With prolonged contact of the steel with moisture or air, a layer of iron oxide forms on the surface. At the same time, the product loses its visual appeal, but this is not the only unpleasant consequence. In the future, the metal will begin to rust rapidly, as a result of which the subject may lose its basic functions. The rust removal laser is a modern method of cleaning metal surfaces, which has become a more effective alternative to chemical methods of stopping corrosion.

- Laser cleaning technology

- Laser ablation

- Desorption

- Laser Cleaning Equipment

- The advantages of the method

- Scope of use

- Microapplication

- Macro application

- Large-scale use

- What laser models are available?

- Chinese lasers

Laser cleaning technology

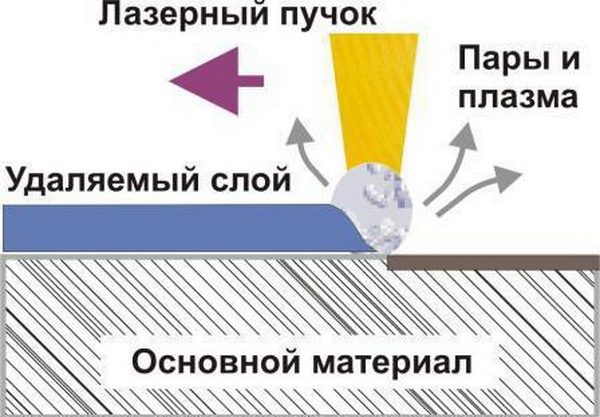

In order to conduct laser cleaning of metal from rust, you need a special apparatus that focuses a powerful light flux. The principle of operation of the device is the ability of a pure metal to reflect laser radiation when substances with a more complex composition absorb it. As a result, a layer of rust, which includes a mixture of three iron oxides, hydroxide films and various contaminants, begins to accumulate energy, heat up and peel off from the base. If the power of the laser equipment is high, then the plaque melts and evaporates.

to contents ↑Laser ablation

Most often, laser cleaning of metal from rust is carried out using ablation - pulsed radiation, causing the evaporation of the oxide film. The latter "rises" above the surface in the form of a plasma cloud, then resolves. Ablation occurs at the border of two phases: gaseous and condensed - and begins due to a sharp temperature drop (equipment can heat the base to +16500 degrees).

The order of operation of the device is as follows:

- Scanning (diagnostics). The laser determines the depth of processing using a short pulse emitted by the working head.

- The main stage. In automatic mode, power is selected, complete rust removal is carried out.

Desorption

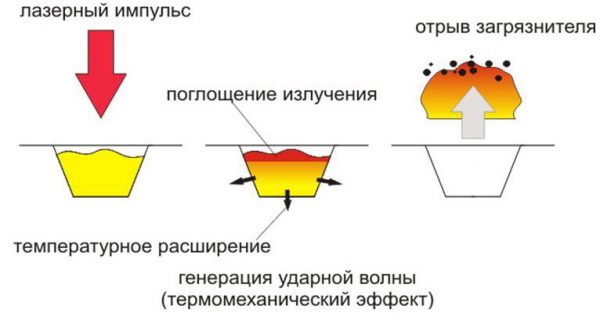

Desorption is understood to mean a conditionally milder effect on rust by a photon beam, which causes separation of the surface layer in the form of flakes. Such plants are characterized by low power, leading to heating without phase transformations. Typically, to achieve the desired effect with an oxide film thickness of 50-75 microns, the thermal energy density should not be less than 106 W / sq. cm, the diameter of the ion-photon beam is up to 100 microns.

In addition to heating, the presence of the shock force of the emitted light beam accelerates the achievement of the result. Laser desorption due to the sparing effect on metals can be used on products with:

- decorative finish;

- corrugation;

- various grooves, holes;

- intricate details.

Laser Cleaning Equipment

All mechanisms for laser metal cleaning are automated as much as possible, while human efforts are reduced to a minimum. Laser machines differ in power, type of construction, size, some of them are equipped with a camera with remote control, which is connected to a computer. For processing large aggregates, laser systems are equipped with long cables (from 50 meters).

By the power of the device can be as follows:

- for small areas - 12-20 W (small laser on batteries);

- for medium areas - 100-400 W (portable systems of compact size);

- powerful installations - up to 1000 W (portable and stationary devices).

to contents ↑Typically, such tools can work against rust or for other purposes without replacing the working head within 100,000 hours. After the part must be replaced in order to continue to operate the device. Laser systems are safe for humans; they are equipped with special protection against the beam coming out of the workpiece.

The advantages of the method

The laser is used as a rust remover everywhere, both in large industrial enterprises and in small car services. With the help of small low-power battery packs, it is quite possible to clean the metal from corrosion elements with your own hands in an ordinary garage. Other advantages of the laser method compared to the use of cleaners, converters and mechanical cleaning methods are as follows:

- lack of harmful emissions, safety;

- lack of human contact with the treated surface;

- the highest quality and accuracy of cleaning;

- noiselessness of even the most powerful installations;

- high speed surface treatment;

- ease of setup and adjustment of the device;

- automatic shutdown of the laser emitter after the completion of the process;

- the ability to work with many metals and alloys;

- lack of need for expendables;

- no danger of material damage, uniformity of the removed layer.

to contents ↑

Scope of use

The laser has a wide range of applications, while it distinguishes between micro-, macrozone and large-scale operation. The costs of the treatments will also be different, because they depend on how much the installation itself costs, on its capacity, scope of work and their complexity.

Microapplication

This area of use involves stripping wires during poultry, welding various electronic connections - terminals, connectors. Other than laser, it is almost impossible to clean small flat wires from old insulation without damaging them. The light beam will remove the insulation layer with a thickness of less than 1 micron or a sprayed silver coating, without touching the copper component. In addition, in the field of electronics, laser is used to perform:

- thin incisions;

- holes in the wires;

- notches on the boards.

to contents ↑If necessary, with the help of laser systems it is possible to remove the polyamide coating from brake or cooling systems, which is required when cleaning the ends of the connected tubes. The laser technique will allow this complex operation to be performed without damaging the aluminum core.

Macro application

Laser metal cleaning is an expensive method, but it is fully justified if necessary in the processing of expensive products: jewelry, coins, ingots, valuable items. This technology is also used in the production of rubber products at factories: a light beam effectively removes plaque from tire molds after hundreds of fillings. If you clean the molds by the chemical method, the process will take a long time, and the surface of an expensive product may be damaged.

The laser prevents such effects and minimizes the time required to remove corrosion elements. The laser processing time for the mold does not exceed 60 minutes compared to the 8 hours that the chemical method requires. Also, the product will not need to be dismantled before work, which is much more convenient technically and eliminates problems during reassembly.

to contents ↑Large-scale use

Laser rust cleaning is practiced in the production of components for aircraft, spacecraft, etc.Since the 90s, many military and passenger aircraft have been cleaned of paint, plaque as part of maintenance with a laser. Such installations are used to remove old lead paints from the hulls of ships, bridges, other large-sized structures, railway cars, buildings.

to contents ↑What laser models are available?

The most popular on the market are the devices of the company Clean Laser (Germany), which produces a large line of laser equipment. The most popular is considered a compact “backpack” laser, consisting of 3 separate modules, which are connected by a fiber optic cable:

- satchel with a power source;

- laser head;

- video surveillance device.

When the unit is turned on, the surface is scanned, the depth of rust is detected, and only then the full-power laser stream is directed to the area of contamination. The remains of the destroyed rust elements that are disconnected from the metal are carried away into a special container. The process ends automatically when the surface of the product becomes completely free, and the light stream directed at it will be reflected.

Small battery packs of low power are very popular with archaeologists, antiques lovers, as they allow you to remove pollution from even delicate, valuable objects. Units of medium size with a capacity of up to 400 W look like compressors and are usually used in car repair shops and small production facilities. Dimensional, powerful installations are of large-scale importance and cost hundreds of thousands of dollars.

to contents ↑Chinese lasers

Chinese-made products are also in demand in the market, because their price is usually cheaper than European installations. For example, the apparatus LY CL 100 is used to clean rust from metal products, has a power of 100 W, and is operated without changing the head for 50,000 hours. Here are the other characteristics of the device:

- repeat frequency - 1.2-25 KHz;

- work speed - 7000 mm / s;

- linear speed - 70 m / min;

- wavelength - 1064 Nm;

- installation weight - 70 kg.

Such mobile devices can be used to clean the body of a car, remove paint or clean rusted areas. The use of a laser is considered an effective and safe way to update parts, helps to extend their life and seriously save on buying new ones.