Improved stucco is an unusual term, but only for beginner finishers. Professionals are well acquainted with the basic concepts found in estimates, and they know for sure the differences between ordinary material and its more “advanced” types.

- Types of plaster

- The main differences between improved plaster

- Technological features

- Composition requirements and tolerances

- Quality control of plastering

- Scope of the improved plaster

- Application technology

- Wall preparation

- Mixing the ingredients of the solution

- Layer thickness

- Splashing

- Soil application

- Final layer

- Approximate prices for plasterer services

Types of plaster

The standards for the work are regulated by SNiP 3.04.01-87 “Insulating and finishing coatings”. The rules describe three types of plastering, which vary greatly in quality and complexity.

For work, the following types of material are used:

- Simple. Suitable for decoration of non-residential premises, as well as for houses, apartments with low requirements for smoothness, evenness of walls. It may have a rough texture, applied only in 2 layers (spraying, priming).

- Superior. It is used for interior decoration of residential premises, offices and industrial buildings, if high quality requirements are imposed on the base. After processing, the surface is smooth, ready for finishing with tiles, mosaics, and wallpaper. In addition to spraying and priming, work involves coating.

- High quality. It is distinguished by the fact that after coating, another additional priming is performed. This helps to make the surface perfectly smooth.

The main differences between improved plaster

It seriously differs from the usual one in some features and application technology. The composition of the material, on the contrary, can be similar, include all standard components without any modifiers. Nevertheless, many manufacturers introduce reinforcing components or increase the amount of cement, therefore, after drying, the coating will have great mechanical resistance.

It does not crack, becomes moisture resistant, and can be used in wet rooms. Occasionally, PVA is added to the composition as an additional binding component.

The main differences of such a material with the usual lie in technological features, the quality of the finished lining:

- the surface is flat, smooth, you can immediately glue thin wallpaper or other delicate materials on it;

- the layer thickness reaches 15 mm (a simple indicator does not exceed 12 mm);

- when applying the product, the quality is regularly checked by the building level vertically, horizontally, diagonally.

The material is used if it is planned by the estimate, because the cost of such work will be an order of magnitude higher. Most often, the technology is practiced during repairs in offices, cultural and educational facilities, in apartments where the walls are to be painted, varnished, and finished with high-quality wallpaper.

to contents ↑Technological features

The initial stages do not differ from other types of plastering surfaces. The first step is to spray the base, then the primer (top coat), and after coating. The specificity of plastering works is also available:

- the spray is made with a liquid solution of the mixture, then the mass is distributed without much equalization (layer thickness - up to 5 mm);

- priming is carried out with a thick solution resembling dough, while the size of the sand fraction does not exceed 2.5 mm (the thickness of the primer layer is up to 7-8 mm);

- nakryvka perform a thin layer (up to 2-3 mm), and a solution for this stage is prepared in the same way as for spraying (like liquid sour cream).

Using the improved plastering technique, it is possible to finish the foundation with the most difficult terrain, which is due to the optimal layer thickness, technology features.

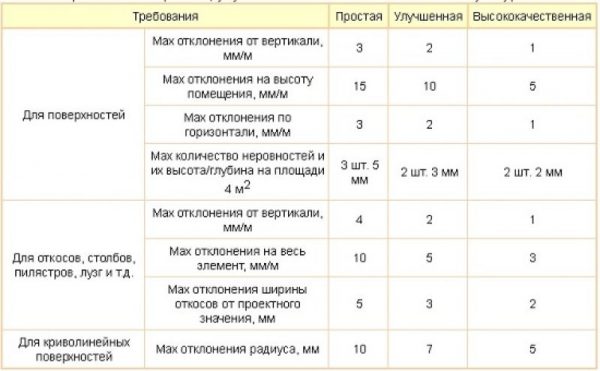

to contents ↑Composition requirements and tolerances

Strict requirements are imposed on building mixes concerning such indicators:

- number of layers, their thickness;

- deviation of the surface from the level vertically (not more than 1 mm per square meter, not more than 5 mm to the entire height of the room);

- deviation of the surface from the horizontal level (not more than 1 mm per square meter);

- error on waves (up to 2 irregularities for every 4 square meters, wave depth - less than 2 mm).

After drying, tuberosity, cracks, chips, gaps, other defects on the surface should be absent. It also evaluates the strength of the finish, its resistance to moisture, mechanical stress. As for the composition of the improved plaster, it may contain sand, quartz chips, cement, gypsum, lime, various polymers, antibacterial components, improving additives.

to contents ↑Quality control of plastering

Plastering is the most time-consuming part of the decoration process. If you make them of poor quality, then the walls will remain uneven, with the fair lining of the master there will be a lot of trouble. Therefore, during application, it is important to timely measure the surface using a two-meter level. The laser level is considered a more advanced tool, and the simplest is a regular plumb line, which can also be used during operation.

After puttying the corners, you also need to evaluate the quality of the finish. To find out if the angle corresponds to the set 90 degrees, use a construction square with a shoulder of 50 cm or more. An ordinary tape measure is also suitable: it measures the diagonals of walls and compares them with each other: the numbers should be the same. If deviations are observed during measurements, then the evenness of the angles is doubtful, the work is subject to alteration.

to contents ↑Scope of the improved plaster

The material is suitable for any room where you want to get a perfectly flat base. In addition to finishing the inner surface of the walls, improved plaster is used for repairs:

- brick, concrete foundations outdoors;

- wooden, mixed surfaces;

- areas around doors, window openings, cornices, columns;

- ceilings in rooms for various purposes.

Application technology

Without proper experience, coping will be problematic. Technology requires strict compliance at all stages.

Wall preparation

Preparatory measures include the removal from the walls of the remains of the old coating, the elimination of falling pieces. Large pits, chips, other defects putty cement-sand mixture. Cracks are closed using reinforcing tapes. The entire surface of the walls or ceiling is primed with a deep penetration agent to further improve grip.

to contents ↑Mixing the ingredients of the solution

Most often you have to work with the finished mixture. Professionals prefer compositions of famous brands, which obviously have excellent quality and have all the necessary properties. If you wish, you can independently prepare the composition, which will save money:

- combine sand and cement in a ratio of 2: 1;

- add 3 parts slaked lime to 3 parts of the mixture;

- prepare clean room temperature water and PVA glue.

Typically, 10-20 liters of water is poured into a convenient container, 100-200 g of PVA glue is introduced, and it is thoroughly dissolved. After they begin to gradually pour the finished dry mixture, immediately thoroughly whipping the mass with a construction mixer. The plaster is added to obtain the required consistency (depending on the stage of work).

to contents ↑Thanks to PVA, the mixture will not crack on the wall after drying, and it will become much easier to apply. In the presence of serious defects on the surface, gypsum can be introduced into the composition to increase strength and adhesion.

Layer thickness

The total thickness of the applied improved plaster is 1.5 cm, while the first layer is 5 mm, the second is up to 8 mm, the third is the thinnest (2-3 mm). If the walls have large irregularities, because of which it is impossible to maintain such a thickness, its increase by 2-5 mm is permissible.

Splashing

After preparation of the solution, which by its consistency resembles sour cream, the first stage of finishing work is carried out. Plaster fills all defects well, evens out waves, removes cracks. It is as if thrown onto the wall in small portions, and it is more convenient to do this with a special plaster bucket. After carefully rubbing the composition, carefully closing the bumps.

to contents ↑Soil application

Priming is done with a thick solution, which is applied with a trowel and rubbed with a trowel. The tool is held at an angle of 150 degrees, movements are performed first sideways, then from the bottom up. The evenness of the layer is checked by the level; upon detection of defects, the surface is straightened.

It is the soil that allows you to give the wall a perfect evenness, so it is applied especially carefully.

Final layer

The overlay, or final layer, is performed as follows:

- dried soil is slightly sprayed with water;

- brush with a nakryvka in several of the thinnest layers;

- align the napping with a wooden trowel after partially drying it - first make circular movements, then vertical and horizontal;

- give the wall to dry completely (up to 2-3 days).

Approximate prices for plasterer services

Typically, working with cement mixtures is estimated to be slightly more expensive than with gypsum, due to the complexity of the application. Approximate prices for plastering walls are as follows:

- simple plastering - 230-260 rubles / sq. m;

- improved - 310-360 rubles / sq. m;

- high-quality - 390-450 rubles / sq. m

It is recommended that experienced crews be invited to perform work, since in practice many craftsmen try to save on labor costs and do not follow the indicated sequence of layers. If technology is strictly followed, the result will be perfectly aligned, smooth walls that are perfect for any decoration!

It was enough to bring the table.