Professionals recommend that all finishing work in the summer, in good weather. This is due to the peculiarities of applying, setting and drying the applied compositions - plasters, putties, other building mixtures.

- Features and types of plaster

- Temperature for plastering

- Outside

- Inside the house

- Specifics of work at negative temperature

- What threatens non-compliance with the temperature regime

- Frost-resistant plaster: types

- Chlorine water

- Potash

- Ammonia water

- Modern materials

- Wall preparation

- How to dry plaster in winter

- Ways to warm up the premises for work in winter

But it is not always possible to make repairs in the warm season: sometimes you have to work in the autumn or winter, when the air warms up badly and it is cold outside. It is necessary to understand in advance at what temperature it is possible to plaster, and what is the specificity of repair indoors and outdoors.

Features and types of plaster

Plastering works are carried out to protect surfaces from damage, leveling, as well as improve their aesthetic appeal. For plastering walls, ceilings, various structures, different types of mortars are used:

- cement-sand - the most popular, inexpensive, easy to prepare with their own hands;

- cement-lime-sand - after replacing part of the cement with lime they gain lightness, plasticity, however, they lose a little in strength;

- gypsum and gypsum-lime - are used indoors, are not suitable for the street, because they do not withstand humidity and temperature extremes;

- acrylic - due to the presence of acrylic resins gain increased moisture resistance, excellent adhesion with all building bases;

- silicone - moisture resistant, durable, reliable, vapor permeable, but the most expensive;

- silicate - compositions based on potash glass with increased strength, ideal for outdoor applications.

to contents ↑When choosing a plaster, many factors are taken into account - the ambient temperature, the drying conditions of the coating, the application method, humidity, etc. Also, for plastering surfaces, various additives are used to the compositions, which not only improve their technical characteristics, but also expand the temperature regime during application.

Temperature for plastering

When carrying out work in the winter on the street or in an unheated room, it is important to determine at what temperature this can be done, and when it is better to postpone the decoration.

Outside

There are building codes that determine the temperature regime for applying plaster on building facades:

- the air should warm up to at least +8 degrees, although some mixtures can be applied at +5 degrees (we are talking about the operating time and the drying period of the composition);

- provided that special frost-resistant additives are added to the plaster, work can be carried out even in frost (the specific minimum temperature is always indicated on the package);

- the temperature of the mixture itself should also not be lower than +8 degrees, which is especially important with the machine method of plastering;

- on the day the plaster is applied, there should be no wind, as well as any precipitation;

- it is important that wall thawing already occurs by more than ½ thickness;

- if it is not possible to comply with these conditions, walls or other street structures can be temporarily insulated.

Also, during the period of plastering, it is necessary to ensure that the humidity of the surface of the object is not higher than 8%. Dry the base and remove the formed ice will help heat gun or building hair dryer. Using these tools to prepare the surface can not only be easier, but also more reliable. “The old fashioned way” should not be to wet the walls with hot water: this will unnecessarily moisten the base, make the finished plaster layer unstable, which is why it will soon become a layer.

to contents ↑Inside the house

If there is no heating in the room, a number of important conditions will also have to be observed during the finishing work. The air temperature here should not fall below +8 degrees on the day the plaster is applied and not lower than + 5 ... + 8 degrees - when drying it.

It should be remembered that the period of complete drying of cement mixtures is up to 14 days, gypsum and lime compositions - 7-8 days. At least twice a day for this period, it is necessary to ventilate the room to get rid of excess moisture. Building mixtures based on synthetic components may not require ventilation, which is always indicated on the packaging.

As for the surface temperature of the walls in unheated rooms, then at a height of 50 cm from the floor (at the coldest point), it must be at least +8 degrees. The ceiling temperature must be no higher than +30 degrees. If these conditions are not met, anti-frost additives are added to the plaster, or the room is heated. When the walls are heated to ½ of their thickness, you can start plastering.

to contents ↑Specifics of work at negative temperature

Facade plastering at subzero temperatures is carried out only with mixtures in which special chemicals are introduced. The latter provide a reliable setting of the composition even in the cold, because it is almost impossible to warm the facade so that the plaster solidifies in the normal mode. Only at a moderately low temperature can powerful heat guns be used to heat the wall to + 18 ... + 20 degrees, and then apply plaster.

The need for additives is due to the fact that ordinary mortar does not dry in the cold, but freezes. As a result, after warming, the plaster layer begins to fall off in pieces. If modifiers are introduced into the mass, it does not lose its properties and retains plasticity until it completely hardens. It is important to remember that slopes and other areas that are most severely affected by adverse factors cannot be plastered at freezing temperatures. This work will have to be left until spring, since in winter a reliable layer of plaster will not form here.

to contents ↑

What threatens non-compliance with the temperature regime

With a short-term deviation from the temperature regime or its violation to insignificant limits, the plastered walls usually lose perfect evenness, since the coating becomes wavy. Often the walls “float” a little - the finish is deformed and slides under its own weight.

If technological deviations were more serious, this can cause a host of other problems:

- the appearance of a network of cracks or very deep cracks;

- loss of adhesion of the plaster with the base;

- collapse of the entire layer of the building mixture.

Frost-resistant plaster: types

To enhance frost resistance, special additives are introduced into the plaster, which can be either home-made or ready-made. Most often they use chlorine water, potash, ammonia water, less often - potassium chloride, sodium chloride. The last two additives are not so popular, because after the onset of heat they can cause efflorescence on the surface of the solution.

Chlorine water

If you start building mixture not on ordinary, but on chlorine water, then you can work with it up to –25 degrees below zero. They apply such a composition as standard, not particularly caring for the technology, but only monitoring the thickness of the layer (it should not be too large). To prepare the product, the water is heated to +35 degrees, 1.5 kg of bleach are introduced for every 10 liters of liquid, mix well. After dissolving the lime composition is removed under the lid for 1.5 hours, then use it as needed. On such water, cement and other plasters are prepared for finishing wood, concrete, and brick. Work with bleach only with gloves, protective clothing and a respirator!

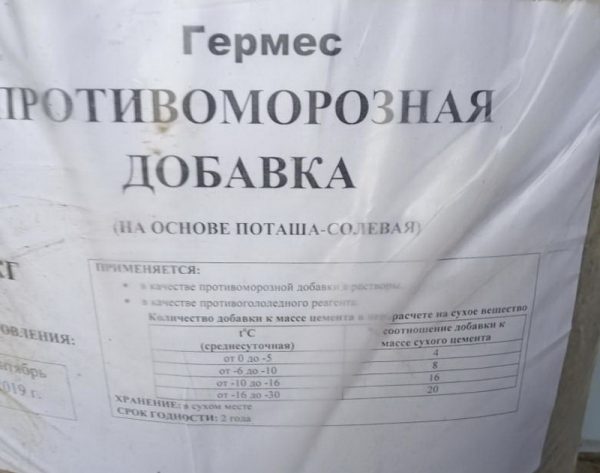

Potash

Potash (potassium carbonate) is ideal for preparing plaster, which is used for processing reinforced structures. This is due to the lack of risk of corrosion damage from the addition of this substance. Potash allows you to give the solution protective properties, increase resistance to precipitation, temperature extremes and other adverse factors.

Potash solution is widely used for diluting cement, clay, lime mortars, while the use of cement of the lowest grades is allowed. If the ambient temperature is not lower than –5 degrees, 1% of dry potash of the total mass is introduced. At lower temperatures add about 1.5-2% of the substance. A cement mortar with sand is prepared on the basis of a ratio of 1: 3, after which it is diluted with water and an aqueous solution of already measured potash is added.

to contents ↑Ammonia water

This homemade additive also has high efficiency and is able to optimize the properties of plaster in the winter. Ammonia water allows you to work with solutions even at –30 degrees, although such conditions will be extremely unfavorable even for the master himself.

This additive is well suited only for working with cement and cement-lime mixtures and is completely unsuitable for diluting compositions with gypsum, clay. Ammonia water is added to the finished plaster, and its concentration in the solution should be 6%. To do this, take an industrial 25% composition in a volume of 1 liter, add 3.16 liters of water with a temperature not exceeding 5 degrees (at a higher temperature, ammonia will begin to evaporate). If the initial ammonia composition has a 15% concentration, then 1.5 liters of water is required per 1 liter of it.

to contents ↑When adding ammonia water, the temperature of the plaster must be measured and compared with the ambient temperature. If it is –15 degrees outside, then the solution should have a temperature of about + 2 ... + 3 degrees. At –25 ... –30 degrees outside, warmer plaster is needed (approximately +5 degrees).

Modern materials

Now, in construction stores, ready-made additives based on synthetic components have appeared that allow plastering at temperatures up to –50 degrees. They give the mixture durability, strength, water resistance, elasticity, accelerate its drying. Such substances do not cause efflorescence, which compares favorably with some home-made additives. Such tools also have a minus: plasters based on them are distinguished by a large weight (almost 1.5 times heavier than standard ones).

On sale you can find both dry additives and plasters with frost-resistant components already introduced into their composition. The most popular brands are:

- BERGAUF;

- VETONIT;

- HENKEL;

- "Remix".

Wall preparation

The object on which plastering is planned in the cold season must be carefully prepared for work.The durability of the plaster layer will directly depend on the quality of the preparation. The walls are cleaned of ice and snow, mainly by mechanical means (do not use boiling water, which then will itself become ice). Also, the remains of masonry mortar, efflorescence, and spots of fat are removed from the surface.

Seams and cracks are filled separately with the mortar; on the facades, notches are made to enhance adhesion. The walls are primed, allowed to dry, and only then begin to work.

to contents ↑How to dry plaster in winter

Since plaster solutions have a different composition, they require different conditions for drying. For example, building mixtures with lime need carbon dioxide from the air: this is the only way they will remain strong when dried. Therefore, with forced acceleration of the process, the plaster layer will not turn out to be strong and reliable. Ventilate the room regularly for 1.5-2 weeks to ensure sufficient airflow.

to contents ↑If we are talking about gypsum mortar, it also needs to be dried with daily airing, but without drafts. For example, in winter, you can leave only a small gap in the window to allow the air to refresh. Cement plasters dry up to 2 weeks, and they do not need ventilation, but they need sufficient humidity (50-60%).

Ways to warm up the premises for work in winter

To maintain the required temperature in the room (about +8 degrees and above), different heating options can be used. If central heating or heating with a stove is not available, use air heaters, air heaters. Such devices create a favorable microclimate even in large rooms. Carbon monoxide, which appears during the operation of the heaters, is discharged through a tube.

"Temporary heating" will provide favorable conditions for drying the plaster layer in the winter. Having such equipment, it is not necessary to wait for the onset of summer, because you can carry out all repairs in your free time from other activities.