For plastering the walls, you need to choose the right building mixture, which will create a strong, reliable and durable coating. An example of excellent material for interior and exterior use is Volma plaster. It is available in different versions, but they all have common features: high quality and excellent technical specifications.

- Material Features

- Types of plaster

- Scope of application

- Specifications

- Composition

- Shades

- Layer thickness

- Adhesion and strength

- Frost resistance and water absorption

- Stucco Tips

- Solution preparation

- Surface preparation

- Tools for work

- Trial application

- Sequence of operations

- Surface decoration

- Material consumption

- Advantages and disadvantages

- Price and packaging

- Terms and conditions of storage

Material Features

The assortment of Volma domestic finishing materials is quite rich: there are no less products on the shelves of stores than famous foreign brands. Many craftsmen call the brand the "answer" to the German "Rotband", which is an order of magnitude more expensive. Among the Volma product line, you can find plaster for any kind of work: there are rough leveling, finishing and even decorative materials.

The composition of plasters includes only environmentally friendly, safe for humans and the environment components. Minerals are the main share among them, but there are modern synthetic ingredients, as well as fillers and binders. Some plasters are applied only by hand, others are intended for machine application.

to contents ↑Types of plaster

All types of plaster of this brand can be divided into the main component, which forms the basis of the building mixture:

- gypsum - contain gypsum, with some exceptions, are recommended only for internal work;

- cement - ideal for all types of work, are considered universal.

Depending on the purpose, all the plasters can be divided into those that are suitable for rough (preparatory and leveling) work, to maintain the microclimate in the room, to increase the strength of surfaces, etc.

Here are examples of the assortment of Volma brand products:

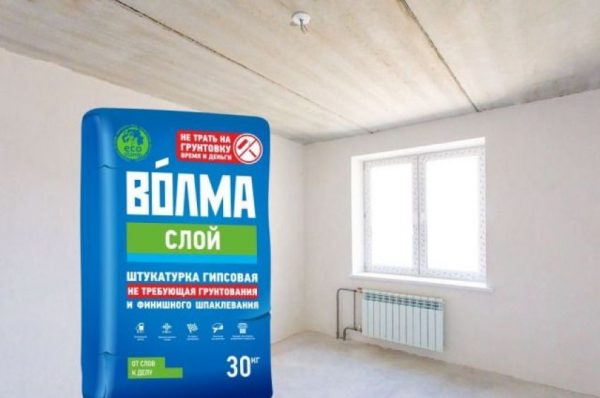

- "Layer". Gypsum mixture based on a light binder with the addition of chemical components to increase adhesion and optimize water-holding ability.

- "Layer Titan." High-strength gypsum plaster with increased adhesion to surfaces.

- Layer Ultra. Plaster-free material based on plaster.

- "Canvas". Lightweight dry mix for manual application with mineral and synthetic additives.

- "Plast". A special material for easy alignment of walls and ceilings, plastic, can be used for decorative finishes.

- "Lux". Super lightweight, thin layer plaster for aerated concrete, also suitable for foam concrete.

- "Start". Starting gypsum material, suitable for walls, ceilings inside heated rooms with normal humidity.

- "Title". Plaster material for finishing work that does not require subsequent puttying.

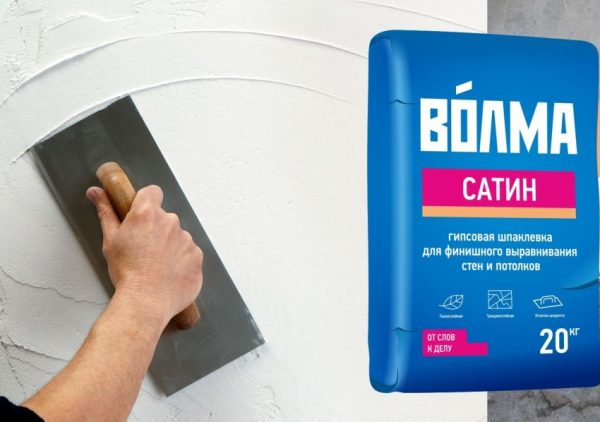

- "Gloss". Material applied for subsequent finishing puttying.

- Aqualit. Dry plaster mix for finishing rooms with high humidity, suitable for application under tiles.

- Aquasloy. Cement leveling material with modern polymer and mineral additives and modifiers.

- "Bark beetle" and "Fur coat". Decorative plasters to create a unique texture contain white Portland cement, microfiber, modifiers and fractional stone chips.

- "Base". High strength cement plaster. Designed for finishing the basement and other outdoor work.

- Gypsum asset. A mixture for professional machine application. It has a variety - "Gypsum-asset Extra" with increased resistance to cracking.

- "Tandem". A universal mixture that can serve as plaster and putty.

Scope of application

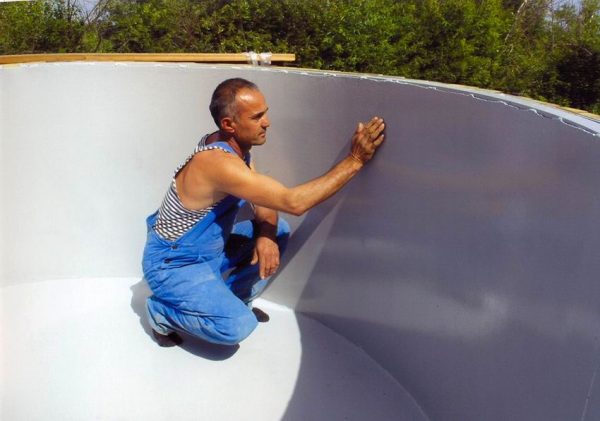

Building compounds of the Volma brand can be selected for any situation. The range includes products for rooms with different types of humidity, including baths, showers, kitchens, saunas and pools. Volma is suitable for applying to all types of building foundations - brick, concrete, aerated concrete, gypsum concrete, foam concrete, chipboard, OSB, cement-lime coatings.

to contents ↑Shukaturkami can be used to decorate different rooms, applied to walls, ceilings, partitions, niches, arches. Many products are suitable for facade work, cladding socles, unheated buildings.

Specifications

“Volma” plasters may differ from each other in technical parameters, which depends on the components included. There are averaged characteristics. So, the time to complete drying of most mixtures is 5-7 days, and the recommended temperature for working with them is + 5 ... + 30 degrees. After hardening, the plaster layer tolerates temperature differences within –40 ... + 60 degrees. The initial setting time of the layer is 20-40 minutes, the final setting occurs in 180 minutes.

to contents ↑Composition

“Volma” plasters are made on a cement or gypsum basis. Also, to increase strength, stickiness and other positive properties, stabilizers, modifiers, plasticizers, frost-resistant additives, anti-caking agents, etc. are introduced into the composition of materials.

Shades

Mixes are presented in gray, beige, light yellow options. They are usually used to level various surfaces. Those “Volma” plasters that are intended for finishing are sold in white. White mixtures can be tinted with dry pigments, but this is in demand, except in relation to decorative plasters. If desired, after drying, they can be painted with any silicate, silicone, acrylic paints.

to contents ↑Layer thickness

The recommended layer thickness when working with these types of building materials is 5-30 mm. The permissible thickness of the plaster layer is 6 cm, but only with the preliminary reinforcement. The minimum layer that can be applied is limited by the grain size of the filler, and in its absence, by an indicator of 3 mm.

Adhesion and strength

All Volma plasters are characterized by a high degree of adhesion with building materials. Their compressive strength is 3.5 MPa, and their bending strength is 1.5 MPa.

Frost resistance and water absorption

Due to the presence of special additives that increase resistance to low temperatures, some plasters withstand up to 75-100 freezing and thawing cycles. Most of them tolerate a drop in temperature to –40 degrees, and some mixtures (for example, “Bark beetle”) - up to –50 degrees. All formulations are characterized by a low degree of water absorption.

Stucco Tips

When working with plaster mixes, it is necessary to ensure optimal environmental conditions (temperature within + 5 ... + 30 degrees, humidity not higher than 80%). If the humidity in the room is too high, the plaster layer will swell or peel off. You can not process the walls if they are frozen - you have to wait until the temperature rises outdoors or indoors.

The solution is diluted in small portions, because after 20 minutes the top layer of gypsum in the container begins to set, and you need to have time to apply the mixture to the surface.The substrate is prepared carefully, since with poor quality of the base, the adhesion of the plaster is reduced. Before painting the plastered walls or wallpapering, it is important to make sure that the plaster is completely dry.

to contents ↑Solution preparation

The exact proportions of the dry mix and water are always indicated on the plaster packaging. On average, 0.6 kg of clean, cool water is needed per kg of powder. First, a measured volume of liquid is poured into a plastic container, after which powder is gradually poured, thoroughly mixing the product with a construction mixer.

Before applying to the walls, the plaster should have the consistency of sour cream, in which there are no lumps and foreign inclusions. If the mass spreads, it means that it is not properly prepared, and there is too much water in it.

to contents ↑Surface preparation

Before plastering, prepare the foundation - a wall, ceiling or other area. It is cleaned of the old coating, peeling, crumbling pieces of paint and putty are completely removed. Dirt, greasy and oily stains are wiped off with solvent. Metal parts are treated with anti-corrosion compounds, otherwise they will quickly rust under a layer of plaster. In addition, the following are being undertaken as training measures:

- clean the walls from traces of mold, fungus, treat the entire surface with an antiseptic (this is especially important if the work is carried out in a humid room);

- remove traces of efflorescence (salt deposits);

- large cavities are covered with a cement mixture, cracks are embroidered and also lubricated;

- apply 1-2 coats of primer (only “Volma Layer” does not require preliminary priming, as indicated on the packaging).

to contents ↑As a primer, it is better to use compounds that are produced by the same company - Volma Universal for highly absorbent substrates, Volma-Contact based on acrylic dispersion and mineral additives. You can also use the primer Volma-Interior, which is suitable for preparing surfaces for painting and applying decorative plasters.

Tools for work

“Volma” gypsum plaster is applied using standard building tools that are suitable for working with any mixes. For manual plastering you will need:

- spatula, trowel, trowel or ironing machine for applying the product to the wall;

- rule in the form of "H" for leveling the plaster layer;

- a wide spatula or a rule in the form of a trapezoid to trim the solution;

- a polystyrene and polyurethane construction grater for mashing the composition;

- large metal spatula for gloss;

- scissors for metal and beacons for leveling walls using beacon technology;

- level for determining deviations of the plane.

Of consumables, fiberglass mesh, rags, masking tape for protective gluing of different surfaces may be required.

to contents ↑Trial application

At the very beginning of the work, the masters advise diluting a small amount of the mixture for trial application. This will help determine the exact setting time of the composition, with its consumption for a certain area, with the labor required for leveling. The thickness of the layer is also set at this stage, then to comply with this indicator.

Sequence of operations

Surface treatment with gypsum or cement plasters of the Volma brand is carried out in this way:

- Leveling the base. Throw the solution on the wall with a trowel or trowel. Align the plaster layer with the rule, moving it from top to bottom between pre-installed beacons. Excess solution is removed and removed, and also the recesses appearing are sealed with them.

- Pruning. After about 40-60 minutes, when the plaster sets, small roughnesses are overwritten with the rule.If you plan to decorate the walls with tiles, further steps are skipped.

- Smoothing down. Immediately after cutting the solution, spray the wall with water, wipe it with a building grater until a “milk” appears on the surface. They carefully grind even the smallest roughness, smooth the pores.

- Glossy. Wet metal grater produces surface treatment to make it perfectly smooth.

- Padding. If you plan to paint the wall with paint, apply a layer of a suitable primer to the plaster.

Surface decoration

Using Wave mixtures, different surfaces are decorated. For example, directly through a layer of non-hardened material, they are drawn with textured rollers to create an interesting relief. The drawing can be done on a wet basis and using stencils, pressing them into the plaster, as well as “drawing” with the sharp end of a spatula, another construction tool, a hard brush, a sponge grater. The dried white plaster is decorated by coloring, different types of painting.

to contents ↑Material consumption

To calculate the exact consumption, you will have to take into account many different factors - the type of plaster, the thickness of the layer, the degree of curvature of the surface, the type of base material, the technique of applying the composition. This can be done using online calculators, although it is easier to see the approximate consumption on the packaging of the building mixture and buy material with a small margin.

Examples of consumption of “Volma” plasters per 1 cm thick layer, depending on the specific type, are as follows:

- “Layer” - 8-9 kg / sq. m;

- "Plast" - 10 kg / sq. m;

- “Canvas” - 9-10 kg / sq. m;

- "Base" - 15 kg / sq. m

Advantages and disadvantages

Among the advantages of Volma construction mixtures, it should be indicated:

- frost resistance, resistance to temperature extremes;

- high adhesion with most materials;

- environmental cleanliness;

- low consumption;

- simplicity in drawing and the subsequent operation;

- microclimate optimization in the house;

- getting a flat, smooth surface;

- plasticity, elasticity of the material;

- lack of shrinkage of the plaster layer, its cracking and detachment;

- prevention of the development of fungus, bacteria;

- reasonable price and high quality.

The disadvantages include the fact that sometimes in the packaging of the plaster large mineral particles can be present that can spoil the finish layer if they are not removed. Some types of plaster are slightly more expensive than other domestic counterparts, although they benefit in price compared to foreign brands.

to contents ↑Price and packaging

On sale you can find different packaging materials - 5, 15, 25, 30 kg. Some plasters are available in packs of 10 and 20 kg. For a 10-pound package you will have to pay an average of 250-270 rubles.

to contents ↑Terms and conditions of storage

Packs with dry plaster should be stored only in dry rooms, where contact with moisture is excluded, laying them on strong wooden pallets. Packaging, the integrity of which is broken, it is advisable to immediately apply for work. You can also pour the mixture into a durable bag and tie it tight. The shelf life of Volma plaster is 12 months.

Despite the huge selection of building and finishing materials on the modern market, many people choose the Volma brand because it has long earned the respect of professionals. The funds of this company are high-quality and wear-resistant, so it is quite reasonable to give their preference to them.