Stucco for walls is used for different purposes. It is able to level the surface, even repair serious defects or provide a more attractive, decorative look. To increase the strength of the plaster layer, craftsmen often use a plaster mesh - a reinforcing material for exterior and interior use.

- Grid Functions

- Types and types of grids

- Metal grid

- Woven metal

- Chain-link

- Welded

- Masonry

- Plastering metal

- Plastic mesh

- Advantages and disadvantages of plastic nets

- The use of plastic mesh

- Fiberglass mesh

- Classification and marking of fiberglass reinforcing nets

- Appointment of fiberglass mesh

- The best grid for plastering walls

- For interior work

- For outdoor work

- Do you need a grid for plastered walls

- Fixing the mesh with the right technology

- Reinforcing mesh fastening

- How to fix the product under a gypsum base

- Polymer coating

- Metal coatings

- Is it possible to glue wallpaper on plastered walls under a grid

Grid Functions

Plaster reinforcement is a popular, effective, time-tested manipulation that significantly improves the technical characteristics of the finished coating. Without reinforcement, there is a high risk of the solution peeling off the wall surface, especially if it is applied with a sufficiently thick layer. If the clutch with the plaster is rather reliable when facing concrete substrates, then when working with brick and wooden surfaces it is almost impossible to get a monolithic slab without reinforcement.

Grid for plaster, which serves as a reinforcing canvas, performs the following functions:

- It makes it possible to level the walls with a more massive layer. This is often required when there are significant differences in the base or when using beacons.

- Ensures the integrity of the plaster layer, eliminates the risk of cracking even under high loads, vibration.

- It strengthens complex areas that are prone to caving in, crumbling over windows, doors, corners and other places that do not have support under the leveling layer.

- Increases the bearing capacity of plaster. The reinforcing mesh allows you to fasten shelves, cornices, decor without increasing the risk of detachment of the coating.

- Extends the life of the coating. Draft and decorative wall decoration after reinforcement will last an order of magnitude longer.

to contents ↑Professionals advise in any case to use reinforcement, if the plaster is applied with a layer of more than 2-3 cm - this will help to avoid its separation. The scope of reinforcing paintings is not limited to internal works: they are also used to strengthen foundations, socles, floors in the attic, between floors and for other purposes.

Types and types of grids

More recently, plaster reinforcement was carried out using wood shingles. This process also increased the adhesion of the solution to the base and reduced the likelihood of collapse of the coating. Modern industry produces more convenient, light and durable materials based on plastic, fiberglass and metal.They have excellent technical and operational characteristics, unlike shingles, which are prone to damage by microorganisms and moisture.

to contents ↑Metal grid

Reinforcement with metal is a process that will strengthen not only the layer of plaster, but also the wall itself. A metal mesh often serves as a facade, suitable for other outdoor works in concrete, reinforced concrete, aerated concrete, brick. For different surfaces, different types of metal canvases are used, which differ in cell size, thickness, method of fastening rods, and relief height.

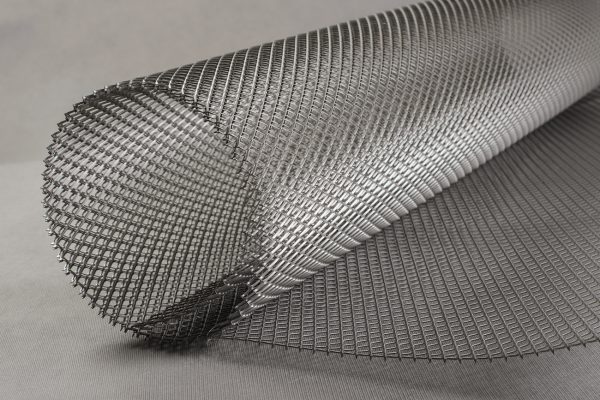

Woven metal

Such a grid resembles a fabric in structure, but instead of threads, a metal wire made of galvanized steel, stainless steel or carbon steel is used here. The material cells are small (usually 1–2 mm). It is good if the metal wire has corrosion protection. Zinc or polymer coated materials have proven themselves best. On sale there are nets with this type of weaving "threads":

- linen - 1 x 1 mm;

- twill - 1 x 2 mm, 2 x 2 mm.

The thickness of the wire can also be different, and on this basis, all the nets are divided into heavy, medium and light.

to contents ↑Chain-link

The chain-link is the most demanded type from all metal grids. It is named after Karl Rabitz, who is considered its creator. The material was first introduced to the market in 1878. It is a woven fabric with large cells of high-alloy, carbon or galvanized wire, or of metal with a polymer coating. The chain-link creates a durable embossed reinforcing frame that can hold even a thick layer of finish.

Modern types of chain-links with anti-corrosion protection are considered the most durable, not subject to external influences, so they can be used for any type of outdoor work. Often fences are created from the netting, so it is made in a wide range of colors. The thickness of the wire in the chain-link is 1-3 mm, and it is first twisted in a spiral in pairs, and only then becomes the basis for weaving a roll.

to contents ↑Welded

This building material got its name because of the production method. The cells here are formed due to the spot welding of perpendicularly arranged wires. The raw material for creating a welded mesh is a low-carbon steel wire, less commonly galvanized or PVC-coated wire.

The shape of the cells in the welded panel may be square or rectangular. The material is presented on the market in rolls 10–30 meters long and 1–2 meters high. The strength of the welded mesh depends on the diameter of the wire and the size of the cell: the thicker the wire and the smaller the cell, the stronger the material. Welded “canvas” is used to strengthen the masonry, in various installation works, to strengthen the bearing walls, the foundation. It is also suitable for the following tasks:

- reinforcing insulation, floors;

- strengthening plaster;

- manufacturing partitions, fences.

to contents ↑For plastering work, it is worth buying a galvanized wire mesh, although ordinary carbon steel material is suitable for plastering the foundation. It is also suitable for stone, concrete, wooden walls, successfully replacing shingles.

Masonry

This is another popular version of the metal reinforcing material. It is used to strengthen plaster, pour screed, strengthen walls. Masonry mesh is made by welding perpendicularly folded wire of different diameters. Like welded panels, masonry is produced in rolls of a certain length and can have a width of 1-2 meters.

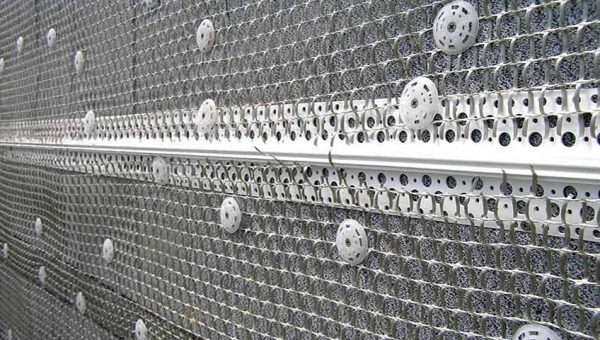

Plastering metal

This mesh is designed specifically for plastering. It is made of galvanized heat-treated wire, has small cells and a small relief.The material allows you to evenly distribute and retain the solution and reduce its loss. Due to the use of galvanizing technology, corrosion on the plaster mesh is not terrible, therefore, the appearance of rust stains on the finish is excluded.

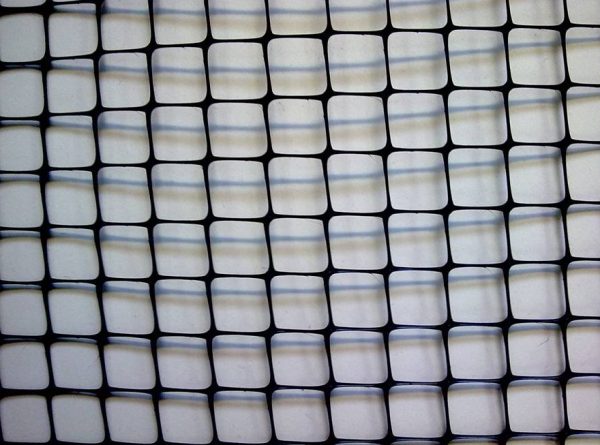

Plastic mesh

Plastic (masonry) cloth is made from modern polymers, which are characterized by the highest strength. Its thickness can be different, as well as the shape of the cells: diamond-shaped, square. The most popular option is matter with 5 x 5 cm cells. Less commonly, products with 10 x 10 mm cells are used to strengthen the outer walls.

Advantages and disadvantages of plastic nets

Plastic mesh has excellent performance. It is suitable for outdoor and indoor use, therefore it is considered universal. Other positive qualities of the material:

- high degree of moisture resistance;

- non-susceptibility to corrosion, decay;

- resistance to temperature extremes, freezing and defrosting;

- hypoallergenicity, environmental friendliness;

- resistance to vibration, mechanical stress due to elasticity and strength.

A big plus is the lack of need for fixing the grid with fasteners - it can simply be glued to the solution layer. This speeds up the work of the master and reliably reinforces the plaster. The price of a plastic sheet is lower than a metal one, which is also a significant advantage.

to contents ↑Material flaws also exist. He is able to reinforce a small layer of plaster - up to 8-10 mm, otherwise there will be a risk of detachment. Plastic is not resistant to alkaline plaster solutions, which can dissolve it over time.

The use of plastic mesh

Often, panels are used to increase adhesion between finishing materials and insulation, for example, when attaching foam. In the presence of such a reinforcing pad, you can not be afraid of the appearance of cracks on the plaster or its peeling. Also, with the help of material, you can equip the foundation, however, it is worth choosing paintings with the thickest rods. They are laid between the layers of the foundation, and on unstable soils - on a pillow of gravel and sand.

to contents ↑Another option for using plastic mesh in finishing work is to reinforce joints between sheets of drywall. For this purpose they acquire “canvases” in the form of narrow stripes or independently cut the material.

Fiberglass mesh

Reinforcing fiberglass, or fiberglass mesh surpasses plastic in its characteristics. It is an order of magnitude stronger, withstands high tensile loads, resistant to mechanical and chemical factors.

The exact parameters of the material depend on the density of its surface, measured in grams per square meter. The higher this indicator, the stronger the grid will be. Some varieties of paintings are impregnated with polyacrylic dispersion, and then they are obtained as resistant to the action of an alkaline environment. Fiberglass mesh is implemented in the form of rolls 1 m wide, as well as in the form of ribbons, rectangles, corners.

to contents ↑

Classification and marking of fiberglass reinforcing nets

Depending on the density, all panels are divided into the following groups:

- 50-160 g / sq. m. Suitable for indoor use. They are plastering and painting (the latter have the lowest density). The cell sizes are 2 x 2, 3 x 3, 2.5 x 2.5 mm or more.

- 160–220 g / sq. m. They are used for plastering, puttying on facades and other external structures. The most popular tapes have 5 x 5 mm and 10 x 10 mm cells.

- 220-300 g / sq. m. Suitable for strengthening the basement, the underground part of the building. Withstand high loads, can be used even in extreme conditions. Their cost is much higher than others.

The density of the nets and their purpose is usually expressed by special marking:

- SS - fiberglass;

- N - for outdoor work;

- B - for internal work;

- A - basement and anti-vandal;

- U - reinforced;

- Sh - putty.

Appointment of fiberglass mesh

Most often, the material is used to strengthen the internal plaster layer in order to create a durable frame that will not allow the finish to peel off, crack, peel off. Reinforcing fabric will increase the adhesion of the finishing layer to the wall due to the relief. For example, plaster tends to slide from polystyrene, silicate brick, and applying a mesh will prevent such consequences.

Also, with the help of fiberglass, it is possible to level any surface, repair seams and joints between sheet materials, panels and blocks, and strengthen the area above windows and doors. Fiberglass reinforced floors, insulation and waterproofing.

The best grid for plastering walls

The choice of material is made taking into account some rules and recommendations:

- if the layer of plaster is up to 3 cm, fiberglass is used, from 3 cm - only metal;

- for outdoor use mainly metal sheets with galvanization or polymer coating;

- plastic reinforcement is ideally suited for gypsum mortars; plastic or fiberglass is ideal for joints of gypsum fiber reinforced concrete and joints of small cracks;

- a chain-link is suitable for strengthening stove and fireplace masonry, and in the presence of a thin plaster finish - fiberglass.

If the choice is made in favor of a metal sheet, it is worth clarifying the brand of metal or alloy, its quality, as well as the method of connecting the wire. The welded method is considered more reliable than ordinary twisting. Material will be cheaper if it is produced by a large enterprise, since mass production is more than worthwhile.

to contents ↑For interior work

Typically, for decoration, use these types of paintings:

- Plastic - for gypsum and other finely dispersed plasters. It is best to choose a material with a cell of 1 x 1 mm or 2 x 2 mm, which will withstand a layer of mortar and will not allow cracks to form.

- Fiberglass - for plastering rough foundations of brick, concrete. Reinforced cement plasters, reduce the risk of sitting the mortar.

For outdoor work

For street use, you need to choose a grid with extreme care. The choice depends on such factors:

- type of plaster and its thickness;

- features of climate, humidity, temperature differences;

- size of the plastered surface.

For small substrates, fiberglass is usually used, which ideally strengthens facade surfaces and socles. A metal mesh is most often bought in such cases:

- significant surface area;

- wooden, aerated concrete or brick walls;

- high humidity, regular temperature changes;

- applying cement plaster;

- the need for increased building strength.

Do you need a grid for plastered walls

Without applying a reinforcing sheet, there is a risk of detaching the plaster from the rough foundation. The thicker the plaster layer, the higher the danger. The mesh fixing leads to the formation of a monolith, on which cracks will not appear even under the condition of strong vibration, mechanical or thermal influence. The mesh reduces the negative effects of applying a low-quality (too thin or too thick) solution, and prevents it from dripping or shedding.

Fixing the mesh with the right technology

First you need to calculate the amount of canvas that will be required to complete the work. The mounting method will depend on the type of base and the material itself. In any case, the cellular panel must be fixed strictly according to the technology, avoiding strong tension or sagging.

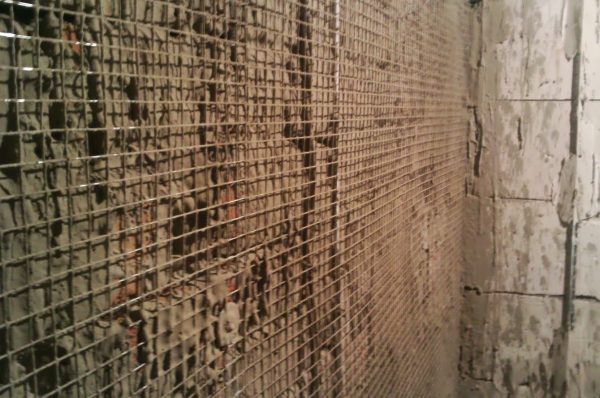

Reinforcing mesh fastening

If light products are easily fixed on the solution, rubbing with a spatula, then thicker, stronger materials need to be fixed more securely.The procedure will be as follows:

- measure the required amount of material, carefully cut a suitable piece;

- fix it with a dowel-nails at the top, smooth the corners and fix with screws;

- repeat a similar operation from below, ensuring the optimal degree of tension;

- at the end of the work, attach the matter in the middle so that it fits well on the rough base.

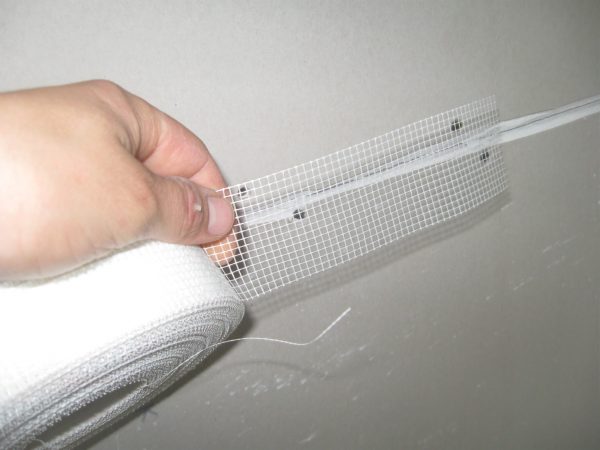

How to fix the product under a gypsum base

Colored and other decorative paintings are fixed with simple screws. Initially, they are not completely screwed into the base at equal intervals according to the markup. After they put on the net and screw the screws into the wall to the end. Sagging of the sheet should be completely eliminated! Small pieces of material or temporary coatings can be attached to the mounting foam.

Polymer coating

Typically, such canvases are fixed with a mortar and a spatula. Cut the mesh into pieces of the right size, taking into account allowances for the seams. A layer of plaster is applied, a piece of material is gently pressed into it, ironed with a spatula. The canvas is lapped, so that one strip of 15-20 cm comes into another. If the walls have a complex configuration, they additionally strengthen the fastening with brackets, self-tapping screws or dowels.

Metal coatings

For a layer of plaster equal to 3-5 cm, a metal mesh is usually used. It weighs quite a lot, therefore, is subject to reliable fastening. Before starting work, the blade is degreased to remove dirt and grease. Traces of rust on carbon steel are treated with an anti-corrosion compound. Cut the pieces of the desired size depending on the method of placement (across or along) using metal scissors or grinders.

In the construction, holes with a diameter of 6 mm and a depth of 3 mm more than the length of the dowels are drilled with a puncher. The approximate distance between the holes is made equal to 25 cm. Fix the grid on the wall with an overlap, starting from the top corner, the edges are fixed with new dowels. The material is not too tight, so that after plastering it can take an optimal position. After applying the plaster in several stages with intermediate drying of the layers.

Is it possible to glue wallpaper on plastered walls under a grid

Reinforcing material gives increased strength to the base. It does not sag, does not allow the plaster to move away from the wall, makes it possible to withstand any weight of decorative finishes. Therefore, after its application, you can stick even the heaviest wallpaper, as well as other facing materials. Plaster mesh is an ideal way to make repairs durable, high-quality and beautiful, which is why it is so popular among professionals.