be ethyl, methyl, butyl and other monovalent radicals, depending on which the technical characteristics of the adhesive change. In any superglue, up to 97-99% cyanoacrylate is present, as well as the following substances:

- plasticizers - give superglue elasticity;

- stabilizers - keep the glue quite liquid before application and provide the necessary properties after solidification;

- thickeners - provide the necessary density and consistency of the gel;

- modifiers - necessary to enhance the water resistance of superglue to the level of D3-D4, heat resistance (divinylbenzene, cyclopentadiene and others);

- adhesion promoters - increase adhesive strength (PVA, polyacryl);

- curing activators (needed with insufficient moisture) or curing inhibitors (to prevent spontaneous polymerization);

- fine metal powders - to improve the conductivity of electricity.

Unlike other adhesives, superglues do not contain organic solvents. This makes them safer for humans, as well as suitable for bonding metal. On sale you can find different names of superglue, which are supplied in the form of blisters, tubes, jars, adhesive tapes. They have one thing in common: a small amount of packaging, because after opening it, even with a slight decrease in tightness, the adhesive from the gel quickly becomes viscous, and then completely deteriorates.

to contents ↑Properties and specifications of superglue

Superglue is often called "second glue", its feature is a very quick solidification in the air, on the fingers. How much does superglue dry? Usually, the composition hardens in 5-60 seconds, but it takes 6-24 hours to fully cure and start operation. At low humidity, curing of superglue can take up to a couple of minutes, but when it comes in contact with water and high humidity, it occurs almost instantly.

Other properties and characteristics of the product:

- the glue holds the parts firmly even when applying a thin layer, the main thing is to firmly press the bases;

- Superglue seam tolerates high loads - up to 150-250 kg / sq. cm;

- dried superglue is a translucent, medium elastic mass;

- most superglue can withstand temperatures in the range of -60 ... + 80 degrees, very frost-resistant, do not respond to gasoline, oils, alcohol;

- some compounds not only work well in cold weather, but are also heat-resistant, do not deteriorate at temperatures up to +250 degrees;

- superglues without the introduction of special additives weakly conduct current and can serve as insulating compounds;

- it is possible to apply means in the presence of gaps up to 0.1 mm, although some superglue has an increased viscosity, therefore they can close gaps up to 0.25 mm (larger gaps should be filled with an epoxy or polyurethane compound);

- the consumption of superglue is very low - a drop can cover a circle with a diameter of 2.5 cm;

- most formulations are single-component, but two-component super-adhesives are also on sale.

Adhesive products are characterized by high adhesion to many materials, including when connecting dissimilar surfaces. They are suitable for plastic, glass, wood, metal, rubber, ceramics. Superglues can be applied on vertical, horizontal, inclined products. They are not suitable only for Teflon, silicone, polyethylene, and it is also forbidden to stick together dishes that come into contact with food.

to contents ↑It is better to prevent contact of the adhesive joint with acetone, dimethyl sulfoxide, isopropanol, since superglue is unstable to these substances. The fracture joint strength will not be too large, as the elasticity of the composition is average.

Areas of application of superglue

Usually glues based on cyanoacrylate are used where it is necessary to quickly glue and quickly dry products, for example, when installing windows to fix seals, when attaching radio components, instrument assemblies, optics, microcircuits. In everyday life, many radio amateurs use their own glue based on superglue and soda: when mixing the components, the mixture instantly turns into a solid “plastic” and firmly connects the wires and parts. The same mixture can be used to repair cracks, chips, pits.

The areas of use of superglue are diverse:

- repair of shoes, leather goods;

- manufacturing of constructions in dentistry, orthopedics;

- creation of jewelry;

- advertising production;

- construction;

- sewer plumbing;

- bonding of rubber products;

- instrument making;

- sealing of different nodes;

- cold welding of polymers, elastomers.

There is even medical superglue - an analogue of BF-6. They use it for sealing wounds, quickly stopping bleeding, and impregnating dressings. Some superglues, when applied to paper, cardboard, and other compositions containing cellulose, enter into an exothermic reaction. Therefore, on these surfaces, you first need to try superglue on an inconspicuous area and only then apply it to work.

to contents ↑How to work with cyanoacrylate superglue - procedure

Any gluing of objects with superglue can be done at home, for this you do not need to have special skills.The instructions for working with it are simple, it is important to perform all actions quickly - there will be almost no time to adjust the position of the parts. Only on soft, hygroscopic materials is gluing with superglue slower, and it will be possible to correct their location within 30-120 seconds.

Prior to bonding, large gaps and cracks need to be filled with concrete dust, dry plaster or soda, and then super-glue is added there - defects will immediately be filled with a dense white acryl-like mass. The surface should be washed, remove all dirt, grease. Acetone or alcohol can be used as a cleaner and fat remover. Further, the procedure for working with superglue is as follows:

- pierce the metal protection on the tube with the top of the cap;

- apply a little superglue to a completely dry base, firmly press the second part;

- start gluing from the center to the edges, otherwise air may get into the seam;

- press parts for 10-30 seconds;

- leave the product to dry.

to contents ↑At the end of the work, you need to wipe the tube nose from the superglue, tighten it tightly. To open, if the cap is stuck, the bottle will be problematic, so you need to clean it carefully.

Superglue Solubility and Safety

If the superglue has thickened, it will not work to dilute it. In any case, upon contact with air, it instantly hardens. If glue gets on unsuitable surfaces and materials, it is also difficult to dilute it, there is a risk of damage to the base. As a means to remove superglue, you can use acetone, another organic solvent, but it is not always possible to clean the product. You can purchase a specialized wash, the best is considered to be the best Kosmofen. Replace the wash with nitromethane.

When working with superglue, do not wear cotton gloves. When soaked, there is a risk of an exothermic reaction with a burn. It is better to use ordinary rubber gloves. The room should be carefully ventilated: despite its low toxicity, many superglue emit an unpleasant odor. In case of contact with eyes, rinse well with clean water and consult a doctor immediately!

to contents ↑Adhesive Manufacturers

Superglue is produced by almost all well-known manufacturers of similar products, both foreign and domestic. Here are the most popular brands:

- "Contact". Superglue plus primer. The tool is sold complete with a primer, designed for fastening complex and heterogeneous materials, including plastics ABS, PP, PE. The primer increases the surface activity of materials, which increases the adhesion of superglue. The basic composition is applied to the surface after complete evaporation of the primer.

- “Super Epoxy Moment”. This superglue is two-component and does not include cyanoacrylate, instead of it there is an epoxy resin in the composition. Both components (resin and hardener) are placed in convenient syringes, from which they can be squeezed out strictly dosed. Super Moment glue is ideal for gluing porcelain, crystal, wood, clay products, plastic, metal, precious stones.

- "Super grab." Another epoxy two-component superglue suitable for metals and alloys, glass and ceramics, decorative and cladding panels. It can be used for industrial purposes. Superglue does not shrink, low toxicity, its use as a putty, sealant is allowed.

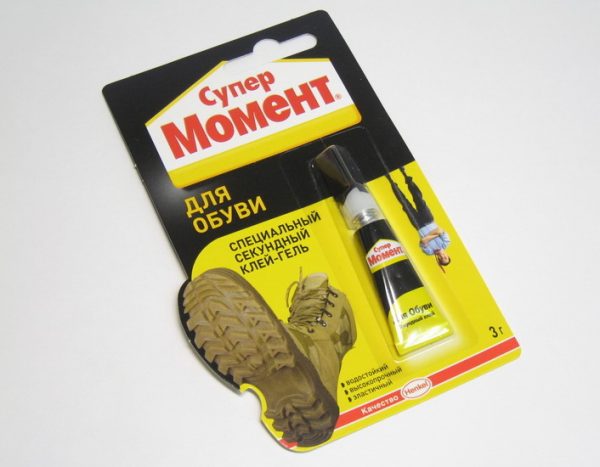

- "Monolith". This is one of the cheapest superglue, with decent quality. Most often, the composition is used to repair shoes, gluing heels, soles. Superglue reliably holds together leather, leatherette, vinyl, plastic and metal, wood and all its derivatives.

- "Superglue 505 Universal heavy-duty." The tool hardens in 20 seconds, completely transparent, suitable for all materials except Teflon, styrofoam, polypropylene and polyethylene. The disadvantage of superglue is the stiffness of the adhesive joint, which poorly withstands fracture loads. A variety of tools is "Superglue 502", characterized by higher heat resistance.

- "Master". This superglue holds together ceramics, porcelain, plastic, metal, leather, rubber, cardboard and wood.It is sold in mini-packages of 3 g, as well as whole blisters, in which there are 12 tubes / 3 g.

- Crox 301 Universal superglue for any materials, provides reliable fastening for a long time. Seals, fills cracks and chips. It has a very convenient applicator, protected from solidification of the composition in the channel.

- Super Moment Pro. Reliable, durable superglue, packed in a reusable bottle with a convenient lid. Moisture-resistant, heat-resistant, suitable for all materials except very soft leather, polyethylene, polypropylene, Teflon, silicone rubber. Also, superglue of this brand is not used on glazed surfaces.

- Loctite. The fast polymerizable cyanoacrylate-based composition has a low viscosity. Superglue is designed for any materials, especially those that are difficult to glue. Its stability is less dependent on air humidity than other glues. The downside is the high price.

- 5 Second Fix. Other names of glue - plastic welding, liquid plastic retainer. It has an original design in the form of a pen with a thin tip, which is equipped with a battery and an ultraviolet emitter. After applying the product, you need to shine on it for about 5 seconds, which seriously increases the strength of the glue line.

- Wurth Klebfix. Structural adhesive for installation and repair, conveniently opens and closes, is equipped with a system to prevent spillage. The bottle has a dispenser, and the glue is applied strictly drop by drop. The bonding quality of this composition is at the highest level.

Tips & Tricks

In the original packaging, the products are stored for 6-12 months, depending on the particular brand. Cheap superglue usually hardens quickly after the first use, and it makes no sense to store the tube started. To extend the shelf life, you can put a tightly closed bottle in the refrigerator.

It happens that superglue gets on the skin, and removing stains can be quite difficult. Such a phenomenon does not present any danger, therefore, you can calmly wash your hands several times with warm water and soap. If you need to cleanse your skin urgently, you should use Dimexide, diluted with water, soda solution, alcohol, vegetable oil, twice diluted with water. Superglues are inexpensive and reliable helpers in the house, with their help you can repair any product in a short time without special time and financial costs!