To protect surfaces that undergo heat treatment, AK-113 varnish is used. It is also designed to prevent the destruction of products from water and high humidity. After processing metals and other materials with varnish, their service life is seriously increased.

- Product Description and Features

- Scope of application of varnish

- Varnish AK-113: consumption and specifications

- Types of varnish and their differences

- Recommended paint schemes

- Surface preparation

- Application of varnish to the surface

- Precautions and storage

Product Description and Features

Acrylic varnish AK-113 is a medium-thick liquid based on polyacrylic resin with the addition of plasticizers, diluted with organic solvents. In appearance, the varnish is transparent, slightly prone to opalescence (it shines in the light when viewed from a certain angle).

The product dries quickly: at room temperature after 2 hours it takes the form of a film that has dried to the third degree (on sticking). After drying, a smooth, transparent surface is created, homogeneous, without depressions, bumps, small crumbs and sediment. Other properties of the AK-113 are as follows:

- good moisture resistance, the ability to withstand prolonged contact with stagnant water;

- anticorrosive protection of metal surfaces;

- high resistance to solvents, radiation, minerals, UV radiation, detergents, aggressive vapors and gases, oils, gasoline, oil products;

- wear resistance, long service life;

- resistance to atmospheric factors, temperature changes.

to contents ↑The adhesion force of the varnish to the product is very high, due to which the coating literally “fuses” with the surface. The film is elastic, but strong, does not soften from the action of chemicals. AK-113 is sold in flasks of 15 kg, drums of 25 kg, barrels of 35-57 kg.

Scope of application of varnish

The main area of use of the product is surface treatment of metal. The varnish is intended for application to objects of ferrous, non-ferrous metals, alloys that work under normal conditions or with heating up to +150 degrees. Most often, the tool is used for such materials:

- aluminum;

- magnesium and its alloys;

- brass;

- copper;

- stainless steel;

- zinc and galvanized surfaces;

- titanium.

The varnish is also suitable for various non-metallic substrates made of plastic and plexiglass, wood, cardboard, paper. After drying, the products can be operated in any climatic zones.

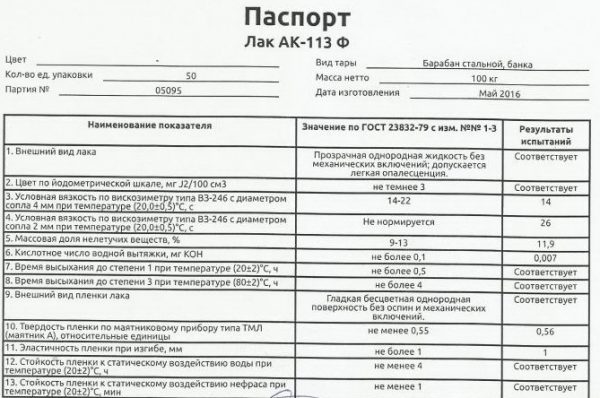

to contents ↑Varnish AK-113: consumption and specifications

The theoretical consumption of funds per layer is 115-140 grams per square meter. One liter of varnish is enough for 7.1-8.6 square meters of surface. Recommended layer thickness should be 10-12 microns. 1-3 layers are usually enough to create reliable protection, depending on the type of material.

Other technical characteristics of the varnish are as follows:

- conditional viscosity according to VZ-4 (VZ-246) with a nozzle diameter of 4 mm - 13-17 s;

- the acid number of the aqueous extract is 0.1 mg KOH / g;

- fraction of solids - 6-9%;

- bending film elasticity - 1 mm;

- the hardness of the film according to the TML instrument (pendulum A) is 0.45 relative units;

- film resistance to water at a temperature of + 20 degrees - 4 hours, to nephras - 1 hour.

Types of varnish and their differences

There are two types of varnishes on sale: AK-113, AK-113F. The fields of application of both are the same, as well as the appearance of the created film. There is a difference in the composition: the first tool is created only on the basis of polyacrylic resin, the second melamine formaldehyde resin is additionally added. Due to the changed composition, the AK-113F differs from the AK-113 in some technical characteristics:

- drying time increased to 4 hours;

- the proportion of solids is 9-13%;

- consumption per layer is less - up to 90-110 g per square meter.

to contents ↑In general, the other properties of varnishes are approximately similar: both are waterproof, wear-resistant, give products strength, protect against UV rays, chemicals and corrosion.

Recommended paint schemes

If the product will be operated in a normal climate, excluding sudden changes, it is possible to apply varnish in 1-2 layers, as indicated in GOST in the "Technical Parameters" section. When operating in extreme climates, the number of layers should be increased: for the tropics, 3-4 layers are needed, for cold weather conditions - 2-3 layers.

Surface preparation

The level of degreasing of the base should be 1 (according to GOST 9.402), and the degree of purification from oxides - 2. Thus, any surfaces must be thoroughly cleaned, remove all dirt, dust, grease, clogging. This can be done by wiping with a rag dipped in white spirit. For non-metallic substrates, it is best to use alcohol or other safe solvents. Before applying varnish, the material should be well dried.

to contents ↑

Application of varnish to the surface

The varnish can be diluted with solvents 646, R-5A, they also subsequently wash the tools. Before use, the product must be kept at room temperature for at least 2 hours. It is easy to apply, for this purpose they take an ordinary brush, and for large surfaces - a pneumatic sprayer.

to contents ↑During work, the temperature can vary from +10 to +30 degrees, humidity - up to 90%. At low temperatures, applying varnish is not recommended. To prevent condensation, the temperature of the product should be above the dew point by 3 degrees or more. The first layer is applied in the usual way. The second layer is permissible to perform only after 2 hours, that is, after sufficient drying of the first.

Precautions and storage

Varnish is flammable! You can not use it in conditions where there is a risk of contact with sources of open flame. During work with varnish and drying of the base, good ventilation should be established in the room. Before staining, you need to take care of personal protective equipment: gloves, glasses, a respirator.

If the product enters the stomach, you need to rinse and call a doctor! Wash skin that has been varnished and wash with warm water and soap. Store the AK-113 in a closed container, excluding contact with water, contact with the sun. You can leave the varnish at a temperature of + 30 ... + 30 degrees. Shelf life is 10 months. After completion of work, the remaining solution, if necessary, must be disposed of in compliance with environmental standards.