When choosing a material for puttying, the putty consumption per 1m2 is not the last value for the buyer. Correctly calculating the cost of a material is not so simple, since many factors must be taken into account. That which affects the consumption of putty mixture will be discussed in this article.

- What affects the flow

- Consumption rates depending on the type of base

- Plaster

- Drywall

- Other types of surfaces

- Putty materials for facades

- Starting putty

- Finishing putty

- Ready putties

What affects the flow

The consumption of putty material largely depends on its intended use. For example, finishing putties are applied in a thin layer, so the cost of such mixtures is not too high. But the base solution performs the function of aligning larger defects, and therefore much more material is consumed. The consumption standards also differ depending on what type of surface is to be processed: for the floor, more putty is needed, for the ceiling - less.

Of great importance is the nature of the surface. If there are a lot of cavities, cracks, elevations on the wall, then much more leveling material will go to such a surface than to an even coating with slight defects.

Not the last role is played by the skill of the performer. A worker with experience, all other things being equal, will always spend less putty than a novice builder. After all, an experienced person has a "full hand", he had previously encountered the implementation of such tasks. In addition, beginners allow more flaws when doing work, leaving uneven places that then have to be further trimmed, wasting putty.

The air temperature, its humidity, as well as the quality of the batch produced have a certain effect.

Putty consumption is also affected by a correctly defined amount of work. Often there are situations when, due to incorrect calculations, the surplus of a mixture already prepared from a dry powder must be thrown away.

to contents ↑Note! Any theory must be tested by practice. The information on the packaging on the flow rate of the solution is a certain average value, without taking into account many variables that can significantly affect the final figures.

Consumption rates depending on the type of base

For puttying, three types of surfaces are distinguished:

- plastered;

- plasterboard;

- others.

Plaster

The consumption of putty on plaster is significantly affected by the external environment. Therefore, when puttying, it is important to comply with the actual operating conditions with recommendations from the manufacturer.

If the plastered surface has no serious flaws and is processed in compliance with the temperature and humidity conditions, the normal consumption of putty corresponds to about one and a half kilograms of the mixture per square meter.

As already reported, the composition type is of considerable importance: the base mixes are consumed in large quantities, and the finish mixes in smaller quantities.So, with a millimeter thickness of the base coat, 1-1.3 kg of mixture per square meter will be needed. But the finish is thinner - only half a millimeter, and therefore the mixture needs only 500-600 grams per square meter. Moreover, in the calculations you must not forget that additional layers of putty will be needed.

As an example, we give the calculation of putty during the processing of the wall. The wall area is 10 square meters. There are small cracks and irregularities on the surface. Below is a simplified calculation for two types of compositions (start and finish):

- The average consumption of the base mixture per square meter of the millimeter layer is 1.15 kilograms. The planned layer thickness is 4 millimeters (4.6 kilograms per square meter). So, for 10 square meters with a 4 mm layer thickness you need 4.6 × 10 = 46 kilograms of dry mix. However, this figure does not take into account the recommended error of 10%. Given the error, the final result will be 50.6 kilograms per square meter (46 + 10% = 50.6).

- The consumption rate of the finishing putty is calculated based on the millimeter thickness of the layer. We consider: 10 × 1.15 = 11.5 kilograms, and taking into account the error (11.5 + 10%), we determine the total consumption of 12.65 kilograms of dry mix per square meter.

to contents ↑Note! The consumption of filler material is affected by the quality of the primer. A well primed surface will require less putty.

Drywall

The rate of gypsum plaster putty consumption (as, by the way, is the case with other materials) depends on the variety of the selected mixture in terms of its components:

- Cement putties are spent most abundantly - 1.2-1.4 kilograms per square meter.

- Plaster mixes are spent less costly - about 1 kilogram per square meter.

- Polymer compositions are the most economical in terms of physical consumption (but also cost more) - about 600 grams per square meter.

It should be noted that it is easier to work with drywall sheets than with plastered surfaces, because of the initially more even surface. The main task is to close up the butt parts, crevices, nail caps. It is also necessary to apply a top coat. Another point: the right amount of putty is easier to determine in advance, given the specific dimensions of the drywall sheet.

to contents ↑Other types of surfaces

Other types of surfaces are primarily concrete and wood. For concrete substrates, the filler consumption per square meter is approximately the same as with plastered surfaces. However, the layer thickness is much higher - about 10-12 millimeters for the base layer. For wooden surfaces, the thickness of the starting layer is much lower - up to 2 millimeters.

Putty materials for facades

The consumption of facade putty is determined by the special conditions in which the surface is to be used. Since the outer part of the building is subjected to many aggressive influences, primarily of a natural nature, the consumption of the facade mixture will be higher than in cases when it comes to interior decoration. Unjustified savings will lead to the fact that the liquid will without special obstacles penetrate into the building structures, which will eventually lead to their decay and destruction. On average, the consumption of facade putty is 1.5 kilograms of material per millimeter layer.

to contents ↑Starting putty

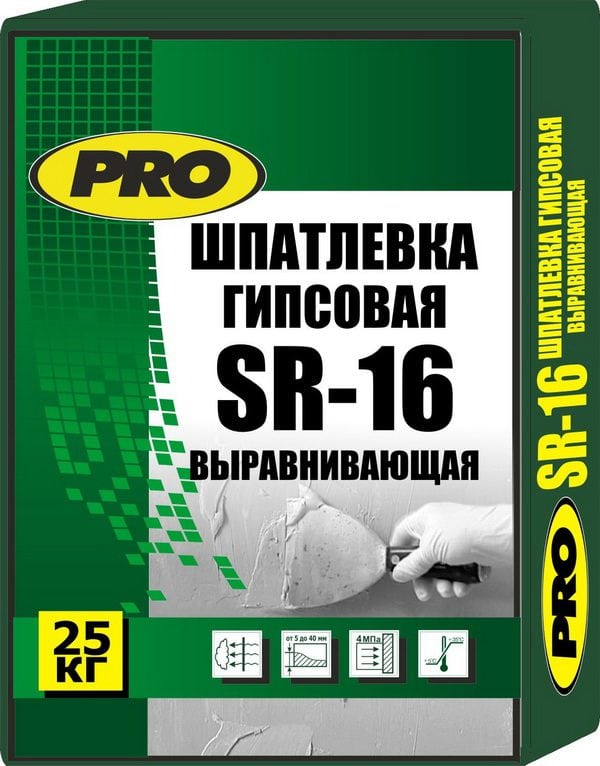

Although cement putty is more common as a starting compound, gypsum mixtures have higher performance. The advantages of gypsum are all the more obvious when it comes to rooms with a moderate level of humidity. On average, the consumption of starting gypsum-based putty is in the range from 0.8 to 1 kilogram per square meter of a millimeter layer. The consumption per square meter in the case of the starting composition is not so important, because the surface quality is much more important.

If the material has many flaws, up to 10 millimeters of putty per layer may be needed. In this case, the consumption can increase up to 8-10 kilograms per square meter. With this thickness, at least two pads are needed, because otherwise the solution will simply fall off.

to contents ↑Note! When calculating the required amount of material, you always need to provide a stock, since the exact expense in advance will still not be possible to calculate. Moreover, the costs, as a rule, are always higher, and not lower than planned. The recommended stock level is 10%.

Finishing putty

Finishing putty consumption is usually more predictable since a more even surface is processed. As a rule, the layer thickness is from 0.5 to 2 millimeters. Average material consumption ranges from 0.5 to 2 kilograms per square meter.

Ready putties

Above we talked about the compositions offered in powder form. However, ready-to-use solutions are also available. Such solutions are much more economical in terms of consumption compared to dry mixes. Moreover, they cost significantly more.

As an example, puttying compound "Shitrok". Putty consumption per 1 m2 is only 500 grams per square meter, provided the millimeter layer. Despite the high cost, “Shitrok” has a number of important advantages (in addition to economical consumption):

- Convenience and ease of use.

- Fast drying.

- Great for various types of surfaces, including drywall.

- It does not contain harmful asbestos.

- The solution is completely ready for use.

So, as can be seen from the above information, calculating the putty consumption per 1 m2 of walls or ceilings is not an easy task, since in order to get a more or less accurate answer, you need to take into account many circumstances. Therefore, most masters plan consumption figures approximately, based on information provided by the manufacturer and allowing a certain level of error.