On many metal structures, rust stains appear over time. To clean the metal before applying the finish or protective coating, a special treatment is required. The sandblasting machine, which ejects abrasive material from the nozzle and easily removes rust and other impurities, has proven itself in this matter. You need to choose the right sand for sandblasting or other abrasives in order to conduct high-quality processing and not to spoil the device used.

- Differences abrasives

- Hardness

- Fraction

- Abrasive ability

- Mechanical stability

- Chemical resistance

- Types of abrasives

- Quartz sand

- Cooperslag and Nickel Slag

- Metal (technical) fraction

- Corundum

- Pomegranate sand

- What parameters should be considered when buying sand?

- Applications for abrasive materials

- Making abrasive at home

- Where to get sand for sandblasting?

- Sandblast consumption for sandblasting

- Calculation example of abrasive for metal processing per 1 square meter

- Preparing river sand for sandblasting

- How to sift sand for sandblasting?

- How to dry sand for sandblasting?

Differences abrasives

An abrasive is a hard material with a rough surface, used for abrasion and polishing of various substrates. Most abrasives are presented in the form of a fine powder, but some include larger particles with sharp edges. Despite the existence of different types of abrasives, they are all characterized by a common property: they have sufficient hardness, therefore they are able to clean contaminants from metal surfaces, concrete slabs and other materials.

Abrasive particles when used in a sandblasting machine are blown out by a powerful stream of air. The device gives them great kinetic energy, as a result, the existing plaque is quickly cleaned off. All abrasives are divided into:

- natural (sand, corundum, spar, diamond, chalk, iron ore, etc.);

- synthetic (cuproslag, borazon, boron carbide, etc.).

They differ in origin and composition, degree of hardness, mechanical and chemical resistance. The most popular and inexpensive is considered quartz sand for a sandblasting machine. Before it goes on sale, sand goes through several stages of processing, otherwise it can damage the equipment. Abrasives differ in particle size: for example, for delicate or damaged substrates, the most sparing materials must be chosen.

to contents ↑Hardness

All abrasives in hardness - the ability to resist the indentation of another material into them - are divided into:

- superhard;

- solid;

- soft.

to contents ↑Even soft materials can clean the dirt, but act more gently. The hardness index is set according to the developed Mohs mineralogical scale, dividing abrasives into 10 classes. Such a separation implies an increase in hardness as the class grows (the softest - talc - has class 1, the hardest - diamond - class 10).

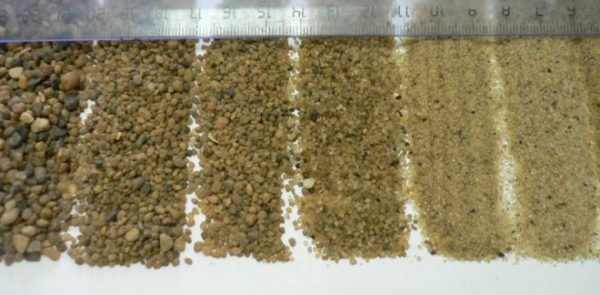

Fraction

Abrasive materials for grinding surfaces differ in grain size (size), depending on what they are assigned certain numbers:

- fine micropowders (M10 – M5);

- micropowders (M63 – M14);

- grinding powders (12–3);

- grinding grain (200–15).

In other words, abrasives are divided into coarse (large), medium, thin and especially thin ones by fraction. For their production, the main material is crushed by a press, resulting in crumb formation. It is sifted through special sieves, divided into powder with different grain sizes, single crystals or fragments. Usually abrasives of the largest fraction are used to clean materials from a thick layer of plaque, while fine ones are used for finishing polishing.

to contents ↑Abrasive ability

By abrasive ability is meant a time period for which it is realistic to clean a certain area of the product. This is the amount of material that can be sanded per unit of time. This property is highly dependent on the size, hardness, and other physical qualities of the crystals. Also, the abrasive ability is due to the intensity of the fracture of the particles into acute-angled elements during grinding.

to contents ↑Mechanical stability

Different types of abrasives differ in their uneven ability to withstand loads without destruction. Mechanical resistance depends on the compressive strength. The latter is detected during pressure on the crystal of abrasive material with a measurement of the load at the time of its destruction. For most abrasives, mechanical resistance decreases as the ambient temperature rises. The higher the resistance index, the more times the abrasive can be reused.

to contents ↑Chemical resistance

This property reflects the ability of abrasive materials not to change basic qualities under the influence of aggressive chemicals (acids, solvents, alkalis), as well as water.

to contents ↑Types of abrasives

When choosing sand for a sandblasting gun or another type of abrasive, you need to take into account the basic properties and characteristics of the latter in order to work with maximum efficiency.

Quartz sand

It is quartz sand that is the most demanded in the market for sandblasting and grinding products. It is characterized by low price, decent quality, is implemented everywhere. Quartz sand is made from white quartz by crushing it into different fractions:

- up to 0.1 mm;

- 0.10-0.4 mm;

- 0.5–1 mm;

- more than 1 mm.

The sand undergoes thorough screening, therefore larger particles are practically not found in its fine fractions, and sandblasting can be done without harm to the product. The material has good resistance and abrasion performance, especially considering its availability. Sand will not cause damage to delicate products, non-ferrous metals. Quartz sand waste after sandblasting can be implemented as a building material.

A significant minus of sand is the release of a large amount of dust, which enters the lungs, eyes of the worker, which is harmful to his health. With regular use of sand for such polishing in the absence of personal protective equipment, a deadly disease - silicosis can develop. To avoid such problems, all equipment should be equipped with dust extraction systems, and each batch of sand should be used no more than 1-2 times.

to contents ↑Cooperslag and Nickel Slag

These abrasive materials are obtained in the processing of slag of nickel and copper production. They are considered reusable, economical and more effective than quartz. Particle strength, hardness, and abrasion are higher for cooperslag than nickelslag. You can use such materials up to 3 times without the risk of dust.

to contents ↑The use of these abrasives is advisable when cleaning expensive and complex structures, which is associated with high quality results, but also with the price of materials. Kupershlak and nickelslag are able to clean the most durable types of metal and concrete; they are not crushed with plaque due to their high strength.

Metal (technical) fraction

This material is a small metal balls, which are made of steel or cast iron.Technical shot can be cast, chopped, chipped, and the first has a spherical shape, and the rest is acute-angled. Steel and cast iron shots are used for shot-blasting, shot-blasting processing of products that require notching (profiling) or descaling. This purpose is associated with high strength materials and the presence of acute-angled edges of their particles. After processing, the metal base will have a high degree of adhesion and adhere perfectly to the finish coatings.

Steel shot stands out for its good quality - it is the hardest, has the highest strength characteristics, can be used several times, does not cause dust. The increased operational resource is due to the additional heat treatment of the shot during its production. Corrosion-proof shot is used to process structures made of such materials:

- steel;

- zinc;

- titanium;

- aluminum;

- copper;

- bronze;

- brass;

- concrete;

- granite;

- marble.

Corundum

This material is prepared on the basis of aluminum oxide and is considered one of the most durable abrasives. Its particles have the shape of crystals, and in their characteristics are close to diamond. The price of the material is high, because it is used to process mostly expensive products. Corundum can be reused many times. It is ideal for decorative grinding and polishing surfaces.

A variety of corundum is electrocorundum - a heavy-duty material obtained by adding a number of impurities to alumina. Its particles are not damaged at all during the processing of materials, therefore repeated processing can be carried out a large number of times (after sieving). On the Mohs scale, electrocorundum is inferior to diamond in only one position, it is so hard. Its grains have sharp edges and have a unique ability to self-sharpen.

to contents ↑Pomegranate sand

Garnet, or pomegranate sand, is an abrasive of mineral origin, which surpasses silica sand, nickel slag, and cooper slag in technical characteristics. The material can be used repeatedly, it is used both for sandblasting and for hydraulic cutting of metal.

What parameters should be considered when buying sand?

An important condition for the acquisition of high-quality abrasive is the possibility of its reuse and the minimum amount of dust in the composition. For safety reasons, it is forbidden to use sand without personal protective equipment and special dust extraction, because when you hit the surface, the abrasive still breaks into dust. Therefore, in the absence of the possibility of carrying out work according to the standards, it will be necessary to give preference to another type of abrasive material.

To select the sand of the desired category, the following recommendations should be considered:

- Plaque thickness. The larger it is, the larger the fraction of sand should be. A dense, thick layer of rust can only be cleaned with a coarse abrasive - grinding grain.

- Base hardness. The harder the material of the product to be cleaned, the stronger the abrasive should be.

- Purpose of processing. When it is necessary to obtain a smooth surface even without minor defects, sand of the finest grinding is chosen. On the contrary, coarse grains will be required to apply a network of scratches and enhance adhesion with protective coatings. Usually, 0.6-1 mm sand is used to remove rust, while a larger one is suitable for removing thick bitumen coatings.

- The speed of the sandblasting machine. At high speed, the soft abrasive particles will quickly disintegrate and work efficiency will remain low. Also, at high speed, the use of particles of a rounded shape will be less effective than those that have sharp edges.

Applications for abrasive materials

The area of use of abrasives may vary depending on their type, strength, cost, fraction. For example, river or quartz sand is most often used to remove paint and varnish materials, rust, dirt from building facades, metal substrates. To polish products made of copper, aluminum and similar materials, quartz sand with a particle size of 0.1-0.3 mm is taken, to clean the metal from stubborn paint, it is better to take a sand fraction of 0.3-0.6 mm.

Old traces of rust that are poorly chemically removed are removed by sandblasting with 0.6–1.6 mm sand or nickel slag and kuperslag. The same abrasives can be used to remove welding scale from metal structures. Technical fraction is most often used for cleaning:

- small, medium, heavy casting;

- rolled carbon steel;

- products to be painted, plated;

- details of car bodies.

to contents ↑Also, the fraction during processing helps to strengthen the torsion shafts, coil springs, spring sheets. Electrocorundum, corundum is used to clean and polish titanium, alloy steel, tempered glass.

Making abrasive at home

In some cases, it is necessary to independently prepare a sandblasting feed mixture, for example, in order to save. Homemade abrasive is well suited for cleaning metal and concrete substrates. Typically, gravel or river sand is taken as the feedstock. The order of work is as follows:

- prepare 2-3 sieves made of fine mesh stretched on a wooden frame;

- sand is first sifted to remove debris, through a sieve with larger cells, then through small ones until an abrasive of the desired fraction is obtained;

- the finished material is dried in a metal container on a fire or in another way;

- sift the sand again through a sieve with the smallest cells.

Such sand can be poured into a sandblasting gun or apparatus of a different design and used as intended.

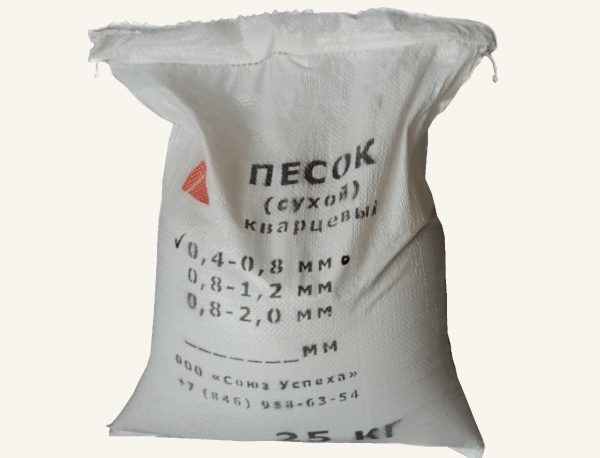

to contents ↑Where to get sand for sandblasting?

Sand is sold in any hardware store. On sale there is a packaged material in bags - ordinary without dividing into fractions or already peeled and sieved with the indication of the particle size on the package. Most often, quartz sand is sold in bags of 25 kg, its price per package is 250-300 rubles. Cleaned and fractionated river sand is cheaper (150–180 rubles per 25 kg), while non-seeded sand costs between 50–60 rubles per bag. For comparison, the cost of pomegranate sand is about 700 rubles / 25 kg, and electrocorundum - up to 2300 rubles for the same volume.

to contents ↑

Sandblast consumption for sandblasting

The consumption of abrasive varies greatly depending on the specific treatment and is due to the power of the sandblast, the amount of work, the fraction, the degree of contamination of the base, the size of the nozzle and other parameters. It is desirable to identify the expense indicator at the initial stage in order to calculate the total financial costs of all the work. The best choice would be an abrasive, which will have a minimum cost per unit area.

to contents ↑A good economic effect is provided by the use of sand for sandblasting, if its fraction is ideally suited for a particular type of work, and cleaning is carried out in a special box. The exact consumption can vary along with the source data (for example, with different thicknesses of the rust layer on one product), and the calculations will be approximate in any case.

Calculation example of abrasive for metal processing per 1 square meter

To understand which abrasive is best for processing, it is worth considering the average consumption of the most popular materials when cleaning metal to a degree of Sa 2½:

| Name of abrasive | Consumption, kg / sq. m |

|---|---|

| Quartz sand | 60–110 |

| Nickelslag | 35–80 |

| Kupershlak | 35–80 |

| Garnet | 3–7 |

| Electrocorundum | 3–10 |

| Technical fraction | 5–10 |

For a minute of processing a metal surface, an average of 2-3 kg of sand is spent. The consumption of this material can be slightly reduced using modern sandblasting machines with a closed treatment cycle, as well as vacuum systems for collecting spent abrasive.

to contents ↑If you remove old stubborn paint, a thick layer of rust, adhering dried cement, you will have to spend a lot of time cleaning the already used abrasive, which will have increased dust formation due to accelerated destruction.In such situations, it is worth considering the acquisition of another abrasive material with greater hardness.

Preparing river sand for sandblasting

As a preparation measure, sand should be dried well and sieved. Before loading into the sandblasting apparatus, it must be completely dry, otherwise the device may deteriorate. The permissible moisture level is determined by squeezing the material by hand - it should freely pour through your fingers. The sand fraction should ideally fit the size of the nozzle, which is achieved by sieving on sieves with cells of the right size.

to contents ↑How to sift sand for sandblasting?

To clean the sand at home, you can use improvised means - tulle, gauze, a sieve for flour, a mosquito net. The main thing is to sift the abrasive several times so that it is of high quality, is uniform in particle size and does not include impurities.

to contents ↑How to dry sand for sandblasting?

The easiest way is to dry the sand in a special drum dryer. The installation has a convenient drying chamber and an integrated sieve, so the time and effort required to prepare the abrasive will be minimal. In the absence of such a device, you can dry the sand above the flame of a fire. For this, a sheet of metal, an iron box, another metal container, where the sand will be located, is fixed over the fire. Some craftsmen dry the material with a heat gun, sprinkling it on a film. It is convenient and easy to do this, and the quality of the finished abrasive will be at a decent level.