Drywall is used to solve various problems in the arrangement of premises. It allows you to perfectly align the walls and ceilings, form partitions, niches. For beginners in the construction business, gypsum plasterboard is surprising. It is worthwhile to understand the question of whether it is necessary to plaster the material, why it is required, what means are suitable for work.

- Drywall Features

- Why plasterboard is needed

- Stucco and putty - what is the difference

- Types of Drywall

- Plaster selection

- Gypsum plaster

- Cement plaster

- Modern polymer compositions

- Tools and consumables for work

- Features of the preparatory work

- Drywall plastering technology

- For painting

- Under the wallpaper

- Is it possible to apply decorative plaster on gypsum plasterboard

- Is it possible to plaster gypsum plasterboard "Rotband"

- Tips & Tricks

Drywall Features

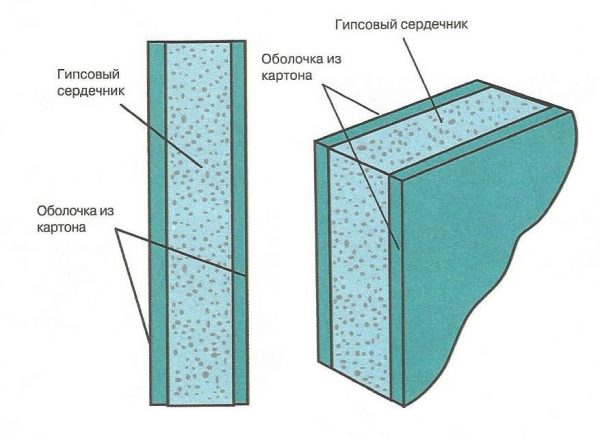

Drywall (GKL) is a building material in the form of sheets, which consist of 2 layers of construction paper and a gypsum core. Such sheets are sheathed on various surfaces, creating all kinds of designs. Drywall is attached to the walls by self-tapping screws or by gluing with suitable adhesive compounds.

In terms of strength, drywall is inferior to stone, brick, concrete, wood, so it often needs additional protection. Often, the edges of drywall sheets break, the corners break off, the screws of the screws stick out ugly. All these defects can be covered with plaster, although not every solution is suitable for GCR. Too heavy plaster deforms the sheets, too wet a mass will cause destruction, a decrease in strength. Therefore, the question of how to plaster drywall is rather complicated and requires the adoption of the right decisions.

to contents ↑Why plasterboard is needed

The paper layer of drywall does not look very attractive. It is necessarily covered with decorative materials - wallpaper, paint. But when forming walls, ceilings and partitions, it is necessary to join the sheets, and through the thin finishing materials, the seams and hats of fasteners will shine through. Therefore, before painting the walls or gluing the wallpaper, the plane of the GKL coating is smoothed with plaster.

Other situations where plastering is mandatory are as follows:

- Subsequent application of decorative plaster. To improve the quality of adhesion to the decor, conventional plastering work is first carried out.

- The need for additional protection. Plaster will help protect GCR from insects, rodents, mold, external influences.

- Filling and bending sheets. When there is no way to fix damaged structures, some problems can be solved by plastering.

to contents ↑Apply the plaster to the entire sheet of drywall or only to the seams and joints. In any case, standard plastering is possible with respect to moisture resistant material. Conventional GKL sheets will deteriorate from simple plaster, since it contains water. Only a building mixture that does not release moisture is suitable for them.

Stucco and putty - what is the difference

These materials have a general purpose - both of them are used to level various surfaces.Nevertheless, the difference between plaster and putty is great:

- plaster allows to smooth out significant irregularities of walls, ceilings, and putty eliminates only small defects;

- the plaster is distinguished by the content of large particles, therefore it is used for rougher alignment, in putty the grain size is very small, it lays in a thin layer;

- plaster is needed for rough leveling, and putty is for finishing (although fine-grained putties also allow finishing work);

- plaster is usually applied with a thicker layer than putty (in the latter layer does not exceed 1-3 mm);

- the strength of the plaster is higher than the putty, but the shrinkage is also more significant;

- the plaster can be applied immediately over a large area, and then leveled, and the putty is applied only in small portions and smoothed with a spatula.

When choosing a material for GKL finishing, these features should be taken into account in order to choose a really suitable tool.

to contents ↑Types of Drywall

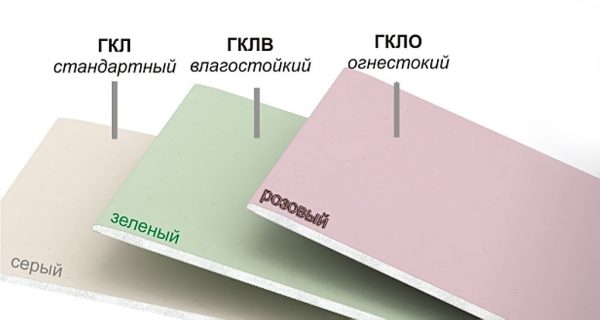

Depending on the composition of the core, properties and purpose of GCR, they are classified as follows:

- Wall drywall. It is a standard material based on gypsum. It is produced in two versions: regular and ceiling. The latter is characterized by reduced thickness and reduced weight.

- Moisture resistant GKL. Lined with green cardboard, usually used in bathrooms or where it is supposed to be putty. It is processed with special impregnations, as well as antiseptics, therefore it is not afraid of moisture, fungus and mold.

- GKLO. Flame retardant with reinforcing and fiber components. Suitable even for facing fireplaces, chimneys. In direct contact with fire, only the paper part is charred.

- Flexible arched drywall. The core of the material contains fiberglass, which bends in any direction with a radius of up to 30 cm. It has a small thickness and a high price.

- Moisture-resistant GKL. It is characterized by the properties of moisture-proof and fire-resistant drywall.

- Combined material. Designed for wall insulation, contains a layer of expanded polystyrene.

Plaster selection

Drywall can be plastered with different materials, which are not the same in composition and properties. For wall and ceiling GCR, it is allowed to use only those solutions that do not contain water or include its minimum amount. Polymer compositions are suitable for all sheets, and cement compositions are suitable only for moisture resistant ones.

Gypsum plaster

The material is used in dry rooms because it contains gypsum, which does not tolerate moisture. Gypsum-based plaster is well suited for GKL sheets, as it has a similar composition, quickly sets and hardens. The advantages of the gypsum mixture are as follows:

- vapor permeability, no effect on the microclimate;

- environmental friendliness and fire safety;

- light weight, versatility;

- ease of kneading, application, restoration of damaged areas;

- minimal shrinkage, no cracks;

- low consumption.

to contents ↑In addition to hydrophobia, gypsum plaster has other disadvantages - reduced frost resistance, too quick solidification of the solution, the inability to start the mass in large portions immediately.

Cement plaster

The main component of such a building mixture is Portland cement. As additives are sand, plasticizers, various additives. Most cement plasters are considered frost resistant, so they can be used for outdoor applications. They quickly and firmly adhere to the base, are easily divorced and applied, durable, resistant to moisture. With the help of cement mixtures, you can give moisture-proof drywall additional protection against water.

The disadvantages of such plasters are:

- heavy weight, unsuitable for thin sheets of gypsum plaster;

- a long set of final strength;

- poor vibration tolerance.

Modern polymer compositions

Polymer plasters are an invention of recent years. They may have a gypsum or cement base, but their properties are still determined by the added polymer materials:

- acrylic;

- silicone;

- siloxane, etc.

Such building mixtures easily withstand high humidity, are elastic and do not shrink, quickly gain strength and do not deteriorate from mechanical stress, vibration. They are suitable for any room, as well as for outdoor work.

to contents ↑The weight of such mixtures is small, so they do not burden the plasterboard wall. By cons include the high price of such products. In addition, they are sold in diluted form in small packages, which is not always convenient.

Tools and consumables for work

Work with plaster and GKL sheets is done using special tools. You should prepare them in advance on the following list:

- construction mixer or drill with the appropriate nozzle;

- metal and rubber spatulas of different sizes;

- reinforcing mesh (canvas) to strengthen structures;

- fine grit sandpaper;

- masking tape and stationery knife;

- a bucket or other container, water, rags;

- screwdriver or screwdriver.

For priming the walls, brushes and rollers may be required, for leveling the plaster - usually a grater.

to contents ↑Features of the preparatory work

First, you need to level the surface of the gypsum board and seal the fasteners. By inspecting and feeling, they check if there are any self-tapping hats protruding above the sheet. If possible, they should be tightened stronger, but carefully so that cracks do not go along the sheet. You can work with a screwdriver - so all actions will be better controlled. Next, the holes are filled with plaster, applying it with a narrow spatula crosswise.

An edge is present at the joints of the material, but in some cases the manufacturer does not form it. In this situation, you have to take a sharp clerical knife and cut the ends at an angle of 45 degrees. Otherwise, the sealing of the seams will be of poor quality. GKL chips, other defects are covered with plaster or putty, necessarily reinforcing with a piece of mesh. Arches, other elements with bends are strengthened with special corners, which are external and internal.

Also, as preparatory measures, the following are taken:

- well clean GCR from dust, brushing it off with dry rags;

- primer the material with solutions that strengthen the structure;

- after a day, the state of putty defects is assessed - if shrinkage occurs, repeat the work.

Drywall plastering technology

Plastering the walls of gypsum board is usually carried out according to the technology "on the cut". Any irregularities with differences of less than 1.5 cm are treated with a wide spatula in one or two layers with obligatory intermediate drying. The applied composition is leveled by the rule, resting it on the surface of the GCR. In some cases, the curvature of the walls is more significant. Then plasterboard plastering is carried out by lighthouses. Apply material in 2 layers, after unevenness they wipe with sandpaper.

to contents ↑For painting

If you plan to finish GKL for painting, the surface must be perfectly leveled. It is possible to apply 2-3 layers of starting plaster, although they are usually limited to 1-2 layers. After drying, the surface is slightly sprayed with water and rubbed with a round grater. Finishing putty is necessarily carried out, and after drying - thorough grinding to eliminate the smallest irregularities.

to contents ↑

Under the wallpaper

Without plastering the walls of drywall under the wallpaper, there is a risk that the finish is firmly glued to the wall. If necessary, change the wallpaper, the upper layer of GCR will be ripped off with them. Under thin, paper canvases, thorough plastering is carried out, similar to what is required for painting walls.

More dense wallpapers are able to hide minor surface imperfections, therefore it is permissible to use only starting fine-grained plaster.Then the wall is overwritten, after drying, it is ground and primed. Then she will be ready for wallpapering.

Is it possible to apply decorative plaster on gypsum plasterboard

Decorative plaster - a material related to the finish. Such mixtures are widely used for plastering GCR. The most common types of plaster are:

- relief (textured) - products with a coarse-grained texture, including various fillers (mineral chips, mica, fibers, pebbles);

- structural - contain quartz or marble chips, the finished coating is almost smooth or slightly embossed;

- Venetian - in their composition there is slaked lime, marble in the form of crumbs, so the coating imitates a natural stone surface.

Before applying any decorative plaster on drywall, the entire cycle of preparatory work with priming is performed. Under thin coatings GKL is additionally coated with putty and sanded to perfect smoothness.

to contents ↑Apply the finishing material with a spatula, trowel or roller, observing the technique of creating the selected effect. The decorative layer should not be too thick. After drying, it is coated with varnish or paint.

Is it possible to plaster gypsum plasterboard "Rotband"

Gypsum plaster “Rotband” from “Knauf” is perfect for work with gypsum plaster. This is a high-quality German-made product that is suitable for dry and wet rooms, and due to its lightness - for ceilings. “Rotband” includes gypsum, polymers, fillers and plasticizers. The surface after applying such a plaster is perfectly smooth. Of the minuses, one can only name the unsuitability of the product for metal, so the caps of the screws should be well insulated in advance.

Before applying the “Rotband”, they must be treated with a deep-penetrating primer, which improves adhesion to the substrate and prevents the penetration of moisture from the plaster into the GKL sheet. For work, use a spatula with a size of 30 cm, holding it at an angle of 40 degrees. Drying "Rotband" lasts 24-48 hours, depending on the thickness of the layer.

to contents ↑Tips & Tricks

If it is decided to decorate the room with gypsum plaster sheets, it is worth acquiring moisture resistant material. It is more expensive, but much better. Even in dry rooms, unforeseen contact of the substrate with water is possible, while the integrity of the drywall is maintained. In order for the work to be performed efficiently, it is worth following the following tips:

- work at a temperature within + 5 ... + 30 degrees and humidity up to 60%;

- eliminate the appearance of drafts in the room;

- start plastering from the ceiling;

- monitor the state of the GKL joints - cut off the peeled cardboard, grind the seams with emery cloth, close up the chips;

- to seal sockets, switches with masking tape to prevent splashes;

- do not forget about applying a primer, if possible, perform at least 2 layers of soil;

- apply reinforcing tape exactly in the middle of the seam;

- dry mix only with cold water.

It is not difficult to work with drywall, and the result when following the technology is excellent. This material allows you to add evenness to the walls, create beautiful designs and make the interior modern and stylish!