In construction stores, various tools for cleaning surfaces of metal, wood, concrete are sold. The most effective of them is sandblasting - a device for cold abrasive processing of various materials using sand.

- The principle of operation and the purpose of the sandblasting apparatus

- Design Features

- Accessories

- Which compressor to choose for a home-made sandblasting installation

- Sandblasting chamber

- How to make do-it-yourself sandblasting

- Nozzle installation

- Adapter mounting

- Hatchet blank cutting

- Creating a tank from a bottle

- Abrasive backfill

- Product Check

- Alternative sandblasting techniques

- From a high pressure washer

- From a purge gun

- From a spray gun

- From a gas bottle

- From a fire extinguisher

- Pros and cons of homemade sandblasting

- Instructions for the proper use of the device

- Recommendations of specialists

A good installation is expensive, so many craftsmen prefer to make a sandblasting machine with their own hands. The cost of such a device will be low compared to store sandblasting.

to contents ↑The principle of operation and the purpose of the sandblasting apparatus

A sandblasting gun or other type of abrasive blasting device, bought at a low price, most often does not last long. The main parts of a cheap design quickly deteriorate, wear out, because of which the apparatus becomes unusable. In order to save on the purchase of a high-quality device, you can use a homemade gun that works on the same principle as a store gun.

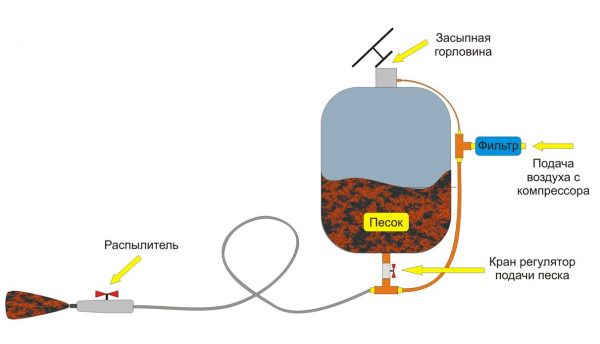

Abrasive material (most often ordinary fine sand), under the action of air from the stream created by the compressor, moves through a reinforced hose to the installation opening. It is fed through the nozzle directly to the surface to be treated. Due to the high pressure, sand moves, its particles act with high energy and clean any pollution. The installation itself, on the one hand, is connected to a compressor, and on the other, to a separate sand bunker using special hoses.

In addition to cleaning surfaces from dirt, a sandblasting gun performs a number of other tasks:

- removal of old coatings;

- elimination of traces of corrosion;

- frosting glass;

- degreasing of surfaces.

to contents ↑When using the device, it is important to pay attention to the quality of the sand. It should be small, clean, sifted through a sieve with the smallest cells. When using contaminated coarse sand, the nozzle of the device becomes clogged and the gun breaks.

Design Features

In order for the technical system to function properly, it includes the following devices:

- sand nozzle with ceramic or steel tip;

- handle with a trigger to control the device;

- fittings for connecting hoses necessary for supplying compressed air and sand;

- hoses for incoming abrasive and forced air;

- intake pipe or suction valve;

- a sand container with an outlet (for example, a small metal barrel or bottle).

The ideal option is to use home-made sandblasting not in the open air, but in a special chamber, which will increase work efficiency and reduce the consumption of abrasive. The camera can serve as a box of metal sheets, which are welded independently. Most factory camera models include these items:

- glass inspection window for monitoring the processing of materials;

- lighting system;

- two holes for gloves in which the master puts his hands;

- a grill at the bottom of the chamber and a chute for pouring waste sand;

- ventilation system to remove dust.

to contents ↑It is better to purchase the nozzle in finished form, rather than to make it yourself, so it will last longer. Manually making a nozzle of decent quality is almost impossible. The compressor will also have to buy, or take the old device that is available.

Accessories

In addition to the compressor and nozzle, before making a sandblast, you need to prepare other necessary materials and tools. Most of them are in every home workshop, but some will have to be purchased at a hardware or hardware store.

As a container for abrasive suitable exhaust gas cylinder, the material of which is made of high strength metal. The tightness of the balloon also allows its use for storage and supply of sand. To pour sand was more convenient, a piece of a small pipe can be welded to the upper part of the container, which will serve as a “neck”. Instead of the cylinder, you can use any barrels, containers.

If buying a ready-made compressor causes financial difficulties, you can build it yourself. The basis will be the compressor head from the MAZ or ZIL pneumatic drive, the power of which is enough to create a good sandblast. The head should be equipped with a receiver, although you can work without it - then the air will be taken in constant mode.

Depending on the complexity of the finished design, other components may be required:

- Ball Valves;

- rubber hose with reinforced inserts with a diameter of 14 mm or more;

- air hose with a diameter up to 10 mm;

- hose fittings or collet clamps;

- adapter sleeve;

- FUM tape for sealing and connecting elements;

- 0.5 liter empty plastic bottle;

- glue gun and hot glue;

- grinder or file, sandpaper with a bar;

- drill with drills;

- sharp knife;

- Bulgarian;

- pliers.

Which compressor to choose for a home-made sandblasting installation

It is desirable that the compressor performance is at least 300 liters / minute, power - from 3 kW, air pressure - 6-7 atmospheres, there is protection against overheating. For domestic purposes, a device that works from a network with a voltage of 220 V. is suitable. If the compressor has a receiver, it will help to avoid pressure drops when switching to different operating modes.

When the compressor is purchased ready-made, you need to pay attention to the type of equipment:

- Pressure type compressor. Abrasive material is fed into the system under the influence of compressed air and its own mass. Compressors of this type are considered professional, they are distinguished by high performance. With their help they process surfaces of a large area - bridges, buildings, ships, railway cars, complex structures. For domestic use, pressure compressors are not practical.

- Injection type compressor. Such devices work due to the pressure created by the air flow, which moves the sand inside the system. They are much cheaper, because they are well suited for a small amount of work in the domestic environment.

Sandblasting chamber

To reduce the consumption of sand, which scatters to the sides and is significantly spent, you can use a special camera. It is not difficult to do it yourself, although it will require time and financial costs. It is necessary to weld metal sheets in the form of a box, install glass in the body to visualize the process.2 holes are drilled in front, to which 2 coarse fixed gloves are attached. The bottom is made of thick wire or grate, and underneath is a plastic or metal gutter to divert the abrasive. The sandblasting gun is installed inside the camera, which is most conveniently placed on the table.

to contents ↑How to make do-it-yourself sandblasting

In action, a home-made sandblasting apparatus behaves no worse than a purchased one if it is designed correctly. Below is a way to create a simple mini pistol.

Nozzle installation

It is necessary to purchase a ready-made sprayer with a nozzle. If the kit contains two nozzles of different sizes, you need to take what is larger.

Adapter mounting

For proper operation of the sprayer, an adapter must be installed from the external thread to the internal thread. Typically, a 1 cm adapter sleeve is suitable for this purpose, which must be wrapped clockwise with an FUM tape to seal. Next, tighten the clutch using pliers.

to contents ↑Hatchet blank cutting

To save abrasive, you can cut the nozzle 0.5-1 cm long using a grinding machine with a cutting disc. For convenience, it is recommended to clamp the nozzle in a vice.

Creating a tank from a bottle

Take a 0.5 liter bottle from plastic, cut off the ring from the cap with a knife, remove it. Drill a hole at the location of this ring through, taking a drill by 3 mm, and then expand the hole with a drill by 4.8 mm. The bottle should also be kept in a vise.

Abrasive backfill

Fill the bottle with sand or another abrasive (e.g. glass). This should be done by placing a funnel of plastic or a sheet of paper on the bottle. After you need to enter the nozzle into the drilled holes, glue it with hot-melt adhesive.

Product Check

As the nozzle is ready, the mini-gun is connected to the compressor. For verification, a low pressure indicator is set and testing is carried out on any old, dirty or painted part. Be sure to use a respirator, goggles, durable clothing, so as not to harm your health when working with sandblasting.

to contents ↑Alternative sandblasting techniques

There are different options for creating sandblasting, which can be used in a home workshop.

From a high pressure washer

The device for cleaning sand can be built from a minisink like “Karcher” or a device of a different brand. A car wash creates a lot of water pressure at a low flow rate, so it’s great for making a machine. It is important to use the finest sand of uniform dispersion, for example, well sifted river.

To make a sandblast, you need to assemble a nozzle for the outlet tube of a car wash. You should buy these components:

- ceramic nozzle;

- reinforced hoses;

- cylinder type dispenser;

- mixing unit (tee of the desired diameter).

Instead of air, water will be responsible for the supply of sand in this sandblasting machine. Liquid under pressure will pass through the mixing unit, create a vacuum in the abrasive supply hose. As a result, sand will begin to be thrown out with great force and perform grinding, polishing, cleaning, and matting of surfaces.

to contents ↑From a purge gun

Such a device works quite efficiently, small in size and economical in price. A sand feeder made from a blow gun is ideal for small bodywork and a variety of domestic purposes. The performance of the device will depend on the type of compressor, its power. In addition to the purge gun itself and the compressor, for work you will need:

- plumbing tee;

- ball valve for regulating the flow of sand;

- output nozzle with clamping nut;

- plastic bottle as a container for sand.

to contents ↑After connecting the parts, you need to connect the gun to the compressor and conduct a test sandblast cleaning, having previously poured sand into the bottle and adjusting the intensity of work with the trigger.

From a spray gun

To create a sandblast of this type, you need a simple spray gun, as well as:

- ball valve regulator;

- plumbing tee;

- reinforced hoses;

- compressor.

to contents ↑To assemble the device, it is necessary to grind the spray gun under the nozzle of the required size, install two hoses (for air circulation and abrasive supply) and connect the compressor. Start sand feed will be carried out with a simple pull of the trigger gun.

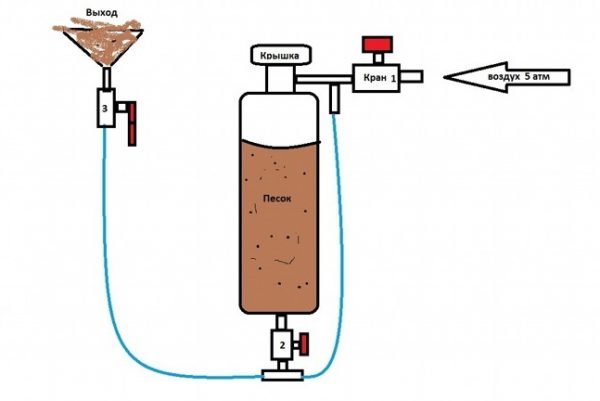

From a gas bottle

Pressure blasting from a cylinder type is one of the simplest but most reliable structures that can be made independently. It is necessary to prepare such components:

- ball valves - 2 pieces;

- small gas cylinder;

- pipe to create a funnel on the container;

- plumbing tee;

- sleeves 14 and 10 mm for supplying air and sand and fittings to them;

- hose clamps;

- FUM tape.

All contents are removed from the container, cleaned from the inside using suitable detergents.. The cylinder is cut off from above by a grinder in accordance with the diameter of the purchased pipe. Below make another hole for connecting to the crane.

The next step is to install a crane by welding the regulator or by screwing it through an adapter tube. Connect a tee, a mixing block, seal the thread with an FUM tape. A tap is placed on the cylinder valve, then a tee. For the convenience of moving the apparatus, wheels are welded, and to improve stability, supports from corners, reinforcement.

to contents ↑At the end of the work, pipes for supplying air and sand are connected - fittings are placed on the tee and valve of the gas cylinder, while having a 14 mm sleeve between the mixing block and the tee. The compressor is connected to a free branch of the tee, and a sand hose is mounted on the third end.

From a fire extinguisher

This installation is assembled similarly to a fire extinguisher. To seal the upper part, you need to create a cap in advance using lathes. Put on the rubber seal ring on the plug and screw it into the neck of the fire extinguisher. This hole is suitable for falling asleep sand. Next, you need to drill holes on the case at the top and in the bottom, having previously cleaned these areas from old paint. At the bottom, you can weld the legs of pipes, fittings. After installing the tees and hoses, you can use the sandblast for its intended purpose.

to contents ↑Pros and cons of homemade sandblasting

The main advantage of making the device with your own hands is significant savings, since the cost of all parts individually will still be lower than the price of a finished sandblasting machine. If desired, you can create a fairly powerful unit, which depends on the type of compressor. Self-manufacturing sandblasting also has disadvantages:

- the need for welding skills;

- the need for quality components;

- difficulties with repair in the event of a breakdown (most often it is necessary to replace one or another node);

- risk of injury if assembly rules are not followed.

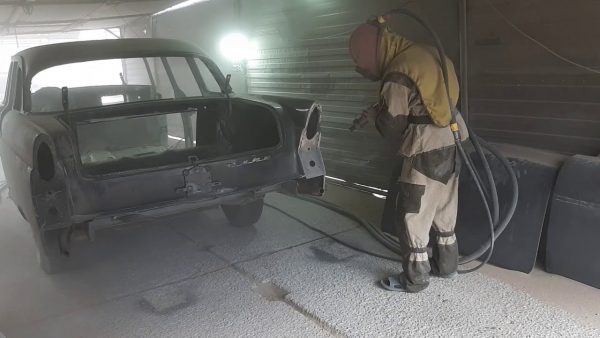

Instructions for the proper use of the device

In order not to injure yourself and not break the unit, you need to work with it carefully, in compliance with a number of norms and rules. Be sure to wear a respirator, goggles so that sand and metal particles, paints do not get into your eyes, respiratory tract. Before each use of the sandblasting device, it is important to check the integrity and correctness of the connection of the main nodes, the tightness of the joints. Other tips are:

- always open the sand supply valve before turning on the compressor;

- it is necessary to regularly inspect the nozzle for the strength of its fastening and the absence of damage;

- a stream of sand should be directed at an angle of 90 degrees to the base - so the effect of grinding will be higher;

- the device’s hoses should not be stretched when working with it, this should be constantly monitored;

- sand of low quality or large fractions is capable of damaging the apparatus, similarly wet abrasive material acts on the device;

- To exclude electric shock, it is necessary to ground the compressor of the sandblasting apparatus.

Recommendations of specialists

Most of the problems that arise are related to improper installation. Experienced craftsmen advise to include air recirculation devices in the system, which seriously increases the productivity of sandblasting. Also, the quality of the finished device will improve the correctly selected nozzle. Tungsten nozzles that have a long service life are ideal.

As for the compressor, you can take any device lying around in the garage, but more powerful installations will increase work efficiency. A home-made compressor will save money and make carrying out various works easy and affordable, reducing time costs.