Putty Shitrok is considered universal, this material is a ready-made mixture for wall decoration. The tool is easy to use - it is easy to apply, and the result is always excellent.

- From Sheetrock to Danogips

- Material Features

- Material characteristics

- Advantages and disadvantages

- Product range

- Danogips SuperFinish

- Danogips Fill & Finish Light

- Danogips ProSpray

- Application Technique

- Material consumption

- Sheetrock, Knauf Rothband Paste or Vetonit LR - which is better

From Sheetrock to Danogips

The Danogips brand (Danogips) belongs to the Danogips company. In Germany, everyone knows this brand of construction and decoration products, but in the domestic market this name is a novelty. The manufacturer produces dry and ready-made mixtures, primers, gypsum boards. The quality of the goods is very good, while the prices are quite economical.

Finished putty Sheetrock (Shitrok) also belongs to the Danogips brand, they went through a design change with a package update. In the CIS countries, up to 1/3 of the entire market for ready-made putties for walls is occupied by Shitrok. Now on sale there is a line of three products, called the umbrella brand Danogips, but retaining the composition and properties of Sheetrock.

to contents ↑Material Features

Putties are suitable for all occasions, therefore they are considered universal. Their main purpose is the alignment of walls made of concrete, drywall, brick before finishing-painting, wallpapering. The description of the material indicates that it has high ductility. Indeed, the polymer finishing putty of Shitrok has a number of advantageous features. They are due to the unique composition, which includes:

- finely ground limestone;

- fine dolomite;

- ethylene-vinyl or acetate-vinyl copolymer;

- pyrophyllitis and attapulgite.

The latter materials give a dry slip effect. This helps to easily putty the walls on a dry surface. Of course, there are other components in the composition - substances that do not allow the mixture to delaminate, preservatives, thickeners, stabilizers. Also, to give airiness to the mass, special cellulose microfiber is used. Due to its presence, the product becomes like a whipped cream. The same component provides high layer strength after putty. Polyhydric alcohol is added to the composition, which prevents fungus and mold from multiplying.

Features of the material are as follows:

- well fixed to the wall;

- does not fall off the spatula;

- perfectly flat after drying;

- beautiful white or cream color;

- the mass dries quickly;

- the material is moisture resistant, but quite breathable.

In addition to puttying drywall or other surfaces, the material is also suitable for other purposes. Cheetrok is suitable for removing cracks, defects on walls made of concrete, brick, with plaster. Putty can seal any seam between the sheets of drywall on the walls, ceiling and partitions, and put on top of the connecting tape. With the help of Shitrok, corners are processed, metal surfaces are finished. With Shitrok you can create a beautiful decorative surface with a certain relief.

to contents ↑Material characteristics

Technical characteristics of the material allow it to maintain leadership in the market for similar products. Here are its main parameters:

- drying time - 3-5 hours;

- ways to work with the mass - manual, mechanized;

- material application temperature - from +13 degrees;

- density - 1.65 kg / l;

- filling volume - sold in buckets of 3.5-17 liters.

to contents ↑The high density of the product can scare, because grinding the material is the more difficult the denser it is. But this does not apply to the Shitrok brand. Grinding the dried putty mass is very simple, for this purpose a mesh with a grain of 180 units is used.

Advantages and disadvantages

Which is better, Puttyro putty or other mixtures? This tool has a huge number of advantages that distinguish it from its analogues:

- You do not need to mix the tool, it is implemented in finished form. After opening, you can immediately start work, which will save time, effort.

- The material is universal, it is suitable for leveling walls and finishing. You do not have to buy another finish.

- The tool has a unique texture. The oiliness, smoothness, plasticity of the putty allows it to adhere perfectly to the spatula and wall. This greatly facilitates the work for the beginner. Ease of use is also due to the ease of rubbing and filling of the layer.

- The rather low consumption per 1 m2 of putty makes it attractive for those who value the calculation and try to save without loss in quality. Savings are due to the insignificant thickness of the layer, there is no need for a thick coating.

- The material is sold in containers of different volumes, you can choose the right one in each individual case.

- After drying, the surface will be very beautiful, smooth, pleasant to the touch, soil can be easily applied to it. The material does not shrink, the manufacturer guarantees a minimum of 5 years with the absence of even small cracks.

- Cheetrok will completely replace the primer. To do this, it just needs to be diluted with water to a liquid consistency, then used as a standard soil. Shitrok is also compatible with any brands of other building and finishing materials.

- The shelf life of the package after opening is several months. If you close the lid tightly and put the material away from heat sources, storage is allowed for a year. By the way, it can be frozen, for further use you need to defrost at room temperature.

Shitrok has not a lot of disadvantages. After applying to the wall, the shade of the material becomes not white, but light beige. This can adversely affect the color of the walls that are planned to be painted white. The disadvantages include the need for thorough surface preparation - it must be cleaned, degreased, evened out in the presence of gross irregularities and defects. If this is not done, the adhesion of the Shitrok with the base will decrease.

to contents ↑Product range

There are three products in the Ready-Mixed category. Among them, users can find one that is useful in a particular situation, depending on the purpose of use.

Danogips SuperFinish

The putty of the Superfinish category is a finishing material for the final decoration of the wall. Super finish - ready-made polymer mass with high adhesion quality, which is suitable for such surfaces:

- fiberglass;

- drywall;

- painted walls.

The tool is not suitable for closing large cracks, seams. Superfinish gives a perfectly smooth surface.

to contents ↑Danogips Fill & Finish Light

Fill Light putty is also used as a topcoat. It is suitable for laminating the substrate, for leveling small defects. The composition introduced latex, which gives the material special strength, scratch resistance, moisture resistance.

Danogips ProSpray

Danogypsum Pro spray is a multifunctional (universal) product that is suitable for every surface and any type of finish. They can make decorative surfaces, apply for sealing joints and cracks, align the joints of brickwork.

to contents ↑Application Technique

How to work with the material? There are no particular difficulties and differences from working with other putties. It is only important to prepare the surface for processing, while the humidity in the room should be minimal. To prepare, do the following:

- clean the walls of the old coating;

- level differences of more than 2 cm;

- make a primer.

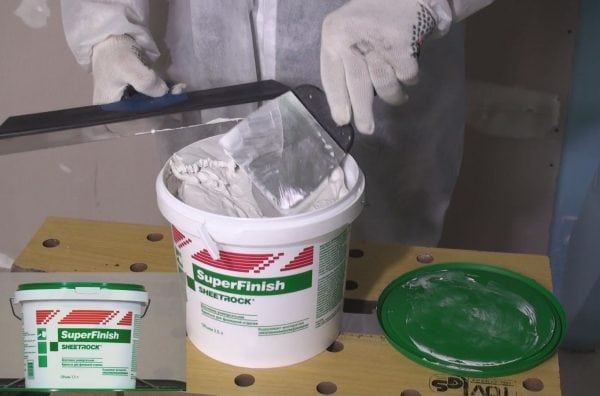

After complete drying, you can begin to work with Shitrok. From the bucket take a little material, place in a convenient container, put on the floor or on a stand. Putty putty is taken with a spatula, applied to the wall in one thin layer. The thickness of the layer is 1-2 mm. After covering the entire wall, you need to take a break to dry - 3-5 hours. Then you can do the grinding. The consumption for fiberglass is higher, since 3 layers must be applied, in other cases 2 layers are sufficient.

There are some features in the application of putty in different ways. When finishing joints, the work is done as follows:

- take a spatula 12 cm, fill the seams with it using the finished mixture;

- put the tape in the center, push it in;

- remove the mass that has crawled out at the edges, apply it a little on top of the tape;

- close up the fastener heads with material (if necessary);

- after 3 hours, apply a second coat, sand as it dries.

to contents ↑When finishing the internal corners, putty is applied on 2 sides of the tape with a 12-centimeter putty knife. Then the tape is folded in the center, pressed to the corner with a spatula, the excess mass is removed. After drying, repeat the action 2 more times. At the end of the work, wipe the surface with a damp sponge.

Material consumption

Before starting work, it is important to use the calculator to calculate the required amount of material. Standard consumption - liter per 1 sq. M. It is spent more on the joints of drywall sheets - it leaves 28 kg per 55 m of running seams, or 0.51 kg / m of running. When texturing is consumed 28 kg per 20 square meters. m, or 1.4 kg / sq. m

Sheetrock, Knauf Rothband Paste or Vetonit LR - which is better

The listed materials are the most popular among finishers. But there are features that must be considered when choosing. So, Chetrok creates the smoothest surface even without sanding. After grinding it must be primed, but without grinding this step can be skipped. Cheetrok is ideal for painting, the most durable.

Soil is necessarily applied over Vetonit, this material is best suited for the subsequent sticker on the wallpaper. The disadvantage of Vetonit in comparison with Shitrok is less ductility, but the color is perfectly white. Another drawback of Vetonit is the need for dilution, while Shitrok is a finished mass.

When comparing Shitrok and Rothband Pasta from Knauf, the following should be noted. There are few differences in the recipe; Knauf also makes high-quality material with small particles of marble and a polymer matrix. The surface after the finish coat from Knauf remains perfectly smooth, it does not need to be polished and sanded. Usually, “Rotband paste” is bought if a thicker layer is planned for sealing wall defects. Cheetrok suggests fine application - up to 2 millimeters. It is necessary to select material based on needs - then the quality of work will not cause complaints.