When arranging a private house, many prefer to install a stove. This design is perfect for eco-style, gives the atmosphere a certain flavor, and also has a number of practical functions - it makes it possible to heat the house and cook various dishes.

- Why plaster a stove

- Features of mixtures for plastering stoves and fireplaces

- How to plaster an oven without cracks

- Clay-sand mixture

- Cement-clay-sand mixture

- Lime and clay sand plaster

- Popular ready-made mixes

- Mortar plaster mortar

- Plastering tools

- How to plaster the oven: instructions

- Reinforcement

- Splashing

- Alignment and Coating

- Grout

- Oven decoration

- Coloring and whitewashing the furnace

- Decorative plaster for stoves and fireplaces

- Tile

- Tips for plastering stoves

- Repair of stove plaster

To extend the life of the finish coating, special plaster for stoves is used. With the right choice and application of plaster, the stove will look beautiful and will remain reliably protected from damage.

Why plaster a stove

Any stove in the base has a frame made of metal, bricks or clay. Fireplaces, unlike stoves, are also made of stone or concrete. All these materials have different thermal conductivity and coefficient of thermal expansion, uneven service life, differ in aesthetic properties. If the construction on top is not covered with a layer of finishing material, it can quickly lose strength and attractiveness.

Without plastering or any other type of finish over time, masonry joints will crack. The same thing happens with the clay walls of the furnace - a grid of cracks appears on them, which will have to be regularly coated. The absence of a plaster layer leads to the penetration of smoke, soot through cracks and their subsidence on the walls of the house, furniture, which spoils the environment and pollutes the air.

Other goals for which it is recommended to use plaster for stoves:

- increasing the strength of the entire structure, its resistance to destruction;

- optimization of heat transfer and improvement of thermal insulation;

- increased safety of using the stove;

- ensuring tightness and durability of masonry;

- giving the design a neat, neat appearance or changing the design of the furnace for a new interior.

As for decorative fireplaces, their plastering is carried out primarily for aesthetic purposes. Usually used marble plaster for a fireplace, Venetian plaster or composition with the effect of "travertine". If the fireplace has an exhaust system and is really used to heat the room, modern heat-resistant plasters are used for its lining, which have a lot of advantages:

- ease of application, low consumption;

- increased fire safety, incombustibility;

- high adhesion with any materials;

- increasing the heat capacity of the fireplace, long-term preservation of heat.

Features of mixtures for plastering stoves and fireplaces

Not every building mix is suitable as a plaster for a furnace.It must comply with a number of requirements, otherwise it will quickly become worthless, since it is operated in extreme conditions. A large temperature difference is observed inside the furnace and on its surface during heating, and after cooling there is a sharp temperature difference. As a result, the plaster regularly expands and contracts, and in the absence of certain properties it begins to become cracked.

Only special heat-resistant plaster with high elasticity will not deteriorate from such operating conditions. The material should easily tolerate temperature changes, reliably adhere to the base and not crumble. It is important that the heat-resistant plaster is environmentally friendly, without the admixture of toxic components, drying oil, oil paints. When heated, harmful substances will decompose and have a negative effect on the body of residents.

How to plaster an oven without cracks

In order for the plaster coating of the furnace to serve for a long time, without shrinkage cracks, it must adequately respond to the expansion process of the furnace during heating. Of all the compositions existing on the construction market, several types of clay-based products meet this requirement. In addition to clay of a certain fat content, gypsum is suitable for this purpose, but it is used an order of magnitude less often, since without the introduction of certain additives it also cracks. It is better to use gypsum as an additional binder in an already prepared clay mortar to accelerate its setting and drying time.

In addition to gypsum, asbestos fiber is used as an additive to clay. It helps to make the plaster more ductile and durable, resistant to moisture and fireproof. This component can be added to any furnish for furnaces, regardless of its other composition. Instead of asbestos fiber, a cheaper straw section is sometimes used.

Clay-sand mixture

The most inexpensive and popular solution for plastering furnaces is clay-sand. The main raw material - clay for plaster - can be collected independently and completely free if there is a quarry nearby. The main thing is that it is clean, without debris, grass, roots and other impurities. Usually, 2 parts of sand are introduced into 1 part of clay, if desired, 1/10 part of asbestos is added.

The finished plaster is rather plastic, easy to apply on the surface, and it can be easily repaired if damaged. The mass is considered practically wasteless, because it can be removed, soaked and applied again. Plaster is non-flammable, 100% eco-friendly, vapor permeable.

The thermal conductivity of the mixture is low, so it retains the heat of the furnace for a long time. Clay cures rather slowly, which allows you to work with it without much haste (this is very important for beginners). The disadvantages of this type of mixture for plastering furnaces include the need for a fairly thick layer. If it is less than 1 centimeter, it will gradually fall off.

to contents ↑Cement-clay-sand mixture

This refractory plaster has a more complex composition, but the finished coating is even stronger, more reliable. Initially, cement is mixed with sand (1: 4-1: 8), mixed well and paste-like clay is introduced to obtain the mass of the desired consistency. Such plaster is stacked worse than regular clay, but lasts longer. To further enhance its strength characteristics, 1 part of liquid glass is introduced into the composition. As a result, the plaster layer will not be at all prone to cracking.

to contents ↑Lime and clay sand plaster

Adding lime to a clay and sand based solution provides increased adhesion, strength, ductility, and resistance to cracking and biodeterioration. Usually for the manufacture of plaster, slaked lime (1 part) is mixed with the finished clay-sand composition (2 parts).To improve the properties, the introduction of 1/10 part of asbestos fiber is allowed. The use of such plaster will be even more effective if, instead of ordinary clay, it is made on the basis of fireclay, which is obtained by burning kaolin at a temperature of about +1500 degrees with further grinding.

to contents ↑Popular ready-made mixes

In building stores you can find ready-made plasters that are sold in the form of dry building mixtures and are ideal for furnishing furnaces:

- Plaster for stoves and fireplaces "Pechnik". It is characterized by fire resistance up to +600 degrees, made on the basis of clay, sand, cement, gypsum, mineral and polymer additives. It has a low consumption - only 1 kg / 1.4-1.5 square meters. m

- Plitonit "Super Fireplace Refractory". Suitable for plastering brick ovens and fireplaces, since it is close to this material in terms of thermal expansion coefficient. It is made on the basis of clay, cement and heat-resistant fibers. It is characterized by high water-holding ability.

- Terracotta mixture is heat-resistant. Mineral plaster based on kaolin clay with a smooth texture, is applied with a layer of 2.5-8 mm. Terracotta plaster withstands heating up to +400 degrees, so it is great for decorating and leveling stoves, fireplaces, barbecue, barbecue areas.

- Plaster modeling TSP-4. Contains mineral granules 0.5-1 mm in size, designed specifically for plastering furnaces with the last (finishing) layer. Ideal for thin coat finishes. Withstands heating up to +200 degrees. It has high resistance to cracking due to the presence of water glass.

- Plaster for a fireplace of KODRU. It is not afraid of heating to +1270 degrees, does not shrink and is not covered by cracks. Due to its high elasticity, it is suitable for any heated areas, including stoves, fireplaces, pipes.

Mortar plaster mortar

If you want to make plaster for the oven, you can do it yourself. It is only important to properly prepare the clay in advance. The raw materials are soaked with water for 5 days, then washed again, removing the emerging debris. After undertake the following:

- water is finally drained, if small debris remains in the clay, pre-filtered through a sieve;

- mix the clay to a homogeneous state, remove any lumps (they will cause the appearance of cracks);

- separately prepare river sand - sift, wash, dry;

- asbestos is fluffed, milk is made from lime by mixing with water (if these additives are planned to be put into plaster);

- connect the main components together, add water to obtain a plaster with the desired texture (like thick sour cream).

to contents ↑Experienced plasterers add table salt to the finished composition - 200 g per bucket of finished plaster. Salt interferes with cracking of the solution, slightly slows down the solidification of the mass, and allows the coating to dry evenly. If the stove is heated with coal, peat briquettes, it is advisable to introduce a little fireclay clay into the plaster, which will give the mixture additional heat resistance.

Plastering tools

In order to apply the plaster mass in a quality manner, all the necessary tools are prepared in advance, and in the process, those that are more convenient to use are used. They also buy a primer that will enhance adhesion to the mortar and strengthen the masonry, metal corners, tile glue, beacons, a little gypsum plaster.

Here is a list of accessories that may be useful to the master:

- trowel, trowel - for applying and distributing the solution on the surface of the furnace;

- spatulas of different sizes - for applying, leveling, smoothing the composition, especially at corners and in other hard-to-reach places;

- construction grater, grater or trowel - for leveling and rubbing the surface;

- brushes and rollers - for painting dried plaster;

- chisel - for applying notches to the surface before plastering, if it is too smooth and does not adhere well to the mortar, and reinforcement has not been carried out;

- hammer - for fast beating off the old mortar;

- scissors for metal - for cutting reinforcing fabric;

- level and rule (plumb) - for proper alignment of the coating;

- construction mixer and suitable container for mixing plaster;

- hard metal brush - to remove old plaster and clean joints.

How to plaster the oven: instructions

Before starting work, the foundation is carefully prepared, because the quality and durability of the plaster layer will depend on this. The walls of the stove or fireplace are freed from the old coating - knocked down with a chisel and a hammer. Seams are cleaned well with a brush to remove pieces of plaster and sweep away dust. If the masonry is fresh, adhering and crawling out drops of mortar are removed, which can lead to the detachment of new plaster.

Old paint is completely cleaned off. Irregularities, cracks on bricks are covered up, masonry seams, on the contrary, are deepened by 5-10 mm. If the base is too smooth, make small cuts on it. The walls of the stove or fireplace are primed 2-3 times. Seams are especially well smeared with soil.

to contents ↑

Reinforcement

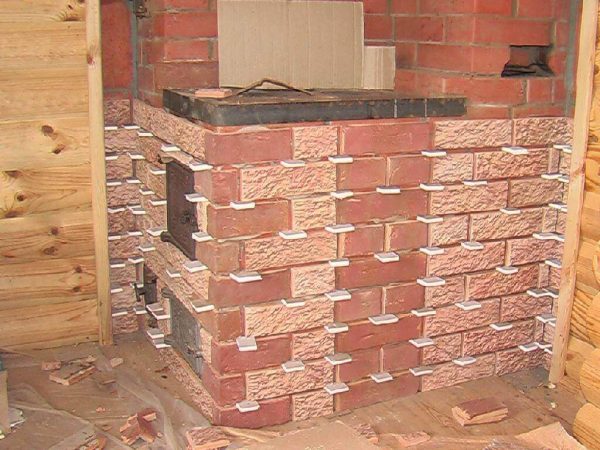

If the walls of the furnace are uneven, you will have to apply several layers of plaster. In this case, the carcass reinforcement is necessarily made, otherwise the solution may peel off and crack. A metal or fiberglass mesh with medium-sized cells (1.5-2 cm) is purchased. The metal material is fastened with wide-nailed nails, driving them directly between the bricks.

to contents ↑Fiberglass is attached to a mortar or to a heat-resistant tile adhesive. On the corners of the furnace with the aim of their ideal removal, steel or aluminum corners with perforation are attached to the glue. With a sharp roughness of the walls, the plaster is carried out by beacons, which are placed on top of the reinforcing mesh on small piles of gypsum mixture. Lighthouses are set by level, having previously determined the point of greatest deviation of the plane.

Splashing

For proper alignment of the walls, it is necessary that the plaster layer is at least 8-10 mm - this is the only way to get rid of significant distortions. After the grid is fixed on the surface and the beacons are exposed, the stove is heated to a warm state.

Then spray the walls of the furnace with water with a wide brush and spray. This is the first plaster layer up to 4-5 mm thick, which literally throws itself on the wall. The spray solution has a consistency of sour cream of medium density. After filling the entire area, the plaster is leveled without much effort, but paying attention to the quality filling of masonry joints. Allow the composition to dry well.

to contents ↑Alignment and Coating

After the first layer has dried, proceed to further work. Apply the solution with a spatula or trowel between the beacons, starting from the bottom of each wall, immediately level out with a small rule. After processing one area, proceed to the next until the entire surface is covered with a solution. Allow the leveling layer to dry, then proceed to cover.

to contents ↑The covering layer is only 1.5-2 mm in thickness, so the solution for it is made more liquid. It is needed for perfect surface leveling before painting. If you plan to stick tiles, do not necessarily cover. As this stage of work is completed, the lighthouses are cleaned, the holes are closed with a plaster mixture. The corners are carefully treated with an angular spatula, rounding for their own safety.

Grout

While the surface has not yet dried completely, they begin trowelling. Grind with a building grater or gunny, not forgetting to regularly moisten the device with water. Drive the tool circularly, increasing pressure in the cavities and decreasing in the fossa. To reduce the risk of cracking the layer, experienced craftsmen cover the oven with wet burlap after finishing the plastering work. As a result, it dries more evenly, which improves the quality of the result.

to contents ↑Oven decoration

For the final facing of the furnace, you can use a variety of materials - from inexpensive to luxury. If we are talking about the fireplace of a country house, they often use marble, granite in the form of plates, stones, as well as a coil or onyx. The ideal material for fireplaces and stoves is marble, which is not afraid of sudden temperature fluctuations and has a long service life. More economical finishes are whitewashing, staining, drawing, or gluing tiles.

to contents ↑Coloring and whitewashing the furnace

The simplest method for finishing a furnace is whitewashing. To carry out whitewashing, a solution is prepared from 100 l of liquid lime and 100 g of non-iodized salt, you can also drip a little blue. A more modern option is to color the stove with heat-resistant water-based paints. Oil coatings are not used for this purpose - they quickly darken, moreover, they can release toxins when heated. Before whitewashing or staining, the surface of the plastered stove is primed.

to contents ↑Decorative plaster for stoves and fireplaces

Decorative plaster is another easy-to-use and beautiful material that can be used to decorate a stove or fireplace. It is important to pay attention to the quality of the mixture and its suitability for furnishing furnaces, since not all brands are suitable for this purpose. On sale there are heat-resistant decorative compositions of different manufacturers. Also, instead of specialized tools, you can choose a plaster for outdoor work, which is not afraid of sudden temperature changes.

to contents ↑Mineral-based decorative plasters withstand high temperatures when heated, while clay or lime-based mixtures are most suitable. Also suitable for work are silicone or silicate compounds. As it dries, a coat of paint, varnish or wax can be applied to the decorative plaster.

Tile

Terracotta or ceramic tiles are often used to finish the furnace after plastering. It is glued to a heat-resistant tile adhesive, which is designed to work with very hot substrates. The usual adhesive for tiles will not work - the material will quickly peel off from the oven. On sale there are even special corner ceramic elements that simplify the work and make the stove beautiful and stylish.

Tips for plastering stoves

Professionals point to a number of important nuances that must be taken into account when self-facing a stove or fireplace:

- With a strong and regular glow of the structure, it is important to choose a special primer for work, which is heat-resistant. The use of ordinary soils can cause the solution to snap off from the furnace.

- Plastering can only begin after some time has passed since the construction of the furnace. It is better if it will be at least 2-3 months, and during this entire period the furnace should be regularly heated. This will reduce the risk of shrinkage in the future.

- After finishing activities, the stove can be warmed up after 3 days, when the coating ceases to be pressed when pressed with a finger. The first time they drown not at full power, then the heating temperature is gradually increased. After the furnace, the blower is not closed to ensure the natural evaporation of moisture from the plaster.

- Whitewashing, tiling or staining of the oven is started about a month after plastering.

to contents ↑

Repair of stove plaster

If cracks still appear on the furnace coating, this means a violation of the plastering technology or improper operation of the structure (overheating, loosening of the doors, etc.). In difficult cases, you have to shift the oven, but most often it helps to carry out "cosmetic" repairs. Work is carried out in the following sequence:

- Completely remove the old plaster and whitewash from the surface of the damaged area, remove soot, otherwise the latter will come out from under the solution layer in the form of rust spots.

- Cracked bricks are repaired with a special repair mixture or fill cracks with heat-resistant mastic. If repair is not possible, the bricks are replaced with new ones, but plastering is started no earlier than 7 days later.

- The primer is applied with a brush and allowed to dry.

- A plaster composition is prepared, applied to the area moistened with water by throwing. After leveling the solution, wipe it with a construction grater.

- The loose doors are reinforced with wire, a clay composition is also applied around the fastening zone. Let the stove dry.

With the correct manufacturing of plaster, the furnish of the furnace or its repair can be done by yourself. The costs of such work will be small, and the cost savings of invited artists will be substantial.