Powder paint is the end product of the evolution of coloring materials. Thanks to an impressive list of positive properties, it is a worthy alternative to traditional paints and varnishes. It has been widely used in many industries. A coating based on this substance is used in the automotive industry, in the construction industry, and in the manufacture of household appliances and furniture. It is actively used even when decorating home decoration.

- Material structure

- Physics of the staining process

- Material classification

- Thermoplastic

- Thermosetting

- Surface type

- Application in car repair

- Work stages

- Advantages of use

Why is this material in demand? How important are its benefits? What is the high technology of this painting method?

to contents ↑Material structure

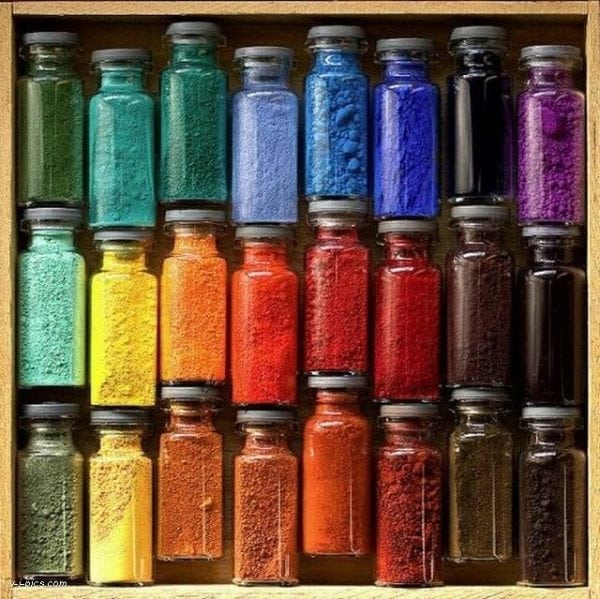

By its structure, this coloring matter is a dispersive multicomponent mixture of solid particles. Its basis is powder polymer and pigment. The constituent elements of the dispersion powder vary depending on the functional purpose and scope of the paint. The composition is diverse. This may include a variety of impurities in the form of:

- fillers, for example, aluminum oxides or titanium dioxide;

- pigment to obtain a variety of color depths;

- hardeners of epoxy resins;

- film-forming resins;

- additives of various acrylates.

One of the most important advantages of a powder product is that it does not contain solvents that are highly toxic and flammable. That is, it is practically safe for humans, does not have a harmful effect on the natural environment.

All components of the paint base are dry, do not stick to each other, have excellent flowability. The consistency of the powder does not change with time, does not thicken. Therefore, there is no need to dilute it with the help of special solvents, unlike water-dispersion paints, for example, acrylic.

Such pigment quality indicators as adhesion, electrification ability, flowability directly depend on the properties of the pigment.

The amount of fillers and pigment may be more than half of the total composition. This is determined by the color depth and purpose of the product. The pigment used for this coloring material is no different from the pigment that is added to other liquid, such as acrylic coloring materials.

to contents ↑Physics of the staining process

The particles of the dyeing product are transferred by a third-party electric field to a charge opposite to that of the surface intended for painting. Charged powder particles are forced to settle on the product, forming a layer of small thickness. A special spraying chamber catches charged specks of paint, which have electric field strengths that are insufficient for adhesion to the charged plane of an object, and uses them again for painting.

There is the possibility of re-spraying components that do not adhere to the machined plane. The powder is consumed completely. This leads to a high rate of profitability of this technology.

Then begins the baking of the sprayed surface. The painted product is transferred inside a special chamber.Inside the furnace at high temperature, the coating polymerizes.

to contents ↑Material classification

It is customary to classify the coloring material according to the type of polymers included in the composition. In view of the main components, the paint may be suitable for use outdoors or indoors. The most popular grouping is by the method of film formation on the surface and by the method of solidification of the layer.

It is customary to distinguish two large classes of paints according to the type of film-forming substance. Thermoplastic and thermosetting paints are the main types of powder paints according to the type of film-forming abilities. They also have a branched classification.

to contents ↑Thermoplastic

Thermoplastic powder paints contain coloring components based on substances that form a coating in the form of a film due to the melting of the paint elements and their cooling. The formation of a layer is not accompanied by chemical reactions. However, the film may dissolve if the temperature is not observed. The choice of paint is made depending on the conditions:

- For decorative purposes, thermoplastic paint is used, the basis of which is vinyl. This coloring matter is suitable only for indoor painting, while its sufficiently small thickness gives good protection against moisture at room temperature.

- Polyvinyl chloride based paint is suitable for outdoor applications and indoor surfaces. It is characterized by high weather resistance and resistance to chemicals.

- High physical and mechanical properties of the layer based on polyethylene have led to the fact that this polymer paint is actively used for painting pipelines for various purposes.

- Polyamides, which are part of polyamide paint, have high aesthetic attractiveness, are used for decorative purposes for painting both indoors and outdoors.

Thermosetting

Thermosetting powder paints are a thermosetting film former. Here, the composite particles are fused and a chemical reaction takes place. Their advantage is that the coating does not melt and does not dissolve, is characterized by high hardness and resistance to various defects. Therefore, paint is actively used in mechanical engineering. It may include various epoxy and polyester resins.

Powder paint of this type requires strict adherence to the painting procedure. Only in this case can a positive result be achieved that meets all the parameters of color fastness and weather resistance. Paint Features:

- Epoxy substances give it high mechanical strength and durability. However, significant defects can form on the surface under the influence of solar ultraviolet radiation.

- Compared to epoxy dye, polyester paint not destroyed in the open air, used for painting outdoors. It features high color stability.

- Acrylate base provides high resistance to a variety of alkaline compounds. The saturation of the color pigment persists for a long time.

Surface type

The surface treated with this paint may have a matte or glossy effect. The composition of the matte coloring matter includes scaly particles. The difference in the reaction characteristics of the impurity provides a matt appearance. It is mainly used in mechanical engineering.

The composition of the gloss paint contains various epoxy, polyester film formers. Also, its basis is the pigment necessary for the implementation of a certain color.

The glossy surface is characterized by high reflective properties, resistance to corrosion processes, which is important for the automotive industry.

to contents ↑Application in car repair

At the moment, most often, acrylic dyes are used to mask defects on automobile rims. Their practicality lies in the fact that they can be sold in cans, which is very convenient for painting. You can get a quality result if you carefully spray acrylic paints in a small layer. The attractiveness of these cans is that with their help you can get a glossy surface. Buyers are offered a huge selection of colors. A significant minus of acrylic painting materials - they do not provide chip recovery.

For reliable chip recovery, the damaged surface must be primed. Powder paint has good adhesion with a primed coating, that is, it adheres well to it, qualitatively hiding defects. In the assortment there are spray cans that have a different concentration of pigment and can achieve different color depths. They are able to recreate a glossy surface.

to contents ↑Work stages

The basic basis of work on painting metal surfaces includes three stages:

- To begin with, metal parts that are painted should be prepared by removing all contaminants. To improve adhesion, the surface needs to be degreased.

- In the chamber, spraying is applied with a thin layer.

- At the final stage, a film is formed.

Advantages of use

The main advantageous qualities of the powder-based coloring material are as follows:

- creation of a solid and high-quality surface;

- harmlessness to man and nature;

- affordability;

- profitability;

- even thickness of the layers of paint;

- high pour point;

- high strength paint of small thickness.

About one sixth of all paint is used for surfaces coated with high-tech low-temperature paint. But now, thanks to the development of technology, there is a tendency to steadily increase this figure in favor of powder-based paints.

Very sensible, capacious, easy to understand article. It is interesting to get acquainted with your recommendations regarding the coloring of metal furniture made of steel and aluminum.