Plywood, like many other materials, can be putty. However, it is important to choose the right putty mixture. Putty for plywood should have special qualities, the most important of which is water-repellent properties. This article will discuss the features of processing plywood and choosing the right composition for these purposes.

- Plywood properties

- Putty goals

- Varieties of mixtures

- Impregnation with drying oil or PVA

- Padding

- Puttying

Plywood properties

The classification of plywood involves the separation of grades, mechanical characteristics, elasticity and resistance to moisture. A letter marking of the material is developed, which necessarily indicates the type of glue used for impregnating and fixing veneer in the manufacture of the product.

Characteristics of plywood:

- In the Russian Federation, standards provide for the manufacture of plywood in the following sizes (in millimeters): 1525x1525, 1220x2440, 2440x1220, 1250x2500, 2500x1250, 1500x3000, 3000x1500, 1525x3050 and 3050x1525. The thickness of plywood sheets can vary between 3 and 30 millimeters.

- For the production of plywood, birch or coniferous wood (pine, spruce, larch) is used. The veneer is glued together perpendicular to the arrangement of wood fibers.

- Each type of product is assigned a specific marking: FSF, FBA, FSF-TV, FB, FC, BS and BV.

- The following grades are suitable for puttying: FSF, FSF-TV, FC, FB and BS. The fact is that these products are characterized by increased moisture resistance, which is an indispensable condition for the selection of material suitable for puttying.

- Plywood is also classified by degree of processing. Laminated and non-laminated varieties are available. Products polished on one side are marked as Ш1. Double-sided grinding is reflected in the marking Ш2. If the plate was not polished at all, it is marked as NS. Of all the varieties listed, non-laminated and unpolished plywood is most suitable for puttying.

Putty goals

Plywood structures are often used to level different types of surfaces during repair work. Installation of plywood sheets is carried out on the floor, walls and ceiling. However, without additional procedures, the seams between the end-to-end sheets do not look very attractive, and the surface of the material itself is not even enough to lay linoleum on top or glue the wallpaper. It is puttying that allows you to create a perfectly flat surface and hide interpanel defects.

It would seem that puttying is an obvious way out. However, many masters wonder: is it possible to putty plywood, because we are talking about wood? The fact is that such doubts have a basis, since humidity provokes rotting of wood, the development of mold and fungus on it, which gradually leads to the destruction of the material.

There is a way out if not the first putty that comes across is used for processing, but a special one - made taking into account the characteristics of the wood. With the help of such compositions, you can eliminate all the problems inherent in plywood sheets, and at the same time not damage the material. The putty contains moisture protective agents, which makes it possible to produce mixtures even on a water basis. In addition, thanks to the addition of an antiseptic, the putty is also able to withstand the development of fungus and mold.

to contents ↑Varieties of mixtures

For the correct choice of putty composition is important for a number of factors. The surface requirements before wallpapering differ from the requirements before painting, since in the latter case, the composition should have a more delicate effect on the surface. In addition, it is necessary to take into account the humidity in the room and temperature changes (for example, cement putty does not tolerate sudden changes in temperature).

Putties are sold in one of two states:

- powdery;

- in finished form (viscous solution).

Most often, dry putties are used to process plywood. Such compositions are more convenient in transportation, and their consistency can be adjusted during kneading to the desired degree of viscosity. Dry mixes are packaged in bags of different capacities.

Ready-to-use solutions are also produced. The basis of such mixtures are a variety of dispersions, as well as polymers in the form of latex or silicone. Polymeric materials have a number of significant advantages, which will be described in more detail below. The main advantage of the finished formulations is their complete readiness, since there is no need for time and labor for preparing the mixture. The disadvantage of ready-made solutions is a significantly higher cost in comparison with powders.

Answering the question of how to putty plywood, it should be said that the main differences between different putties are in the base material.

To putty the plywood, mixtures based on the following components can be used:

- gypsum;

- polymers;

- cement;

- glue.

Below we will tell a little more about the different types of putty:

- Gypsum mixtures are characterized by the simplicity of their composition and the absence of shrinkage. However, this type of putty is not flexible enough, as a result of which there is a risk of cracking at the seams due to insufficiently reliable fixing of plywood sheets. The disadvantages of gypsum putty can also include a rather high cost and frequently found marriage.

- Cement mixtures are characterized by a sufficiently high moisture resistance. A significant disadvantage of cement is its tendency to shrink and lack of elasticity. Especially explicitly listed negative qualities are manifested during heat and sharp temperature drops.

- Polymer-based putties are most suitable for working with wood. Polymer compositions are highly moisture resistant, and therefore plywood treated with such fillers can be used even in wet rooms. The polymers do not shrink, have the highest elasticity, resistance to vibration and mechanical stress. All polymer putties are sold only in finished form (packaged in containers weighing from 3 to 20 kilograms). There are two types of polymer compositions: based on acrylic (silicone) and latex. Putties of this group are also divided by scope: for interior decoration and for processing facades. The only significant drawback of using polymer compositions is the high cost of their acquisition.

- Glue putty - the result of home-made production at home. Such a composition is prepared by mixing in a certain proportion of PVA glue with chopped wood dust. Adhesive compounds are characterized by high moisture resistance and elasticity. The advantage of self-manufacturing is the ability to bring the solution to the desired consistency. In addition, the cost of this composition is significantly lower compared to the putty factory production.

Impregnation with drying oil or PVA

Before laying linoleum on plywood, it is recommended to improve the base properties in advance. Putty of plywood under linoleum is carried out by impregnating the material with linseed oil or PVA. The impregnation process requires a certain time (usually several days), since the technology provides for the complete drying of all layers impregnated sequentially one after another. In addition, drying is in no way forced and occurs under natural conditions.

Note! PVA is applied to plywood without forced acceleration.

When plywood is saturated with PVA and dried, it is the turn of an antiseptic, the processing of which helps prevent the development of fungus and mold. Further, the material is covered with acrylic varnish.

Another option for strengthening plywood before puttying and further laying linoleum is to impregnate veneer with warmed drying oil. With the help of a water bath, the drying oil is heated to 50-60 degrees Celsius (in no case should the temperature be exceeded). Heated drying oil is applied to the surface of the material with a roller or brush. Further, the plywood dries at 200 degrees above zero or under the influence of a building hair dryer. The procedure is repeated again and again - as long as the plywood retains the ability to absorb drying oil. Impregnation can be stopped as soon as large drops of drying oil begin to linger on the plywood.

Note! When impregnating, special attention should be paid to the end sections of the sheets, since it is precisely these places that are most vulnerable to external influences.

to contents ↑Padding

When plywood is laid on the floor, it must be primed. Unlike the impregnations discussed above, which are aimed at protecting against decay, the primer is considered as a way to improve the quality of putty. The fact is that priming can improve the adhesion quality of the surface (adhesion is the ability to adhere to dissimilar materials). In addition, the primer forms a protective barrier against too deep penetration of paint and varnish compositions into the wood structure.

Note! Puttying is allowed only after the primer has completely dried.

As in the case with putties, specialized primers are used for priming, designed specifically for wood processing. A feature of such formulations is the presence in them of special components, including antiseptics.

So, before you putty the plywood, it must be primed. Previously, the material is cleaned of dust, dirt, oil stains and any other contaminants. It is possible to apply soil only on pure natural veneer.

Next, a primer is applied to the plywood, for which you can use a brush or roller. After this, let the surface dry. Drying time depends on humidity and room temperature. On average, it will take 3 to 6 hours to dry.

to contents ↑Puttying

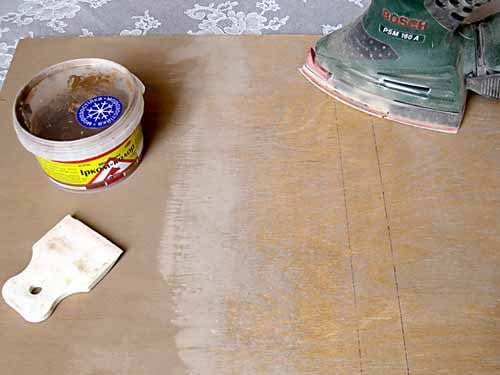

Putty application on plywood is carried out according to the same principle as on concrete or brick. As a tool you will need a spatula, a rule and a malka. Particular attention should be paid to the joints (the Fugenfüller is used for this). The normal thickness of the putty layer is 2-3 millimeters.

If small grains remain on the coating after the putty is finished, they should be removed with sandpaper as soon as the surface dries. However, this development of events can be prevented if the solution is previously sieved through a fine sieve or nylon. Once the surface is completely dry, you can proceed with further finishing work.

Puttying with plywood is not much different from processing other materials. However, it must be remembered that any wood is vulnerable to humidity, and therefore needs protective measures, which we described in our article.