Corrosion reduces strength and worsens the appearance of metal structures, leading to their complete destruction over time. Polyester paints perfectly protect the metal from rust, while giving it an aesthetic appearance.

General characteristics

Solid dispersed structures in the combination of which are film-forming resins, hardeners (desiccants), various pigments, as well as installation additives are called powder paints.

Such compositions are inherent in:

- homogeneity (uniformity of composition);

- physical and chemical constancy;

- invariance of the mixture during operation and storage.

Polyester powder paints are produced as follows: all components are mixed, then homogenized (this occurs at high temperature in a twin-screw extruder). The finished melt is cooled, crushed and sieved, thereby achieving uniformity of the powder. Such paints are used exclusively for metal surfaces. However, over the past decade, several types of powder coatings for plastic and wood have been created.

Such paints are distinguished by environmental safety, good protective properties, decorativeness. In addition, they are economical. Staining takes place in a special chamber, thereby achieving 100% use of the material.

Features of powder paint:

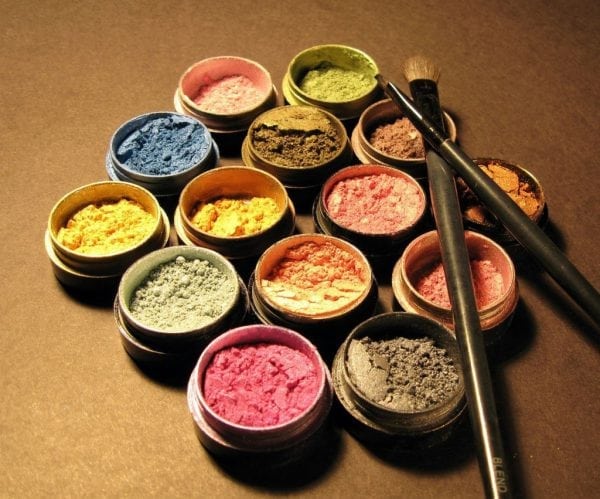

- decorativeness (the ability to use the widest color palette);

- reliability (high chemical resistance);

- the ability to get a fairly thick coating in one stain;

- complete absence of streaks on the verticals;

- good adhesion.

Varieties

Powder paints based on thermoset film-forming are widely used. They are divided into 2 types: polyester and epoxy-polyester.

Polyester Compounds

They are based on a special fine powder, in which polyester, pigments and additives are used, but at the same time there are no any solvents or epoxy resin.

Polyester paints are characterized by low toxicity, so they are used even for painting bicycles, car parts. They are designed for various metal surfaces that regularly experience various atmospheric effects (high / low temperatures, snow, rain, hail, wind). Resistance to temperature changes is very high. Application methods - electrostatic or tribostatic methods.

Among other positive characteristics:

- excellent filling and spreading rates;

- resistance to aggressive chemicals;

- drying speed.

to contents ↑Advice! Store paintwork materials no more than 12 months at a temperature of 25 ° C.

Epoxy polyester

These paints are based on polyester (up to 50 - 70% of the total composition) and epoxy resins supplemented with hardener, fillers and pigments (up to 35 - 50% of the total composition). They relate to powder enamels for internal use and have high strength characteristics:

- impact resistance;

- elasticity;

- resistance to solvents;

- good flowability.

Epoxy-polyester (hybrid) paints are used to paint and improve the appearance of metal products used indoors. It could be:

- electrical equipment;

- Appliances;

- tableware;

- Furniture for home and office;

- car accessories;

- heating appliances;

- travel supplies.

Staining methods: electrostatic or tribostatic. Epoxy-polyester compounds perfectly protect against corrosion, do not turn yellow when exposed to high temperatures.

to contents ↑Advice! When working with such enamels, be careful - wear a protective mask, special glasses and gloves.

Painting methods

There are 2 methods for applying powdered polyester and epoxy-polyester compositions - this is electrostatic and tribostatic spraying. A typical painting process consists of the following steps:

- Preparation of the base of the item for painting - rust strippingprimer treatment.

- Application of powder to the object to be painted is one of the most suitable methods for this.

- Polymerization at temperatures from 140 - 220 ° C. It depends on the type of paint. In the process of heating, the powder slowly melts, resulting in a solid uniform coating.

Manufacturers of powder paints produce compounds resembling chrome, patina, copper, anodized aluminum and some metals. Surfaces after staining can be glossy, able to hide minor defects, or textured, emphasizing dignity. The choice for the potential consumer is huge.