Many manufacturers of building materials make decorative stone from gypsum, which is very popular in the decoration of residential premises. It looks beautiful, suitable for different interior styles, however, the price is quite high. If you wish, you can prepare a mixture for making stone and pour it at home.

- Plaster facing stone: properties

- How to calculate the amount of decorative stone on the wall?

- The technology of manufacturing decorative stone from gypsum

- Necessary materials and tools

- What gypsum is needed?

- How to make a mold for a decorative stone with your own hands?

- Workplace preparation

- Making gypsum dough

- Calculation of gypsum per mold

- Color creation

- Form (matrix) processing

- Pouring process

- Formwork

- Stone drying

- What to glue gypsum decorative stone?

- Special adhesives

- Compatible Compounds

- Tools at hand

- Laying decorative stone

- Protective compound

- Stone painting

- Using gypsum varnish

- Varnish for gypsum decorative stone: types

- Shellac lacquer

- Acrylic Varnishes

- Oil varnishes

- Yacht varnishes

- Rules for varnishing

Plaster facing stone: properties

Gypsum stone is an artificially created material and looks like decorative tiles. Beautiful masonry is perfect for wall cladding, door, window openings, fireplaces, suitable for fragmentary or complete decoration of premises.

Features of gypsum decorative stone:

- Simplicity of work. The shape of each element can be changed: trimmed with standard construction tools. The stone can be easily glued to any kind of surface.

- Ease. Gypsum practically does not burden the weight of the wall, does not give much pressure on the foundation and floor, even when fully finished.

- Improving the quality of life indoors. If you glue the walls with decorative stone, the sound insulation will seriously increase. In addition, the material provides additional thermal insulation, while it is breathable, does not violate the vapor permeability of the walls.

- Harmlessness. Gypsum is a natural material, it does not contain harmful additives, it does not emit toxins into the air, but by itself it protects the walls from the colonization of mold and fungus.

- Compatibility Decorative stone can be docked with tiles, wallpaper, plaster, wood trim, photo cloths. It also looks good along with stucco moldings, moldings, and other decor.

- Long service life. The material serves for many years, especially when using varnishes, special protective impregnations. It is quite durable, it is damaged only with strong mechanical stress.

to contents ↑The main component of the stone is gypsum, which is mixed with sand, water, modifiers. To give a certain shade to the mass add pigments. Gypsum stone can be styled as brick, tile, different types of natural stone - the range of products in construction stores is quite large.

How to calculate the amount of decorative stone on the wall?

If you have to buy a stone in finished form, it is important to calculate the right amount of material in advance - this will help to avoid unnecessary expenses. For any group of elements, add 5-10% for breakage, improper cutting, other flaws in the work.Most craftsmen lay stone without leaving seams. When facing walls, taking into account the gaps, you can not make an increase in error.

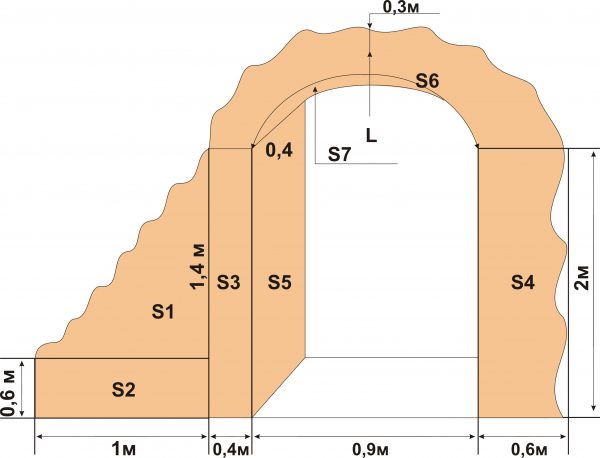

The order of counting elements:

- Flat parts. You should multiply the length of the wall by the width to get its area. Then, in the same way, calculate the area of all openings (windows, doors, niches, arches) and subtract from the total, because they are not lined.

- External corner parts. The assortment of most companies has special elements made of decorative stone. They only trim the outer corners of windows, doors, niches. Having measured all the lengths of the angles, they need to be added together, getting the number in linear meters.

- Internal corner parts. For arrangement, you will have to trim the flat stone. It is necessary to calculate the length of the inner corners in running meters, multiply it by the overlap coefficient (0.25). It will turn out the area of the wall covering with corner elements in square meters (it is already included in the main one and is calculated for reference).

The technology of manufacturing decorative stone from gypsum

Professional production takes place in the factory using special equipment. But a decorative stone can be made independently, for your own purposes and even for sale. It is only important to strictly observe the technology, because without following the norms, gypsum will remain fragile, short-lived.

to contents ↑Necessary materials and tools

First you need to buy forms that can be silicone, plastic, polyurethane. If desired, they can be made independently. The most durable and comfortable are polyurethane products. In homework with gypsum, some craftsmen use molds made of metal, wood, but they are not flexible, so it will be difficult to extract the finished elements.

To work, you will need:

- white powder gypsum;

- a bucket for a batch - plastic with a flat bottom, not wide (a cropped bottle and a canister are also suitable);

- Libra;

- sand;

- pallet;

- drill or screwdriver with a nozzle;

- polyethylene or glass;

- laundry soap;

- beaker;

- atomizer;

- water;

- putty knife;

- dye;

- wax or turpentine.

What gypsum is needed?

Gypsum of different brands is sold in stores - expensive and cheaper. There is always an R on the packaging with a number: the larger it is, the stronger, more reliable the gypsum. The most fragile material R-6 is also suitable for work, just wall decoration will need to be carried out with more care.

Gypsum R-16 is the most durable and expensive, it is usually used if the finished decorative stone is to be transported, sold. Also in stores there are gypsum mixtures with plasticizers and additives introduced into them, which increase the strength of the material. The color of the powder also needs to be given close attention. Gray is stained worse, and the result can be ugly. An ideal option is a durable white gypsum of the finest grinding.

to contents ↑How to make a mold for a decorative stone with your own hands?

If you decide to create forms yourself, this stage of work should be the first. An additional list of materials and tools will be required:

- smooth, varnished plywood or chipboard sheet with sides made of the same material - they must have a height of 5 cm, fastened with euro screws;

- fiberboard dividers 5 cm high;

- flat table indoors;

- acrylic sealant;

- polyurethane;

- machine oil;

- large stones with the desired relief;

- liquid nails, superglue;

- building hair dryer;

- marker.

First you need to prepare a master model with which the cast will be taken. To do this, stones with a suitable relief on one side and absolutely smooth on the other are selected. Their shape can be any (it does not matter), the thickness is 10-50 mm. The stones are laid out on the mold board so that the gap at the walls is 1.5-2 cm, and they are outlined with a marker. Glue is applied to the flat side, elements are glued.The cracks between the board and uneven edges are filled with acrylic sealant, 5 cm high boards are installed directly through it.

The upper part of the stones is lubricated with a release agent - machine oil. The procedure is performed several times to well fill the pores of the elements. Prepare polyurethane strictly according to the instructions, fill them with formwork. They let the “liquid rubber” dry, then they separate the mold from the master model and proceed to further work on making the stone.

to contents ↑Workplace preparation

To remove the decorative stone was easy, the mold is wetted with water and laundry soap. The solution for the forms should not be too saturated, it is enough to introduce only a little planed soap. Shake the liquid, pour it into the spray bottle.

to contents ↑The form is placed on the table, sprayed with a solution. The mixture should not flow down the walls, you just need to slightly moisten the molds. Some masters prefer to lubricate the form with a mixture of wax and turpentine (3: 7), previously melting the wax in a water bath. All the necessary materials, tools are placed nearby so that they are available during the work.

Making gypsum dough

The volume of the solution should correspond to the number of forms, otherwise the excess gypsum will harden, deteriorate. In any case, you will have to dilute the material again for the next fill. Water is poured into the container, then a little gypsum powder is poured into it, stirring with a drill. The result should be a fairly dense mass. To harden the solution add white quartz sand, not more than 10%. You can’t put all the gypsum into the liquid at once: it will be unrealistic to mix it, as a result, many lumps will remain in the bucket.

to contents ↑Calculation of gypsum per mold

When buying forms on the packaging, you can see information about the amount of gypsum dough that is included in it. If the forms are made independently, or there is no exact data on the volume of gypsum, you can do otherwise. Dry gypsum powder is filled into the mold, excesses are removed from above with a metal spatula. Pour it into a bucket, weigh it, separate about 30% - this part is not required. After diluting the material with water 1: 1 - usually this amount is enough to fill out the form. The exact amount of the substance should be remembered in order to know in the future how much mass needs to be prepared per filling.

to contents ↑Color creation

A coloring substance is introduced into the gypsum dough. If it is in the form of a powder, it is separately diluted with a small amount of water. The mass is mixed with a construction mixer until smooth or create the effect of uneven coloring, streaks.

to contents ↑Form (matrix) processing

Lubricated from the inside of the mold is covered with a thin layer of gypsum dough. If you do not apply the material to the inner surface of the molds, “sinks” will often appear in the finished stone: ugly notches, voids. After the form put in pallets, placing the latter on a flat table.

Pouring process

Mixing the gypsum mass for too long is not worth it: it quickly sets and can begin to harden already during preparation. Immediately after kneading, the dough is poured into molds, the top is leveled with a spatula. It is impossible to press hard on the tool: this can lead to the appearance of recesses. A few minutes after pouring, they carefully again pass along the future stones with a spatula for the final alignment of the back side.

to contents ↑Forms are closed with polyethylene or glass, subjected to slight vibration to remove internal bubbles, voids. The plaster is allowed to harden for 20 minutes, then the film is removed, the stones are removed.

Formwork

The layout is done in this way: the edge of the form is pulled down to the table so that it hangs in the air. Separated tiles are gradually removed, stacked on pallets. You can also flip the form, shake out the elements, but you have to act with extreme caution.

to contents ↑Stone drying

In summer, tiles can be laid out on the street or in a greenhouse - so they quickly dry out naturally. A special dryer should be purchased for those who are not able to ventilate the material, or for craftsmen who make stone for sale.

What to glue gypsum decorative stone?

Among the adhesives that are well suited for the installation of decorative stone, we can name specialized and some universal tools. Also, a number of users use improvised compositions for fixing the material.

to contents ↑Special adhesives

Most often, experienced craftsmen prefer to attach gypsum to special adhesives, which are ideal for work on concrete, plaster, drywall. Glues are sold in the form of dry building mixes, are made on the basis of gypsum or alabaster and include hardeners, plasticizers, special additives that enhance adhesion and elasticity. Such tools can repair damage in individual elements of the gypsum stone, if they have small cracks.

When buying glue, you should pay attention to the presence of quartz sand in the composition. It is ideal for improving the properties of cement adhesives, but is not valuable for gypsum mixtures. Sand is used by manufacturers only to reduce costs, so it is better to choose adhesives without it. If the instructions indicate that less than 0.3 liters of water is needed per kilogram of dry powder, there are too many other additives in this product, but not enough gypsum (alabaster). Such a composition will be fragile, and it is better to refuse to buy it.

When choosing a specialized tool for gypsum stone, it is necessary to take into account the solidification time of the solution. High-quality adhesives dry out in 25-30 minutes, they need to be prepared in small portions, but you do not have to hold the elements for a long time with your hands. You also need to carefully evaluate the composition of the glue: it should not contain toxic components, because working with the product most often has to be done indoors.

to contents ↑Compatible Compounds

In addition to specialized dry mixes with gypsum, alabaster for gluing stone, glues for ceramic tiles and porcelain tiles are well suited. Often they are also made in the form of powder, sold in bags of 10–25 kg. Such funds are strong, reliable, durable, easy to apply, but have a minus: they dry for a long time, and it will take longer to press the elements to the wall. As for the high degree of adhesion to the surface, with respect to gypsum, this has no practical value: the elements are very light and hold well on the wall.

to contents ↑Also in stores there are ready-made compositions for tiles and adhesives such as liquid nails. It’s easy, comfortable to work with them, the time before setting the funds is minimal. But the price of such adhesives is quite high, so they should be used for fragmented decoration or repair of a small area of decorative stone.

Tools at hand

Some putties for roughing or finishing contain alabaster. They can also be used for gluing gypsum decorative stone. Putty is bred a little thicker than for plastering the walls, elements are glued, after the base has been treated with a latex primer. To reduce the drying speed of alabaster, you can drip a little liquid soap into the diluted composition. In addition to putty, other paint mixes, including cement, are also suitable for gluing gypsum parts onto walls.

to contents ↑Laying decorative stone

Before decorating the walls with gypsum stone, they must be primed, choosing a tool depending on the type of base. For concrete walls, deep penetration soils are most often bought, for highly absorbent surfaces - latex. It is better to apply 2-3 layers of the composition, which will seriously improve the adhesion of the adhesive to the wall. The seams on the brick bases are leveled, sealed with putty using a narrow spatula.

Elements of the stone are cut according to the outlines of corners, protrusions, and other non-standard parts. This can be done with an ordinary hacksaw. Stick on a decorative stone only after the primer has completely dried.With a convenient spatula, glue is applied with a layer of up to 1.5 cm on the stone, pass along it with a comb to remove excess funds. The spatula is regularly washed with water to remove the remnants of dried glue, otherwise it will go down in clumps.

After the installation of the coating is completed, the glue that has come out is removed from the surface of the stone while it is still dry. They wait 24 hours to gain strength, but at high humidity this period can be increased up to 7 days. Only then can artwork be done.

to contents ↑Protective compound

Even before varnishing or staining the stone, it is necessary to impregnate it with a special hydrophobic agent. It is required to reduce hygroscopicity, prevent moisture saturation, and reduce the risk of mold growth. In stores, ready-made liquid formulations or concentrates are sold that you need to breed with your own hands. Good impregnations for decorative stone are:

- "Optimist C405";

- White Hill

- Tiprom and others.

Application of the solution does not lead to the appearance of a film that could disrupt the vapor permeability of the surface. The product penetrates the gypsum by 10-15 mm, which eliminates its damage when applying paint. It is usually recommended to make 2-3 layers of protective agent one after another, without waiting for the previous one to dry completely. The easiest way to work with a spray gun, but you can use a conventional roller.

to contents ↑Stone painting

For staining the stone, silicone, silicate, acrylic, latex products are used. Most of them are water based. If the paint is used for outdoor use, it must be resistant to external influences. Typically, decorative stone is processed, the composition of which was not introduced dye in the manufacture.

In order for the paint to lay down better, it doesn’t fade longer, the primed stone is first primed with protective compounds with the effect of hydrophobization, which reduce water absorption by 20–25 times. To get a glossy effect, a special varnish should be used instead of paint.

to contents ↑

Using gypsum varnish

Standard gypsum products are grayish or white, and their coloring or tinting with colored varnish will help to give the wall the desired look. With its help, you can design the surface in an original way, stylize it in accordance with the chosen direction in the interior. Varnishing helps to increase moisture resistance, because in contact with moisture gypsum products deteriorate. After varnishing in several layers, a decorative stone will be suitable even for finishing wet rooms. Also, applying varnish reduces the susceptibility of tiles to impact.

to contents ↑Varnish for gypsum decorative stone: types

On sale there are varnishes of various types, compositions, with different characteristics and properties.

Shellac lacquer

Usually this type is used in decoupage, but it is often used in finishing works. Shellac is made on an alcohol basis, so it is well suited for gypsum. It can be applied as an independent coating or on top of any paint. Shellac creates a thin polishing layer that looks stylish and very attractive.

to contents ↑The composition is transparent and colored. There are even special varnishes with aging effect, used to give the base a vintage look. If you connect the product with rosin in a 1: 1 ratio, a protective film will be created on the surface of the gypsum, eliminating the appearance of contaminants and giving the wall a marble look.

Acrylic Varnishes

Acrylic based varnishes perform a decorative and protective function. They are moisture resistant, do not deteriorate from the action of household chemicals, ultraviolet radiation, temperature changes, dry quickly, do not have a pungent odor. When thickening, acrylic varnish can simply be diluted with water.

In appearance, coatings with acrylic can be matte, semi-gloss, glossy. Matte help give the stone the appearance of a natural, rough material. Semi-gloss varnishes work in the same way, only their transparent varieties, after drying, can leave a light, light coating.Glossy products glisten, lead to glare, which must be taken into account when planning the situation in the room.

to contents ↑Oil varnishes

The composition of oil varnishes includes artificial resins, vegetable extracts. After application to the gypsum stone, a thin film is formed that protects the material from any external factors and extends its service life. Oil-based varnishes can be transparent or colored, glossy or matte. After drying such a tool, the surface of the decorative stone will look a little darker than originally.

to contents ↑Yacht varnishes

The most durable, durable and reliable stone varnish is considered yacht. It has a high degree of water resistance, which makes it suitable even for yachts. It contains solvents, it smells unpleasant and is more suitable for outdoor use, although after complete drying it ceases to be toxic. For maximum surface protection, yacht varnish is applied in 2 layers.

to contents ↑Rules for varnishing

Before performing the coating, you need to make sure that all the elements have dried well after priming or protective hydrophobization. The adhesive, to which the decorative stone was joined, must also dry out, otherwise the integrity of the lining may be impaired.

Tips for varnishing a stone:

- rough parts should be sanded before spraying the varnish, sandpaper with fine grain is well suited for this purpose;

- if the stone has been impregnated, you need to read the instructions for it and clarify the possibility of subsequent varnishing and compatibility with a particular varnish;

- brilliant compositions reduce the effect of naturalness of the stone, so for country styles, Provence and other areas that strive for naturalness, it is better to choose matte products;

- before varnishing from a stone it is necessary to brush off all the dust;

- during operation, you can not moisten the wall or elements - they quickly absorb moisture;

- the most convenient method of varnishing is spraying from a spray gun or airbrush.

By connecting your imagination to work, with the help of decorative stone you can find very interesting solutions even in a small apartment. This material looks unusual, fresh and gives the house a special touch, fills with warmth and comfort.