Marble plaster is often used in decorating. It is suitable for cladding internal and external walls, helping to level surfaces, hide all defects and seams. The material is available in a wide range, which facilitates the selection.

- Features of marble coating

- Composition and characteristics

- Scope of application

- Types of material

- The color scheme of the marble mixture

- Advantages and disadvantages

- The technology of applying marble plaster

- Preparatory stage

- Manual plastering

- Mechanically applying plaster

- Create a drawing

- Application on the facade

- Drawing decorative material indoors

- Material quantity calculation

- Colored modulations of marble plaster

- DIY marble plaster

Features of marble coating

Marble stucco was used by man back in ancient Egypt and Rome. It was prepared from strong, reliable materials, so the created coating had unique properties and aesthetic characteristics. Now the basis of the plaster are acrylic or mineral polymers, which are complemented by stone chips.

Depending on the specific need, you can choose a material with the following properties:

- moisture resistance;

- antibacterial effect;

- plastic;

- increased resistance to mechanical damage.

The most popular decorative marble plaster is manufactured by Bayramix. It was this manufacturer who first introduced the material on the modern market, therefore it is considered the founder of the "stone fashion" in the interior. Also on sale you can find products of the company "Granulum", which produces only environmentally friendly, high strength, flexible, breathable coatings for interior work and for the facade.

to contents ↑Composition and characteristics

Acrylic resins are transparent or translucent in appearance. The plaster, which is made on a mineral basis, looks matte - white or colored. Most often, ground marble or granite of different granularity of a rounded shape acts as a filler for it.

Since the granules themselves are painted in various shades, the finished plaster has a rich color palette. Nevertheless, to increase the decorativeness, the agents are tinted with pigments, spangles, nacre and other impurities are introduced into them. Also in the composition of the plaster may be present:

- antiseptics and fungicides;

- water repellent additives;

- plasticizers;

- modifiers

- adhesion promoters;

- substances for increasing color fastness;

- solvents;

- varnishes;

- waxes;

- preservatives.

It is thanks to the presence of stone chips in the composition of the plaster that the effect of marble and a certain roughness are achieved. To reduce the cost, part of the marble component is replaced with granite, while the quality of the plaster is practically not reduced. Moreover, it is possible to enhance the strength properties of the coating, because granite is more strong and wear-resistant than marble.

to contents ↑Scope of application

Marble plaster is perfect for facing substrates that need increased protection against water - plinths, facades, foundations. Also, with its help, bathrooms, pools, saunas, baths are finished.The material is ductile and is easily applied to products and surfaces with bends, therefore it is suitable for niches, columns, bay windows, ledges, as well as arches, openings, and any architectural forms.

Stucco with stone chips is widely used indoors. Especially popular is this type of coating in cottages, houses with a classic, antique style. Nevertheless, marble plasters also fit into modern style trends, allowing you to create fashionable details, patterns, highlight walls or separate stripes, sections. As for the base materials, stucco with marble chips perfectly fits on the surface, not prone to shrinkage:

- brickwork;

- concrete, cement;

- foam blocks;

- cinder blocks;

- OSB, chipboard;

- drywall;

- plastered walls.

Types of material

Marble plaster is conventionally divided into two large groups:

- Marble. Includes natural stone chips.

- Venetian. Its basis is marble or granite flour with the addition of special pigments imitating crumbs.

Most often, the stucco filler has a spherical shape, less often a faceted one. Depending on the basis of the material is calcareous, acrylic and sand-cement. According to the size of the granules, marble plaster is classified as follows:

- Fine-grained. Grain size is 0.5 mm or less.

- Medium grained. The grain diameter is 1-3 mm.

- Coarse-grained. It includes a fraction of up to 3-5 mm.

Typically, for interior work they buy marble material with small and medium grit, and for facades - with large.

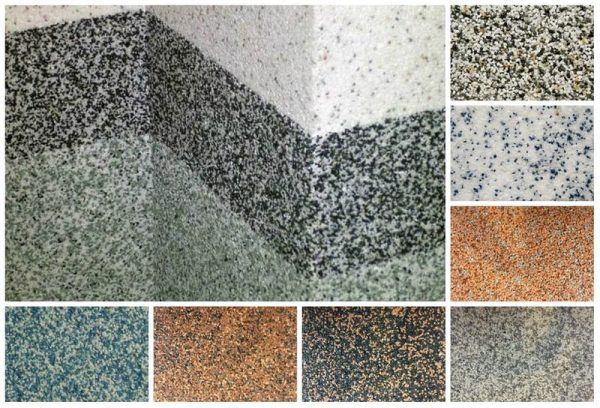

to contents ↑The color scheme of the marble mixture

A large assortment of marble plaster is available on the market. Until recently, its colors were limited to the natural color of the stone, but now they are determined by a variety of synthetic pigments. So, the company "Granulum" in the catalog indicated 48 basic shades that can be mixed with each other and get new tones. High-quality plaster 100% preserves the naturalness of the paint for 15 years on the facades and about 25 years for internal use.

to contents ↑Advantages and disadvantages

Marble plaster has many advantages:

- withstands even serious mechanical stress, is not damaged, is considered very wear-resistant;

- has a long service life due to excellent strength characteristics;

- resistant to ultraviolet radiation, atmospheric factors, temperature extremes;

- does not violate the microclimate in the house due to vapor permeability;

- does not allow moisture to accumulate on the walls;

- environmentally friendly, does not contain toxic components, has no smell, does not emit harmful substances even at elevated temperatures;

- easy to mount on the surface, including complex in shape;

- universal: can be used indoors and outdoors;

- has increased moisture resistance;

- different fire safety, does not support combustion, smoke;

- after drying, easy to care for, it can be washed with any household means;

- does not allow mold and fungi to multiply.

The disadvantages include the high cost of the material, so not everyone can afford to finish the facade or premises with marble plaster. Over time (after 15-25 years), the finish will lose its brightness, although it can be painted in any suitable color. Plaster is vulnerable to aggressive chemicals (for example, hydrochloric acid), although such contact in everyday life is difficult to imagine.

to contents ↑The technology of applying marble plaster

In order not to be distracted during the search for the right tools, it is better to prepare in advance what may be required:

- two stainless steel spatulas - narrow and wide;

- trowel - a steel blade for masonry and grinding;

- a trowel for leveling the solution, a grater for mashing;

- containers for mixing or applying plaster;

- a drill with a mixer nozzle (only needed to prepare a dry mix, but you will not need a ready-made plaster);

- level - will help determine the evenness of the applied layer.

to contents ↑

Preparatory stage

The base to be plastered must be carefully prepared. It is cleaned of dirt, dust, carefully inspected. All swellings, delaminations, crumbling sections are cleaned to a hard surface with a spatula. In difficult cases, you may need a grinder, a metal brush, a grinder.

If places affected by mold are revealed, they are well moistened with antiseptic compounds 2-3 times. The efflorescence from the wall is cleaned with special cleaners, which are sold in construction stores.

All cracks, chips, pits are sealed with a standard solution of 1 part cement and 3 parts sand. Before coating, they are slightly embroidered, cleaned of dust. Large pits are filled with pre-laying reinforcing fiberglass mesh. After that, check the surface condition with a level and, if necessary, plaster the entire base, leveling it.

Useful tips for the master at the preparation stage:

- Coarse-grained mixtures are best applied to the rough leveling layer, and fine-grained - only on the finishing (finishing) after preliminary grinding.

- As the walls level out, it is imperative that they be primed with covering primers, if necessary tinted in the color of marble plaster.

- Let the primer dry for 12 hours or more.

to contents ↑It is necessary to acquire marble material with a margin of 7-10%, since part of it crumbles during application and remains on the tools. It is important that the entire plaster is from the same batch, since even from the same manufacturer different deliveries may vary in color.

Manual plastering

First, a dry mixture is diluted according to the instructions or the finished composition is mixed well. If it is too viscous, thick, add a little water, 50-100 ml each (too much liquid can ruin the material).

Further work in this way:

- Gather a little money on a small spatula, put on a large spatula or trowel.

- Apply the solution to the surface, holding the tool at an angle of 60 degrees.

- Distribute the mass in a uniform layer, moving in one direction and applying a certain force (you can use a half-trick).

- If you have to interrupt the work, a strip of masking tape is pasted along the border of the future joint, and after the start of a new stage, the tape is removed.

After 30 minutes, when the marble plaster begins to set, proceed to mashing. Take a stainless steel grater, firmly lean against the wall, smooth the coating in a circular motion. Strong pressure or long processing of the same area is not necessary. After complete drying (in a day), the wall is irrigated with a hydrophobizing agent or acrylic varnish from a spray gun and left to dry for another 12 hours.

to contents ↑Mechanically applying plaster

To perform all the work faster, use a different method of applying plaster. It is used by professionals, especially when it comes to processing a large area. You need to buy or rent a pneumatic crusher - a container with a nozzle (hole diameter - 4-6 mm) connected to the compressor.

After preparing the base, the solution is poured into the crusher, the compressor is turned on with a pressure of 6–7 atmospheres, and air is pumped. When applying the composition, the nozzle is kept at a distance of 50 cm from the base, moving it from top to bottom. Make sure that the product evenly covers the wall without the appearance of bare patches. After 30 minutes, the plaster is wiped in the same way, and after a day it is treated with a protective compound.

to contents ↑Create a drawing

For a more decorative wall, facade, you can use marble plaster of several colors to create patterns, patterns, ornaments. First draw a sketch on paper, then make markings on the wall.Masking tape is glued around the perimeter of individual sections, then plaster of the selected color is applied. After mashing the adhesive tape is removed, stick new strips in the following areas. Thus, you can make any drawings, inserts of the desired size and shade.

to contents ↑Application on the facade

Street decoration is regularly exposed to adverse factors: temperature extremes, precipitation, sunlight. For facade cladding, special plaster is used with increased strength characteristics and large grain. Work with it only in the dry warm time, taking into account the following recommendations:

- The brickwork is preliminarily prepared: the solution protruding from the joints is cleaned, the wall is plastered, and it is dried well.

- Penetrating acrylic primer is applied in 2-3 layers, waiting for each of them to dry, using a roller or brush.

- They work together as much as possible, so that in one pass put plaster immediately on the entire wall and rub it.

- For wall cladding, you can use a pneumatic crusher, holding the nozzle tip at a distance of 50 cm from the surface.

- After drying the plaster, it is completely wiped with a steel grater, a protective varnish coating is applied.

to contents ↑

Drawing decorative material indoors

In the house, apartment should use a fine-grained or medium-grained mixture. The decorative layer should be thin - not more than 1–1.5 diameters of stone crumbs. Indoors provide normal humidity (up to 65%). All electrical appliances built into the walls are turned off in advance. After mashing, not wax is used, but wax, which is more suitable for interior decoration due to environmental friendliness.

to contents ↑Material quantity calculation

On each package of plaster, the manufacturer indicates the consumption per square meter. This indicator is approximate and in practice may vary depending on the quality of preparation of the base, the skill of the performer, etc. Mixes with round grains have a slightly lower consumption than those that contain grain with faces.

Also, the flow rate varies depending on the granularity index itself:

- large fractions - up to 8 kg / sq. m;

- middle fractions - 4-5 kg / sq. m;

- fine fractions - 2-3 kg / sq. m

to contents ↑On average, the thickness of the plaster layer is 5–30 mm (for outdoor work it needs to be made larger). According to the indicated data, it is possible to calculate the material consumption and purchase the required quantity with a small margin.

Colored modulations of marble plaster

If you want to make the original shade of plaster yourself, you can purchase several compositions of different colors and combine them. For example, material from red and white marble chips, as well as from white, pink and gray, looks very attractive. If you add gold or silver powder, the appearance of the finish will be unusual and luxurious.

to contents ↑DIY marble plaster

To save on decoration, you can make marble plaster with your own hands. To do this, you need to get a binder component, filler (marble or granite chips), as well as pigments. White cement M500, acrylic putty can act as a bond. Using a mixer, 1 part of the binder, 3 parts of the filler are combined and dye is added, as well as 1 part of water. Finished plaster should have a very thick sour cream texture.

For another recipe for preparing plaster, you need to combine:

- 1100 ml of slaked lime;

- 1100 ml of marble chips;

- 30 g of liquid soap;

- 360 ml of linseed oil;

- 180 ml of water;

- pigment.

After mixing the components, the plaster is obtained, the quality is almost no different from the store. Depending on the size of the grain, it can be used for outdoor or indoor use. Marble plaster is a beautiful and elegant material that is durable and practical.It is easy to apply on your own, taking into account the above tips.