Casein glue can be used to glue plastic, ceramic, wood, foam and many other materials. This tool is unique - it contains only natural ingredients, is completely harmless to humans, while it is prepared in industry or with your own hands - at home.

- Composition and properties of glue

- The purpose of the funds

- Use in icon painting

- Casein and its manufacturers

- DIY glue making

- Industrial glue production

- Pros and cons of glue

Composition and properties of glue

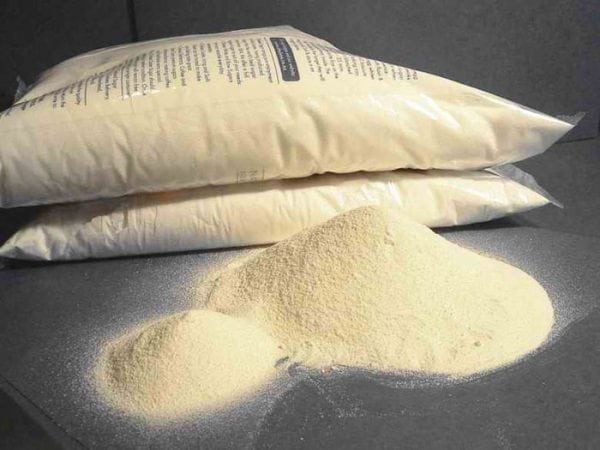

In appearance, casein is a grayish powder with small and larger granules. What is it, what does this tool consist of? By chemical composition, casein is a milk protein, it contains many essential amino acids, calcium caseinate, phosphates, nitrates. Casein-based glue may have a different composition depending on the brand and subsequent use. Most often it is used for wood, and the adhesive composition includes such additives:

- lime;

- rosin;

- kerosene;

- water

- sodium bicarbonate, etc.

The consistency resembles a paste. All the components included in it are environmentally friendly, therefore the furniture, for gluing of which the agent was used, is produced with the mark “ECO”.

Technical characteristics and properties of dry material are as follows:

- types of glue - “ordinary”, “extra”;

- appearance - gray powder, which does not have foreign inclusions, a small amount of lumps is permissible (break up when rubbing with hands);

- smell - specific, not putrid;

- solubility in water - good, no residue;

- dynamic viscosity at room temperature - 10.8-27 P;

- preservation of fluidity after dilution: for "extras" - 5 hours, for "ordinary" - 4 hours;

- bonding strength of wood during dry testing - for "extras" - 105 kgf / sq. cm, for the "ordinary" - 75 kgf / sq. cm.

The purpose of the funds

The main area of application of glue is the manufacture of furniture, other wood products, so it is often called carpentry. In the furniture industry they use it everywhere, it helps to cover the frames with leather, leather substitute, plastic, perfectly glues wooden parts. A feature of the material is improved wood structure and environmental friendliness.

Casein glue is also in demand in construction - it is included in the composition of putties, putties, enamels of many grades and is actively used in finishing work. To enhance the durability of facade paints, glue is also added to them - the coating will last longer. Glue labels on dishes, glass products. In addition, the material will help fasten together products from:

- cardboard;

- tissues;

- faience;

- polystyrene foam;

- polystyrene foam;

- plywood.

Casein itself is a valuable raw material for the chemical industry, it is used to prepare plastic and ceramics, while casein glue easily glues these materials.

to contents ↑Casein powder is also used in printing houses, painting, production of pigments, toys, in the food industry. It can even be used as an additive in infant formula to enhance the nutritional properties of the latter.

Use in icon painting

The composition of the adhesive includes proteins, among the chemical components of which are nitrogen and sulfur. This allows the material to provide antifungal and antiseptic properties - the products processed by it do not decay.Such features of glue determine its popularity in icon painting techniques. For this area, the finished glue may include other components, here are the main ones:

- borax;

- caustic lime;

- caustic potassium, sodium hydroxide;

- ammonium carbonate;

- ammonia.

All of these solvents are alkaline in nature and help to create an adhesive that has high adhesion and excellent adhesive properties. Also, the resulting product can emulsify oils, varnishes. The addition of alkali prevents cracking of the material after complete drying. To create a particularly strong coating, acetic alumina, formalin are added to the glue.

to contents ↑Casein and its manufacturers

Casein is obtained by curdling milk from its predecessor, caseinogen. This substance can be called part of the complex structure of milk, where it is in the form of calcium caseinate. Casein coagulation process is familiar to many - when lactic acid bacteria enzymes get into milk, cottage cheese is formed. In industry, technical casein is obtained to create glue by adding acid to milk.

Technical casein is available in four grades:

- Top grade. It is represented by the same small (up to 5 mm) granules of a white, cream shade, does not even have the slightest inclusions.

- First grade. The color is a little yellowish, the grains are the same in size, with some sticking allowed.

- Second grade. Yellow powder from grains up to 10 mm in size, the presence of lumps is acceptable.

- Third grade. The color of the powder is dark yellow, brown inclusions are possible.

To obtain glue at the factory, raw materials are purchased from dairy plants. The greatest demand is the products of Western countries. In Europe and America, a number of modern technologies are used that make it possible to produce casein of the highest quality at no extra cost (ejector method, by coagulating casein and other methods).

to contents ↑DIY glue making

There are a number of ways to make good casein glue at home. In the future, they can stick any of the above materials. What do they make the product themselves? Here is the easiest cold method based on cottage cheese:

- take 40 g of store curd;

- grind the cottage cheese through a sieve to get a fine powder;

- add 10 ml of ammonia to the mass;

- mix well, the product is ready.

You can go the hard way and make glue from milk. To do this, a liter of milk is heated without boiling, 9 teaspoons of vinegar essence are introduced into it. The mass is heated until lumps of cottage cheese appear. It is filtered through cheesecloth, spread in a pan, add 3 tablespoons of soda, a few drops of water. Warm until mass begins to bubble, then mix thoroughly and allow to cool. The glue is ready.

How to dilute glue from finished casein powder? Casein powder is diluted according to the instructions. Usually the proportions of water and glue are equal. The mixture is insisted 40 minutes, after it is ready for use.

On the basis of casein powder (not glue, namely casein), you can make glue, which in quality will be close to industrial:

- 20 g of the substance are combined with 100 ml of water;

- let stand for 30 minutes;

- introduce 6 g of borax;

- 30 minutes to warm the mass in a water bath (at 50 degrees).

Another way to make glue: insist 20 g of casein and 100 ml of water per hour, inject 20 ml of ammonia (25%), 10 ml of caustic soda (50%). If the glue is too thick, it is permissible to dilute it with water.

The following method involves mixing 20 g of casein powder, 4 g of rosin, 40 ml of water, 1 g of slaked lime. After 120 minutes, a hot solution of borax (2 g) and water (12 tablespoons) is made, introduced into the original mass, everything is mixed. Add another 20 ml of water, 2 ml of ammonia. The glue is ready.

to contents ↑Industrial glue production

Usually, glue from rennet casein is made in production. After the preparation of dairy, oil products, a part of the raw material remains, into which the rennet is introduced. According to another technology, glue is prepared by introducing acids, and then casein in the finished form will be called acid-milk.

Skim milk is treated with acid whey, while casein grains are deposited to the bottom. Then it is washed several times so that the grains are compacted. Moisture is removed by centrifugation or pressing. After casein, it is dried, crushed, and the composition is enriched with additional components to obtain glue.

to contents ↑Pros and cons of glue

This tool has a natural origin, and this feature determines both the pros and cons. The material glues wood and other products very reliably, and it is on wood that its adhesive abilities are manifested to the highest degree. A huge advantage can be called cleanliness, environmental friendliness - glue is used even in the manufacture of children's furniture.

Dry powder does not respond to the effects of low or high temperatures, therefore, its storage and transportation are carried out without much difficulty. Material properties are preserved throughout the year in a dry form. Another advantage is the relatively high resistance to moisture. If you add aluminum alum or formalin to the composition, it will be 100% moisture resistant.

Cons of glue:

- the possibility of damage by pests (many insects and animals with pleasure consume powder);

- the risk of dark spots on the products, so it is better not to use glue on light materials;

- short storage time of the finished solution - it will have to be diluted in small portions and work quickly (storage no more than 2-4 hours).

But the useful properties of the material make it highly sought after in the industry, and the demand for glue does not fall. Its price is not high (200-400 rubles per kilogram), and the quality is decent. Glue can be used even in domestic conditions, it is easy to work with it, so the material remains among the leaders among competitors.