Putty of drywall joints is carried out even before applying the composition to the main surface of the material. Without quality putty joints it is impossible to achieve an overall good result. In this article, we will consider the issues of the correct choice of working materials and dwell in detail on the technology of sealing joints.

- Selection of materials

- Mixture "Uniflot"

- Mixture "Fugenfuller"

- Mixture "Fugenfinish"

- Mixture "Fugenfyuller-hydro"

- Surface preparation

- Puttying

- Puttying with the Uniflot mixture

- Puttying with the Fugenfueller mixture

- Useful Tips

- Possible drywall damage

Selection of materials

To putty the joints, you will need the following tools and devices:

- A pair of spatulas - narrow (100 millimeters) and wide (300-400 millimeters).

- Rubber spatula.

- Two corner spatulas with which we will process the outer and inner corners.

- Capacity for a batch of solution. The volume of dishes depends on the area of the processed surface.

- Serpianka tape with which we will reinforce the seams. An alternative to serpyanka is paper perforated tape.

- Sandpaper, which we will grind the coating, or a sanding building grater.

On the market are mixtures designed specifically for puttying joints of drywall sheets. Whenever possible, it is recommended to purchase drywall and putty from the same manufacturer, since in this case it is easier to achieve material compatibility.

to contents ↑Mixture "Uniflot"

This plaster for drywall joints allows you to do without reinforcing or perforated tape. However, the cost of Uniflot is quite high. The mixture is sold in 5 and 25 kg bags.

The method of preparation and use of the mixture:

- For 2 kilograms of powder you will need 1 liter of water. The components are mixed until a creamy consistency is obtained.

- The solution is applied to a surface previously cleared of debris and dust.

- The coating hardens after 15-20 minutes.

- The flow rate of the solution depends on how the edges of the sheets are prepared, but on average about 300 grams per square meter of millimeter coating is spent.

- Unused powder should be stored in an airtight bag in a dry room.

Mixture "Fugenfuller"

Putty composition "Fugenfyuller" is made on a gypsum basis. Components are added to the mixture to delay coating solidification. The composition is packed in containers of the same volume as Uniflot. When working with Fugenfüller, reinforcing tape or perforated paper is used.

The mixture is used not only for joining joints, but also for the following purposes:

- installation of drywall sheets on a flat surface;

- concealment of various defects on drywall;

- fixing corners on the GCR.

To prepare the solution, you need 2.5 kilograms of powder per 1.9 liters of water. The solution is thoroughly mixed. The final hardening of the coating occurs after 30-35 minutes. Putty is demanding on the lower temperature threshold: the room must have at least 10 degrees of heat. Dry powder should be stored in a dry room on a wooden pallet.

to contents ↑Note! "Fugenfyuller" should not be mixed with other putty compounds, as this will lead to a deterioration in the performance of the solution.

Mixture "Fugenfinish"

Putty for joints of drywall brand "Fugenfinish" contains a gypsum base and finely divided additives. It is mainly used for filling large areas and smoothing out minor irregularities on drywall sheets.

Advantages of the Fugen Finish:

- high ductility;

- ease of application;

- the coating is very smooth.

The solution is prepared by mixing 1 kilogram of putty with 500 grams of water. Then, with stirring, the solution is brought to a uniform consistency and left for 2-3 minutes to swell. After this, the solution is stirred again. The putty coating dries within 24 hours.

to contents ↑Mixture "Fugenfyuller-hydro"

This composition is intended for the treatment of surfaces operated in conditions of high humidity. Fugenfüller Hydro includes gypsum, as well as lime, glue, sand and water. The solution is prepared by mixing 1.5 kilograms of dry mix with 1 liter of water. After adding the components, you need to wait 2-3 minutes, and then proceed to stir the solution until it acquires a homogeneous consistency. Powder is packaged in containers of 5, 10 or 25 kilograms.

to contents ↑Surface preparation

Before filling the joints of drywall, it is necessary to prepare the surface:

- If there are protruding hats of self-tapping screws on the drywall sheet, we twist them so that they become flush with the surface.

- We make chamfers at the joints that appeared as a result of straight cuts (factory edges are not meant here). This work is more convenient to perform before installing sheets. If the work was not done on time, we take a paint knife and cut the edges at an angle of 45 degrees. Do not forget to indent 5 mm from the edge.

- We remove dust and debris from the seams.

- Apply a primer.

- After the final drying of the primer layer, you can proceed with further finishing work.

Puttying

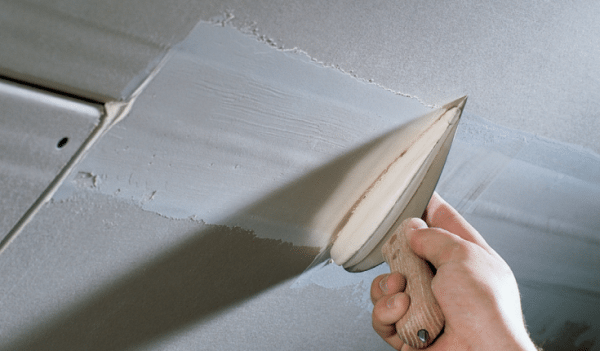

We take a wide spatula and spread the mortar imposed on it along the seam. Level the seam at the same level as the drywall surface, removing excess solution. Further actions depend on the type of putty used and the result of the work to be obtained.

Docking seams are classified by quality:

- normal;

- improved;

- High Quality.

Note! The air temperature during the processing of joints should not be less than 5 degrees heat (for some putties - not lower than 10 degrees). Moreover, the temperature level must be maintained for at least two days after completion of work.

Below we will understand how to putty the seams of drywall using the puttying compounds “Uniflot” and “Fugenfyuller”.

to contents ↑Puttying with the Uniflot mixture

The surface treatment process consists of several stages. To ensure high quality joints, at least two layers of putty will be needed. In this case, the reinforcing tape is not used.

The putty of the Uniflot drywall joints is applied to the seam with a spatula and left for 30 minutes. After the specified time, the excess filler composition is removed from the seam. If irregularities remain, we process them with abrasive material, but very carefully so as not to damage the drywall.

Next, apply a second layer of putty. We process it in the same sequence as the first. It should be noted that Uniflot is characterized by high grit, and therefore, even after the second layer, the surface is unlikely to be perfectly smooth. Therefore, for the final processing of the seam, it is recommended to use "Fugenfinish". When the finish coat is completely dry, we grind the surface to bring it to perfect condition. And the last action is the priming of the seam.

to contents ↑Puttying with the Fugenfueller mixture

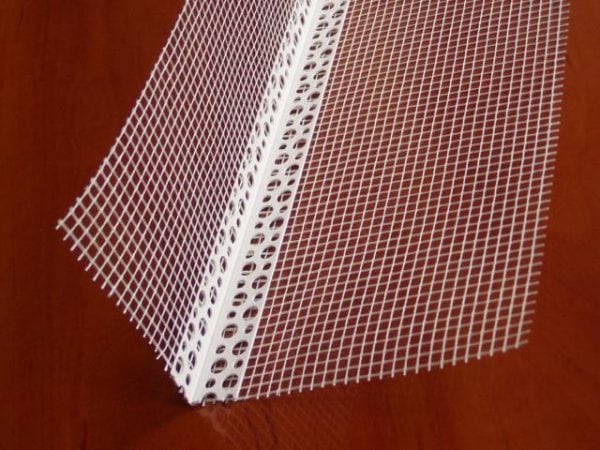

The technology for applying putty for drywall joints under the name “Fugenfüller” is somewhat different. After applying the layer, the seam is laid with reinforcing tape. The tape may be either perforated paper or a transparent plastic product with a self-adhesive surface for connection with drywall.

Useful Tips

Joints are often located not on smooth walls, but on the external and internal corners formed by plasterboard plates. We put a little mortar on the outer corner with a spatula, strengthen it with a perforated corner, and then press the corner a little. We cover the profile with putty. When sealing the joints on the inner corner, we lay the reinforcing tape at an angle of 90 degrees.

If, after installing drywall boards, a wide gap has formed between them and the floor, we close this defect with a sealant. After that, install the baseboard. In this situation, you can not rely on putty, because in this case there will be a sound bridge on the finishing material from the floor. The result of the sound bridge will be an increase in the noise level in the room and cracking of the putty layer.

to contents ↑Possible drywall damage

About how to properly putty joints of drywall, we described above. Now we will talk about how to deal with situations of damage to plasterboard sections.

One of the possible defects is bubbles at the joints of the GCR. We cut the bubbling areas with a paint knife. Small bubbles can be removed completely. Next, we tape the area around the bubble and cover the defect with putty. Level the surface with a spatula. After a day, we process the site with the finishing composition and clean this place with a fine-grained abrasive.

The protrusions at the joints of drywall sheets should also be repaired. First, we protect the protruding part of the joint, trying to align the surface of the material as best as possible. Next, take a putty knife and apply a thin putty on the joint. Let the coating dry completely (about a day). In the future, apply additional layers of putty (if necessary - depending on the size of the defect).

Cracks in tapes located at the joints are also subject to sealing. First, remove the putty from the damaged area. After that, put a little putty on the defect and press the tape there. We give the putty a day for complete drying, then to adjust the surface if necessary. If necessary, apply an additional layer of the solution.

Correct sealing of seams is only one of the stages of plasterboard puttying, however, without quality processed seams, all further work loses its meaning. Therefore, it is necessary to treat the putty of the seams with all responsibility.