Welding is a mandatory process when joining metal, plastic products. Until recently, it was possible only with the help of special equipment, when the surfaces were melted and literally welded together. The new invention of mankind is cold welding - for plastic this method of connection is ideal, it allows you to quickly and safely get high-quality joints of parts.

- Welding Description

- The advantages of fluid welding

- Material scope

- Types of cold welding

- Welding Procedure

- Security measures

- Welding storage

- Expert Advice

- Suitable brands and selection rules

Welding Description

Cold welding is understood as processing with polymer glue, which helps to create reliable seams between the same or different materials without using heat. As a result, an integral connection of elements is achieved, this is facilitated by the special composition of the chemical mass. A plastic agent penetrates into the welded parts, then solidifies, forming a monolithic joint.

Cold welding includes the following main components:

- epoxy resin;

- amine resins;

- steel fillers;

- minerals.

to contents ↑Epoxy glue is perfect for plastic, metal, wood, but you need to study the instructions in detail. Universal compounds can really be used on any material, highly specialized ones are allowed to glue only one type of elements, otherwise the work efficiency will decrease.

The advantages of fluid welding

A huge advantage of the tool is the ability to repair almost any plastic product without heating, so you do not need to use appliances, welding equipment for work, special knowledge, long preparation are not required. You can’t do without a cold composition when docking complex parts, when installing fire hazardous, explosive structures. The tightness of the seams will be impeccable, because they will not leak moisture.

Other advantages of using cold welding:

- waste reduction;

- affordability and availability in stores;

- the ability to work even in “field” conditions (there is no need for electricity);

- highest bonding strength;

- the ability to connect parts experiencing vibration, shear and tear, due to good elasticity.

Almost any welding is waterproof, high temperature - universal compounds withstand up to +260 degrees of heating during operation, specialized ones - up to +1000 degrees.

to contents ↑Material scope

There are a lot of plastic items, and almost all of them can be repaired using cold welding technology. It is possible to repair the connector of a household appliance, restore its individual parts, and repair various defects and chips. Cold cracks fill any cracks, carry out cosmetic and full repair of such products:

- pipes made of heat-resistant and ordinary plastic;

- fishing rods, tourist uniforms;

- cases and handles of devices;

- car bumpers, interior elements made of plastic;

- garden, household, home tools, etc.

Types of cold welding

With a consistency, all means for welding are divided into liquid and plastic-like. In the first case, they are sold in bottles, bottles, boxes, in the second case the packaging resembles an adhesive pencil, a cylindrical rod, a tube.

The composition of the material is:

- single component;

- two-component.

One-component welding is always liquid, in consistency similar to clerical glue. It is used to join small, light parts, because the adhesive ability is not too powerful. Two-component welding - a more reliable composition. Before work, the resin is mixed with the hardener by combining the liquid components or manually mixing a plasticine mass. After the start of the chemical reaction, the user has a few minutes to work, otherwise the material will harden.

to contents ↑Welding Procedure

The instructions for use always describe in detail the process of mixing the components and applying the product. The proportion of hardener and resin must be observed strictly or the adhesion of the adhesive will decrease. The rules for surface preparation cannot be ignored. They need to be cleaned of dirt, treated with sandpaper, then degreased - wipe with alcohol, acetone. Without fat removal, it is impossible to reliably dock elements.

Further, the order of work will be as follows:

- mix resin and hardener or mix together thick components (the amount of mass should correspond to the area of the hole, defect, bonding zone);

- knead solid components need only in thick rubber gloves that are moistened with water; when ready, the mass will acquire a bright brown color;

- apply the product to fastened parts, use a clamp, cord, cord or elastic band to fix them;

- press parts, leave for an hour;

- then wait time according to the instructions or immediately proceed to further processing of the product (threading, painting, drilling).

to contents ↑

Security measures

After drying, the weld will be absolutely safe for humans, pets, it does not emit harmful fumes. But directly when working with epoxy resin, it is important to observe all safety measures. Do not allow skin contact with the material, before starting work, wear tight clothing, gloves. It is forbidden to work without personal protective equipment - masks, respirators. Good ventilation is necessarily equipped in the room, in a pinch, a window opens.

to contents ↑The mixture for welding should not come in contact with utensils, food, other objects that are used in everyday life and for food. If tar gets on your skin, wash it quickly with soap. The penetration of the composition into the eyes is a reason for contacting a doctor after preliminary washing with water.

Welding storage

You can not store the product so that direct sunlight falls on it, it is also forbidden to allow heating above +35 degrees, contact with moisture. During storage, animals and children should not detect welding. When the product dries, it can be slightly warmed up by putting it on the radiator for 15-30 minutes.

to contents ↑Expert Advice

There are a number of useful recommendations that will help you do the job with greater accuracy, efficiency:

- when repairing pipes, pipeline elements, you only need to buy a moisture-resistant composition, taking into account constant contact with the liquid;

- cold welding sticks poorly, grasps worse with a wet surface, therefore, before starting work, the base must be thoroughly dried;

- if you have to urgently seal a leak in a plastic pipe, later you need to change such a patch - adhesion will not be sufficient;

- for faster hardening of the mass, you can use a hairdryer with warm air;

- when the instructions do not indicate that the welding can withstand regular vibration, it is worth attaching an overlay to the junction of the moving elements;

- it is worth buying only funds from trusted manufacturers that have long been on the market;

- no need to use material with an expired shelf life, its quality is reduced.

Suitable brands and selection rules

Welding for plastic has less stringent requirements than for metal. It is better to immediately buy a two-component composition with a high degree of reliability. The following welds have proven themselves well:

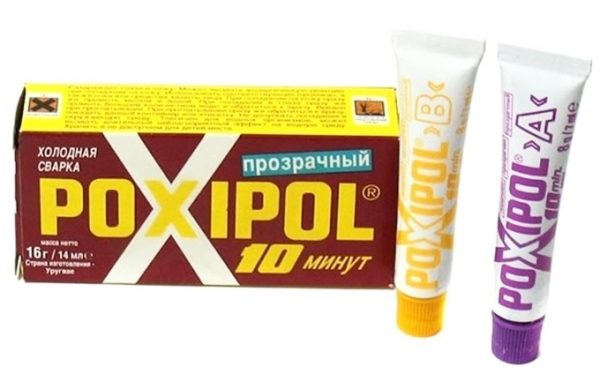

- Poxipol;

- Super Epoxy Moment;

- Titanium;

- Chipping;

- Diamond;

- EAF;

- Mastix;

- AVS Crystal;

- Second.

When choosing a material, you need to pay attention to the operating temperature. If the conditions are extreme, welding should be able to withstand them. Also, the manufacturer always indicates the permissible norms of pressure on the weld, in case of non-compliance, the connection will break. With a long duration of repair, it is better to buy long-hardening agents, when gluing small parts usually 3-5 minutes are enough time to set the composition. It is more convenient to glue thin parts with liquid means, tougher work is usually carried out with thick materials, they even the surface of the products.