Oriented particle board, or OSB (OSB), is a popular material for frame construction and interior cladding of buildings. It is lightweight, durable, safe for human health. Beginners are wondering if it is possible to plaster OSB and whether there is a need for it.

- Can OSB plaster be covered with plaster

- Difficulties in plastering OSB

- Why do you need to plaster panels

- What can be used

- Polymer Compounds

- Decorative plasters

- Mineral plaster

- Elastic plaster

- Options for plastering OSB-boards

- The traditional way of plastering

- Stucco with insulation

- Using Drywall

- Features of plastering indoors and outdoors

- Tools for work and plastering

- Preparing OSB for plaster

- Insulation mount

- Upholstery Mount

Without finishing, the sheets look unpresentable, and also require protection from external influences, therefore, in many cases they are subject to plastering.

Can OSB plaster be covered with plaster

OSB plastering is a popular type of exterior facing for oriented particle boards. Without a protective layer, this wood-based material can swell from moisture, darken, and delaminate. As a result, its service life will decrease significantly.

Plastering will help to eliminate such risks, since it will give the following properties:

- moisture resistance;

- mechanical strength;

- tolerance of temperature differences;

- vapor permeability;

- fire safety;

- resistance to UV radiation.

Plaster is a really suitable material for finishing OSB, after which you can use any finishing coat. For interior work, paint, wallpaper, tile or stone are most often used as decor. Outside the buildings, OSB boards are sheathed with siding or plastered.

The cost of finishing with plaster will be low, and the applied layer will not cause structural overload. After the work, the facade or the inner wall will look more attractive, and the operating and maintenance conditions will remain comfortable.

to contents ↑

Difficulties in plastering OSB

OSB panels are great for different types of work. Nevertheless, there are limitations in their use, because this material consists of wood, therefore it absorbs water well. If plaster with a high moisture content is applied directly to the slab, the coating will dry out and crack. The crumbling and detaching of the plaster is also facilitated by changes in humidity and temperature in the room.

Among other things, OSB can start to “play” due to contact with moisture, as a result of which cracks will go through the material itself, and its service life will decrease. Low adhesion of OSB with stucco can also become a problem, because the slab is smooth and not rough. The difficulties encountered can be addressed in different ways. For this, special plastering techniques are used, insulation, plasterboard sheets are used - it all depends on the chosen technology.

to contents ↑Why do you need to plaster panels

If the OSB board used for outdoor work or inside unheated rooms is saturated with moisture, the tree will defrost in winter and swell in summer. The result will be a loss of strength, deformation, swelling of the material.

Chemicals that bind wood in OSB do not tolerate temperature drops below –30 degrees. Plastering will create a protective barrier and prevent material damage. Also, plaster coating performs the following functions:

- strengthening heat and sound insulation of the building;

- draft prevention;

- the formation of a monolithic coating without seams, defects;

- concealment of damage, pits and chips;

- giving the wall a more aesthetic appearance;

- elimination of the need to make repeated repairs for many years;

- the ability to stain and color change at the request of the owners;

- facilitates washing or dry surface care.

What can be used

There are compounds that are specifically designed for plastering OSB-boards, although they are not often found on sale. Most of the funds are considered universal and are divided according to other principles.

For example, according to the properties and specifics of the application of plaster there are:

- leveling;

- finish;

- special: noise reducing, waterproofing, etc.

Usually, finishing plasters are chosen for cladding, because the plates do not need to be leveled. Tools for plastering are implemented in finished form or require dilution with liquid. In addition, building mixtures can have a different composition: some are suitable only for street work, others for indoor, and others are used in any conditions. The difference in quality and function is provided by the base of the plaster, as well as fillers and additives.

to contents ↑Polymer Compounds

Plaster on polymer binders - a material ideal for processing OSB. They are based on synthetic resins or other polymers that provide high strength and long life.

The most popular materials in the group are:

- Silicone plaster. Very plastic, easily lays on the surface, resistant to moisture, while vapor permeable. It has antiseptic properties. It is sold in white, as well as in pigmented versions.

- Silicate plaster. Contains liquid glass, which after hardening provides the coating with particular strength. Plaster is not afraid of water, does not violate the microclimate in the room, contributes to the destruction of the fungus. The service life of the material is 30-50 years, but its price is quite high.

- Acrylic plaster. Made on the basis of acrylic resin, suitable only for interior use. It has a lower strength than other representatives of the polymer compositions. It is easily tinted or painted after solidification, it is inexpensive.

- Siloxane plaster. It is a modification of the silicone mixture, which is based on siloxane - silicone with a simplified molecule. It has a less pronounced moisture resistance than silicone, is gradually destroyed by ultraviolet radiation. The service life of such plasters is 3-5 years.

- Cement plaster. This is an improved cement-sand mixture enriched with polymers. Due to changes in the composition, the material becomes elastic, obtains greater bending strength, shrinkage, gains excellent adhesion to building materials and resistance to abrasion.

to contents ↑To process indoor OSB, you only need to buy eco-friendly water-based compounds. For facade work, plasters based on organic solvents are more suitable, the strength and moisture resistance of which will be higher.

Decorative plasters

The materials of this group are intended not only for protection, but also for creating a decorative layer on OSB-plates. They are suitable for exterior and interior use, contain various fillers in the composition. The main varieties of decorative plasters that can be used when working with oriented particle boards:

- Structural. Include impurities of quartz, small pebbles. When applied to the substrate, a rough surface can be obtained. When OSB is lined with some types of structural plasters, multicolored spots appear.

- Venetian. Contain fine marble chips.After drying, the base will resemble a stone that looks noble and very beautiful.

- Textured. They can contain a wide variety of impurities: cellulose, pebbles, mica, silk, pieces of fabric.

- Flock. They consist of three layers: base, flock (with pieces of dried acrylic) and lacquer. They are quite expensive, difficult to use.

Mineral plaster

The basis of such plasters are cement, gypsum, lime, clay. In their pure form, they are poorly suited for working with OBS, since they do not have the proper plasticity, they are afraid of impact. If you accidentally hit a wall, a whole piece of plaster may fall off the slab. If the building vibrates, the layer may also crack. Gypsum mixtures are very afraid of moisture and are not suitable for outdoor work, wet rooms. The advantages of mineral plasters are:

- vapor permeability;

- environmental friendliness;

- strength (under static loads);

- frost resistance;

- maintainability;

- durability;

- affordable price.

Elastic plaster

Like standard polymer plasters, elastic compositions are based on synthetic acrylic resins, but have an increased proportion of them in the composition. An undoubted advantage is the high elasticity of the material, its ability to stretch during deformation, vibration, displacement of the base.

Such plasters are ideally suited for new buildings, houses that are located in an earthquake-prone zone.

Positive qualities are:

- moisture resistance;

- strength;

- environmental friendliness;

- long service life;

- high adhesion to OSB;

- maintainability;

- ease of application, ductility;

- ease in leaving.

Many elastic plasters attract dust, dirt, which is their undoubted disadvantage. In addition, the cost of materials is higher than that of mineral and standard polymer compositions.

to contents ↑Options for plastering OSB-boards

Depending on the user's needs and operating conditions of OSB-plates, plastering works can be carried out by different methods.

The traditional way of plastering

This technique does not involve the use of insulation, so it is used less often. To work, you need to prepare a vapor barrier membrane, mesh for reinforcement, double-sided tape, primer, plaster and adhesive. Of the tools you will need a construction stapler, spatulas and graters, a roller.

The procedure will be as follows:

- Cut a piece of vapor barrier of the right size, fix it with a stapler to the OSB plate (at the joints they overlap by 10 cm).

- Glue the borders and seams between the plates with double-sided tape.

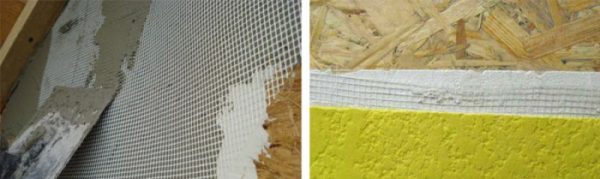

- A reinforcing mesh is put on tape.

- Mix construction adhesive according to the instructions, apply to the surface of the mesh in 1-2 layers.

- After drying, the coating is treated with a primer using a convenient roller.

- Apply plaster to the grid using trowels and leveling the layer with graters.

With this method of plastering, it is worth using elastic mixtures that do not crack from the displacements of the OSB joints. If modern vapor barrier material is not available, you can use bitumen cardboard or even a regular roofing material.

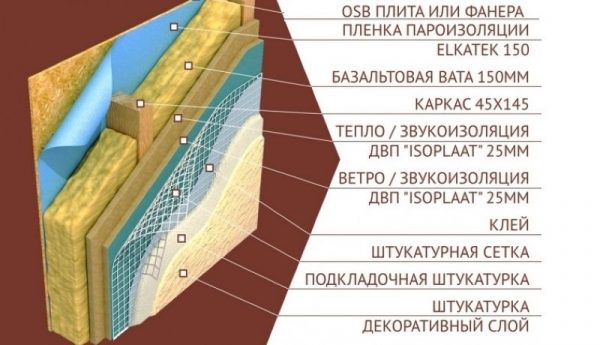

to contents ↑Stucco with insulation

As a heater, most often take a foam sheet (40 mm). This technology is suitable for processing exterior walls or interior areas in unheated rooms. The sequence of actions will be as follows:

- Sheets of insulation are glued onto the clean, primed and dried surface of the OSB boards.

- After drying the adhesive in the center and corners, the foam is fixed with dowels, well deepening the hats.

- In order to avoid the formation of “cold bridges”, the joints of the foam sheets are closed with foam, after drying it is cut off.

- Apply building glue (3 mm layer), reinforcing fiberglass mesh is laid on top, recessing it into the composition with a spatula.

- The exposed glue is leveled with a spatula.

- As it dries, the adhesive layer is plastered.

to contents ↑It is highly undesirable to work with plaster if the temperature outside is outside + 5 ... + 35 degrees, and the weather is windy or damp.Indoors, you should adhere to the same temperature limit, as well as humidity not more than 65%.

Using Drywall

Typically, the combination of OSB + drywall is used to insulate buildings and to seriously reduce noise. Initially, the oriented strand board is fixed with self-tapping screws on the guides, then the drywall sheets are installed with new self-tapping screws on the same guides. Another option is to stick GCR to OSB, and then fix the structure with screws.

Joints of materials should not coincide, otherwise it will contribute to the appearance of “cold bridges”. After completion of the fixing work, the drywall is puttyed with suitable building mixtures. In humid rooms under GKL, vapor barrier is laid, in dry rooms this stage can be skipped.

to contents ↑Features of plastering indoors and outdoors

In general, the technology for working with OSB boards outside and inside buildings is the same, although there are some differences. When choosing plaster, the type of work must be taken into account: for outdoor use, you should buy frost-resistant material with increased moisture resistance, UV resistance.

Facade plastering work is carried out only on a dry, windless day. In case of unexpected precipitation, the wall is securely covered with polyethylene. When the temperature rises above +35 degrees, the work is stopped.

Indoor working conditions are more comfortable. The main thing is to ensure the absence of drafts and normal humidity.

to contents ↑When applying plaster to OSB in the house, fans, heaters, heat guns cannot be used for drying: this will lead to cracks. Before starting plastering, it is important to completely de-energize the wiring.

Tools for work and plastering

In order to qualitatively fulfill all the tasks, you need to prepare a list of materials and consumables in advance:

- container for mixing the plaster (if it is a dry mixture for dilution with water);

- spatulas of different sizes;

- trowel, grater, grater;

- short-brushed brush and roller;

- primer;

- glue;

- masking tape;

- sealant;

- stapler with staples;

- grinding machine;

- solvent;

- drill with mixer nozzle;

- rags;

- construction level.

to contents ↑

Preparing OSB for plaster

If a lot of time has passed after fixing the OSB, the surface of the plates may become covered with dust, dirt, stains. The material must be thoroughly cleaned, because otherwise adhesion with the plaster will decrease. It is best to wipe the surface with white spirit or other solvent so as not to wet it with water. In the room, you can clean the walls with a vacuum cleaner, and selectively wipe the spots with acetone.

Next, the joints between the plates are sealed with a sealant, choosing a composition with increased elasticity (acrylic or silicone). It is highly elastic compounds that will allow you to save compensation gaps on the sides. If there are bumps, scars, or other defects on the plates, they are removed using a grinding machine or sandpaper. After brushing or applying acrylic primer in 2 layers with complete intermediate drying. Instead of such a primer, you can use a primer with fine quartz chips, which improves adhesion.

to contents ↑Insulation mount

Mineral wool can be used instead of polystyrene to arrange insulation outside the premises. After attaching the roll insulation and gluing the reinforcing mesh, priming is carried out, and then plastering the base.

For internal work, mainly polystyrene foam is used, which is glued directly to a suitable adhesive in this way:

- The surface of the OSB is degreased, the dirt is removed.

- The adhesive is applied with a spatula.

- Reliably press the insulation to the glue.

- Wait for the glue to dry.

- The joints are reinforced with a tape with a self-adhesive base.

Upholstery Mount

This stage involves the lubrication of the joints between the sheets of insulation with a sealant, as well as the laying of cardboard impregnated with bitumen, kraft paper and fixing them with brackets. For the purpose of additional insulation, these materials can be used as an addition to a traditional insulation or instead of it as a more economical option.

The final plaster layer is applied with spatulas of the right size. If decorative plaster is used, a surface is formed according to the selected effect. The dried layer is stained or varnished. Working with OSB-plates is simple, but requires care, following the technology and accuracy at each stage.