The modern market for paint and varnish products offers products for every need. This applies to interior decoration, exterior work, repair and restoration of various products and mechanisms, individual decoration of objects and much more. Different varnishes and paints, primers and antiseptic impregnations, waxes and adhesive solutions have been developed for different types of base materials. Of course, there are special coating materials for varnishing various types of plastic.

- Why varnish plastic

- What varnish is plastic coated with?

- What should not be used for plastic work

- Some recommendations for varnishing

Why varnish plastic

It is assumed that varnish will protect plastic products from environmental influences. The second point is the decorative component of the coating to give the surfaces a characteristic glossy sheen. Again, using a special solution, you can enhance the color depth of the base or even completely change the color, create an unusual optical effect on the surface.

Varnishing extends the operational period of polymer products, a durable film prevents the possibility of mechanical damage to the substrate (scratches, chips, cracks). True, not everyone can use plastic varnishes. Some solutions do not react with base materials, but simply spread over the surface. Others do not dry at all. Still others in time begin to stick, warp, exfoliate. So, you need to choose a special solution for polymeric materials. Which one?

to contents ↑What varnish is plastic coated with?

Using varnish as a usual protective coating, you can choose the most common solution for plastic work, transparent glossy or matte. Note that individual materials allow tinting using pigment additives. Consider the composition of varnishes for coating plastic.

The easiest way to purchase products in a specialized store selling plastic products. There, exactly in related products there are several names of such coatings. You can go to the store for paint and varnish products for a purchase. There, with the help of a sales assistant, choose the right tool.

You should pay attention to the composition of the solution, its properties and purpose. So for plastic, mixtures with alcohol or acetone are absolutely unsuitable, since these solvents react with the polymer. So, we need water-soluble (water) varnishes.

Water-based polyurethane (or acrylic polyurethane) varnish without latex additives (latex is not suitable for plastic coating). Glossy, semi-glossy and matte solutions are distinguished by the degree of haze. An important aspect of product performance is the presence of a UV filter. If this is indicated in the composition, then you can safely use the coating (it will not turn yellow over time).

After drying, the polyurethane varnish forms a strong protective film on the surface, which protects the product from abrasion and scratches, and becomes inert to the influence of external media. The painted surface is easy to wash and clean with traditional household cleaning products without harm and deterioration of the protective properties of varnishes. Exceptional glossiness allows to achieve high-quality decorative coating even after multi-layer processing.

The undoubted advantage of all waterborne varnishes is environmental safety due to the absence of organic solvents in the composition.Therefore, such solutions practically have no toxic smell.

What degree of haze is better to choose - glossy, matte, half gloss? Here the decision is made directly to the user. It all depends on the decorative tasks of the coating. Glossy varnish usually creates a shiny film on the surface, sometimes even a mirror, reflective. Matte is less shiny, more used to convey the color depth of the plastic.

During operation, the glossy appearance is less practical, since mechanical damage on the mirror surface is more noticeable (as well as slight defects on the surface of the base).

Varnish is usually applied as an aerosol (by spraying). In this case, it turns out to put the layer more evenly without a trace of smears.

Usually a special polyurethane protective varnish for plastic products is used in the manufacturing process of the product. Therefore, in retail sales such funds are sometimes problematic to find. But consumer interest, one way or another, influenced the market supply.

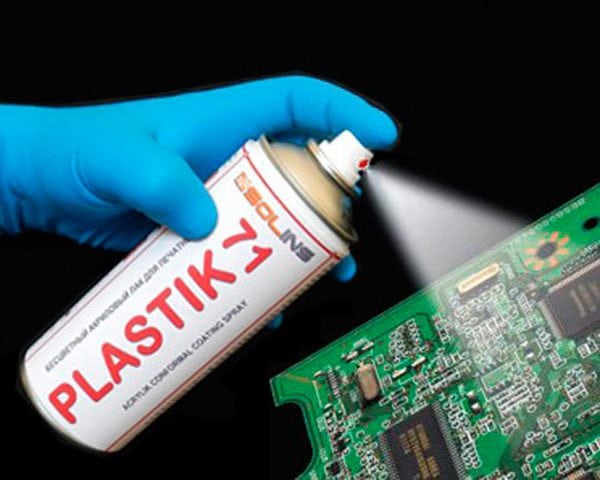

Actually, if the instructions for use of the paint and varnish product do not indicate the direct purpose of "for plastic work", but the composition is urethane (one or two component), then feel free to purchase such a tool. For example, protective spray for the electrical insulation of printed circuit boards, electric motors, transformers, electronic equipment and components. The varnish is easy to use, because it is already an aerosol (that is, it has a spray nozzle).

Such an aerosol has the following properties:

- elasticity;

- formation of a strong, transparent protective film on the surface;

- mold protection;

- water repellent ability;

- resistance to thermal and mechanical stress;

- anticorrosion properties;

- high adhesion;

- dielectric properties.

The spray is applied to a dry, clean surface. Operating conditions are relative heat and moderate humidity. After the spray is applied, you need to wait for the complete polymerization. After which it is recommended to polish the surface to get a glossy shine.

Where to find such a unique spray varnish? Protective polyurethane varnishes for electronics can be found in the same electronics stores. Or on construction markets in the department of special varnishes. Note that several well-known brands produce varnish aerosol, so the search for a remedy must definitely succeed.

to contents ↑What should not be used for plastic work

But the following types of materials called “varnish” are undesirable:

- any nail polishes (short-lived, stick over time);

- hair styling erosol (not waterproof, not antistatic);

- universal acrylic varnish mixes, including art ones (they just don’t dry on polymer surfaces).

Some recommendations for varnishing

To enhance the color depth and more spectacular appearance of a plastic product, it is recommended to apply varnish on the surface in at least two layers. This is especially true of products from metallized and translucent plastic. In general, the more layers, the better.

Each subsequent treatment should be done some time after the previous one. The intervals of interlayer drying can be found in the instructions for use of a specific varnish solution. Polyurethane water-based varnishes "on the stick" dry within 2-3 hours, fully - in a day and a half. But even after that for at least another week it is not recommended to check the coating for strength, that is, to wet it.

Small plastic products can be dipped in a solution or painted with a brush. But during drying, hanging droplets may form on the bottom of the product, which must be carefully removed while the substance is still liquid.

Another thing is to use aerosol. But here it is important to ensure that the varnish evenly covers the entire surface.Therefore, reapplication is recommended in order to eliminate any chance of omissions.

Polymeric materials themselves are quite durable. But using special protective varnish coatings, you can not only extend the period of use of the product, but also prevent negative influences from the outside. And, of course, to maintain the proper appearance of materials longer.

Good afternoon! Tell me please! Made a canoe, covered with many layers of epoxy! Dried up! Put the name of the ship! I want to varnish the whole vessel again! The question is how you can do this!

Epoxy epoxy and hardener eph 500 have a yacht varnish. Can they? Will not exfoliate?

Hello! I want to update the surface of the countertop in the kitchen with a sink and stove, since it is impossible to clean from stubborn stains. The tabletop does not know exactly what material, inside the plywood, there is a layer that looks like plastic on top. It is very dreary to glue the film, many cuts will have to be done. I thought that it would be possible to paint and varnish. Tell me, is this possible? If yes, then what will do?

Regards, Eugene

Hello. I bought a correspondent with transparent elements from acrylic. According to the reviews of the owners, this acrylic is very easily scratched even from rags. What do you advise to process? Naturally, you need to maintain transparency.

If transparency is important, you can try Crystal Clear polyurethane varnishes. They are used for application on car headlights. Transparency is top notch there.