Glue is a necessary component of many repair work. Laying a tile is not complete without a tiled composition; without wallpaper, a sticker of paintings on the walls. Adhesives are also needed for fastening various parts, repairing broken products. You can buy them in construction and hardware stores, but there is another option - to make yourself, at home.

- The main components of the compositions

- Cooking methods

- Flour glue

- PVA at home

- Epoxy adhesive

- Rubber glue

- Wood glue

- Casein glue

- Dextrin glue for paper

- Heat transfer adhesive

- Glue for shed

- Old linoleum and acetone for glue

- Hot glue making

- Silicate glue

- Food glue

- Additional options

- Glue stick

- Super glue

- Styrofoam Adhesive

- Styrofoam Adhesive

Such material will have a lot of advantages - safety, environmental friendliness, cheapness. Before you make the glue, you need to carefully read the recipe and prepare all the ingredients.

to contents ↑The main components of the compositions

You can make almost any glue with your own hands - complexity can arise only in the selection of the necessary components. A few years ago it was considered the norm to independently make a means for wallpaper, and the canvases could last for decades. Such material was prepared from flour, potato starch, since these products contain a lot of adhesives.

In creating the glue for the tile, cement is required - it is this substance that can hold the tile on the wall. For the manufacture of rubber glue come in handy pieces of old rubber. The clerical includes gelatin and wood glue. There is even a special conductive adhesive, which is used for fastening electrical circuits, mechanisms. Usually, a ready-made “Moment” is taken for its manufacture, grated graphite is introduced, and the electrically conductive composition is ready!

to contents ↑Cooking methods

Some formulations are prepared by simply mixing the ingredients. Others require heating, boiling, or a long aging of substances to dissolve in each other. In any case, it is important to strictly observe the proportions of the components, otherwise the finished home-made glue may not be of good enough quality.

Flour glue

Of course, to buy ready-made glue for wallpaper is much easier. But sometimes it happens that it ends at the wrong time, and it’s quite possible to glue the material own made paste. The same composition is suitable for working with papier-mâché. The recipe is as follows:

- take a container, heat a liter of water in it to a boil;

- in a small amount of cold water, dilute 6 tablespoons of flour to get a homogeneous mass without lumps;

- carefully pour the flour mass into boiling water with a trickle;

- stirring constantly, let the mixture boil;

- cool the glue, which should acquire the consistency of jelly.

You can start gluing the wallpaper immediately after the agent has completely cooled. This amount is enough for 2 rolls of paintings. The glue is best suited for simple paper, light non-woven paper-based wallpaper. For vinyl, other heavy materials it is better to buy ready-made glue.

to contents ↑PVA at home

Domestic PVA and imported "Elmers" are water-based products containing polyvinyl acetate, plasticizers.Depending on the purpose (clerical, household, universal, construction), other substances can be introduced into the composition of PVA. The product has a white or beige color, characterized by the ability to freeze and thaw without loss of quality. With the help of PVA in diluted form, it is possible to prime the walls, and in a pure form it is used for gluing heavy wallpapers.

PVA can be made in this way:

- soak for a day 5 g of photographic gelatin in a small amount of water;

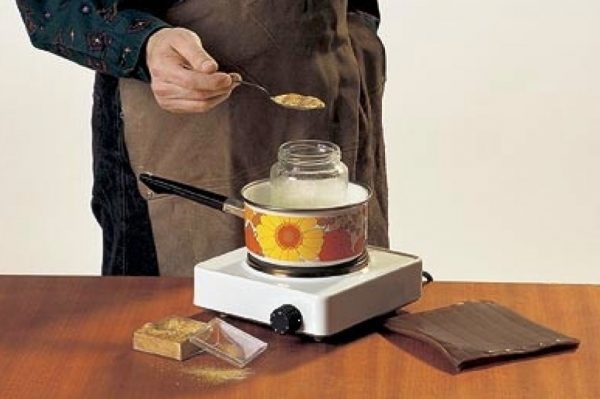

- after 24 hours, take metal dishes, pour a liter of distilled water, put in a water bath;

- separately dilute with cold water 100 g of wheat flour, pour the flour into the water, stirring regularly;

- send the soaked and mixed gelatin there;

- bring the mixture to a boil in a water bath, but do not allow to boil;

- as the mass reaches a consistency of thick sour cream, remove it from the heat;

- pour 4 g of glycerol, 20 ml of alcohol;

- knead well again;

- you can use the product only after complete cooling.

to contents ↑Too thick glue, if necessary, can be diluted with cool distilled water, mix thoroughly. The finished composition must be stored in convenient jars, under a lid at a temperature of + 10 ... + 15 degrees for up to six months.

Epoxy adhesive

It is impossible to cook from improvised means. In any case, it will be required liquid epoxy and hardener, which must be mixed together in certain proportions. Epoxy is a transparent composition that is sold immediately with a hardener. As mixing begins, the polymerization reaction begins, before the end of which it is necessary to have time to apply the composition to the desired surface. Due to its reliability and excellent adhesion, epoxy glue is most often used:

- in shoe manufacturing, repair;

- for gluing plexiglas, plastic, woodwork;

- metal compounds;

- pouring different products;

- in electrical engineering.

Usually, 4-8 parts of hardener require 6-8 parts of resin; more precise recommendations are always indicated in the instructions. After combining the material, it is used immediately or it is slightly heated by putting the container in hot water. After applying the tool to repair various products. It glues the most durable plastics based on etrol, PVC, glassware, metal.

to contents ↑Rubber glue

Such a tool is used for gluing rubber products. Some try to do it like this: cut pieces of an old tire from a car, fill them with gasoline. In fact, cross-linked rubber for tires is poorly soluble in gasoline and other organic solvents, since it contains sulfur. Therefore, the ideal option is to take crude rubber, which is used in the repair of tires with further vulcanization. Gasoline should also be not ordinary, but aviation, then the glue will have excellent quality.

The procedure for creating the tool is as follows:

- finely crush the rubber in a glass jar;

- pour it with a small amount of gasoline so that all the crumbs are covered;

- after swelling, dissolution (from 15 minutes to 1-2 days) add gasoline to the desired consistency of the glue so that it is not too thick or sticky;

- Store glue in a dark, cool place.

Instead of crude rubber, the black soles of old shoes are suitable for the role of filler. It is only important that they be made of TEP (thermoplastic elastomer), which is used for the production of so-called cast shoes.

to contents ↑Wood glue

This adhesive is used to bond wooden products. It can also be used for gluing paper, cardboard, fabric, a number of other materials. His minus is this - from long storage, he will begin to gel, mold, and become covered with a hard crust. The finished product has a not very pleasant smell, which is also its disadvantage.

Joiner glue is a gelatinous mass, quite dense in consistency. Pieces are cut from it, which are heated and used for gluing parts. It is important to warm the composition over low heat to prevent it from boiling. There are several options for making the product.For any of them, you need to purchase dry carpentry glue, which is sold in the form of granules or yellowish tiles. It is prepared from tanning waste, bone meal, animal horns or fish debris.

Popular recipe:

- Grind the glue tile, you can break it with a hammer. Pour in water, leave to swell.

- Put the mass in a tin can or other container, put in a water bath. Heat with constant stirring with a wooden stick. Do not burn the mass!

- After thickening, remove the composition from the fire, add 950 g for every 720 g of vodka mass. Also add 12 g of powder alum per 100 g of finished glue.

This tool has water-repellent qualities, gives glued products high strength. Also, wood glue is made according to another recipe:

- pour 1 kg of adhesive granules into the container;

- pour water, leave to swell (usually 1 liter is enough);

- after the product has the texture of a jelly, put the container in a water bath;

- bring the mass to a liquid state, preventing it from burning, constantly stirring;

- add 1 liter of vinegar (9%) to the mass removed from the heat, mix, and the glue is ready.

to contents ↑You can also dilute the glue with water 1: 1, then add as much glycerol as dry glue powder was taken. Then you need to warm the mass in a water bath until the liquid evaporates. After that you can immediately use glue. It is dried for storage, and before use it is simply allowed to swell in water.

Casein glue

Casein is a complex protein that is obtained from caseinogen in the process of curdling milk. Casein glue It is used for gluing leather, wooden products, paper, cardboard. To make such a substance, you need to isolate casein from cottage cheese by degreasing:

- pour cottage cheese with water (1 l) with soda (2 tablespoons);

- leave for 20 minutes;

- rinse cottage cheese from the tap, let the water drain, dry the product;

- allow the mass to harden, then grind to a powder state.

Dry casein can be used to make glue. Powder (100 g) put on fire in a saucepan, add 200 ml of water in a thin stream. The heated mass should become thick, uniform, for which it must be mixed very carefully. If necessary, the product can be well broken with a blender. After cooling with glue, it is possible to connect various products. It is advisable to make small portions, because it is stored for a short time - up to 3 hours, then hardens.

to contents ↑Dextrin glue for paper

Dextrin glue is well suited for cardboard, paper, because it is widely used in needlework, children's art, for origami and quilling. Instead of store dextrin ordinary starch is quite suitable. It is placed in a dish made of heat-resistant material, sent to the oven for 1.5 hours (at +160 degrees). After its splitting and turning into dextrin, you can prepare glue:

- take 3 tablespoons of dextrin;

- pour 5 tablespoons of water;

- heat to dissolve the powder;

- introduce 1 tablespoon of glycerin;

- the glue is ready.

Heat transfer adhesive

Similar tools are sold in radio parts stores. Also heat transfer adhesive do it yourself. You need to take glycerin, heat it to a temperature of +200 degrees to evaporate water. In the oven, heat zinc oxide to a maximum temperature. Mix both components equally, mix, cool. Use glue to connect quickly heating parts where it is not possible to use a different type of fastening.

to contents ↑Glue for shed

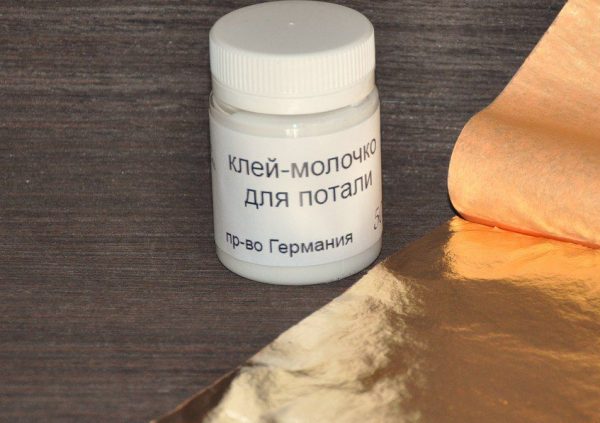

Potal - alloys with the inclusion of precious metals in the form of thin sheets. They are used for gilding, silvering ceramics, stucco, metal, wood or glass. Typically, glues based on alcohol, oil, acrylic or water are used to process products. You can replace them with a homemade composition:

- combine 100 ml of cream and cognac;

- apply the product on the treated surface;

- after 30 minutes proceed to gilding.

You can also use a different recipe. Dissolve 70 g of sugar in 200 ml of warm water, allow to boil. Pour 1 teaspoon of vinegar essence, cook for 30 seconds.Remove from heat, introduce 1/3 cup starch. The tool should consistency resemble sour cream. When the glue has cooled, you can use it for gilding. After solidification, it will become transparent.

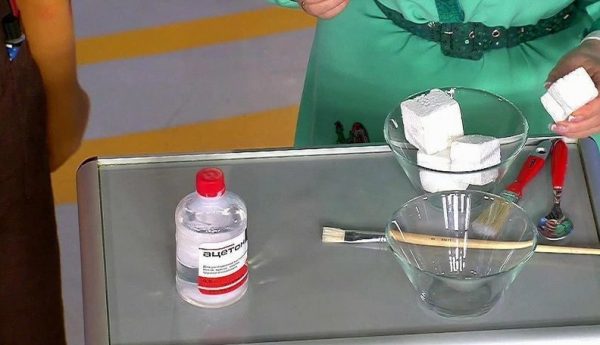

to contents ↑Old linoleum and acetone for glue

The finished product from these components can be used for gluing ceiling blocks, PVC products, glass. It is enough to find the scraps of old linoleum and grind them into small pieces. After linoleum is poured with acetone, and the latter should be 2 times more.

to contents ↑The jar with the future adhesive composition must be tightly closed. Put it in the dark for 12 hours. During this period, linoleum will dissolve in acetone, and the glue will be ready. It can be immediately applied to the above materials, as well as for gluing leather, wood, and ceramics.

Hot glue making

Hot glue is useful for bonding wooden surfaces, repairing products from particleboard, fiberboard. For the manufacture you need to take 35 g of drying oil, 100 g of finished wood glue. The latter must be heated in a water bath until it becomes liquid, then enter the drying oil. You can use the tool immediately, including for laying tiles.

Silicate glue

It is difficult to make silicate glue at home. It is prepared by combining quartz sand, potassium silicate or sodium, and at a constantly high temperature. The manufacture of a substance is available only in industrial conditions, less often it is done by builders, again, with equipment.

to contents ↑Food glue

The so-called food glue is used to decorate cakes - attach figures on their surface, or other heavy decor. There are 2 options for making glue:

- Mix 4 tablespoons of starch, 1 cup of cold water. Cook a thick jelly, cool to get a sticky mass.

- Take 250 g of sugar, 100 ml of water. Make caramel that has sticky properties.

Additional options

Less commonly, users try to make other types of glue that serve as an alternative to store products.

Glue stick

An adhesive pencil is made from PVA. For the case, you need to take the old packaging from the antiperspirant deodorant, which closes tightly. Cut the laundry soap (2 parts), pour water (1 part). Dissolve in a water bath, pour 4 tablespoons of PVA, cool. After putting the mass into the package, let it harden.

to contents ↑Super glue

Of course, it will not work to make a real super-glue - it is prepared from cyanoacrylate with the addition of a number of complex chemical components. But a very reliable composition can still be created with your own hands. To do this, you will need:

- 125 g of wood glue;

- 100 g of sugar;

- 35 g slaked lime;

- 450 ml of water.

Sugar is dissolved in water, lime is added, heated for 30 minutes in a water bath. Next, crushed carpentry glue is placed in the solution, boiled until the mass is homogeneous. The tool can be used for bonding metal, ceramics, porcelain.

to contents ↑Styrofoam Adhesive

Best for sticking foam is carpentry glue. Casein glue is also suitable, which is mixed in equal parts with hydrated lime. Such a tool is ideal for attaching polystyrene when warming a house.

Styrofoam Adhesive

Glue is made from acetone and foam for connecting elements of glass, metal, wood. The foam is crushed into crumbs, poured with acetone to completely cover it. The viscous mass is obtained almost immediately, it can be used as ordinary glue, after mixing well.

By making adhesives with your own hands you can seriously save money, especially if a large repair is planned in the house or apartment. The quality of the finished product may be slightly inferior to the store, but it will certainly be safe for health and affordable!

Hello. Can you teach how to make acrylic glue to create a flexible stone?