Although metal is a fairly strong, durable material, it nevertheless deteriorates over time. Faster designs become unusable under the influence of certain physical and mechanical influences. For example, everyone knows that dampness, high and low temperatures, and aggressive chemical environments adversely affect metal surfaces. Therefore, it is recommended to take measures to protect the surfaces of metal structures, for example, to use metal varnish.

- Types of varnishes for metal

- Bitumen varnish

- Polyurethane varnish

- Acrylic lacquer

- Alkyd varnish

- Oven varnish

It can be a colorless varnish or with a pigment (like bitumen, which after drying forms a dark protective film). Let us consider in more detail what paints and varnishes can be used to protect iron?

to contents ↑Types of varnishes for metal

Consider the most popular types of varnishes for metal processing.

Bitumen varnish

Since we have already mentioned bitumen, we will start with it. This is a relatively new type of varnish mixes. It is produced on the basis of a special grade of bitumen and polymer resins mixed with organic solvents and additives. It has excellent physical, mechanical and operational properties. Designed to protect the surface of metals, stone, wood.

Although the black protective film formed is strong and resistant to external influences, manufacturers suggest using varnish as a temporary rather than a permanent solution, that is, during storage and transportation of products.

Bitumen varnish has the following characteristics:

- environmentally friendly;

- porous structure provides frost resistance;

- lasting;

- elastic;

- heat resistant;

- weatherproof;

- resistant to acids and alkalis;

- possesses antiseptic properties.

Bitumen varnish is inexpensive, but quite high quality. Today, materials in this category are becoming increasingly popular.

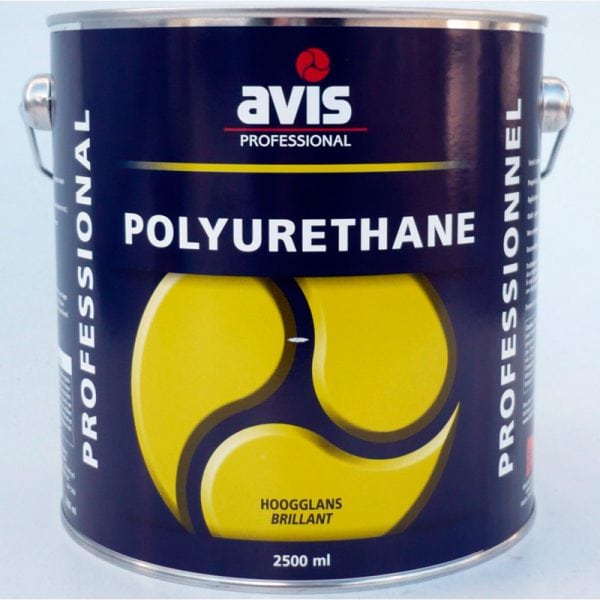

Polyurethane varnish

Available: transparent, glossy, matte. The composition of the substance includes modern polymers (polyurethane). It has excellent performance. Corrosion-resistant polyurethane solution is used as a protective finish coating on the inner surfaces of tanks made of steel, cast iron, aluminum, copper and their alloys.

Polyurethane varnish is also suitable for domestic use when performing internal or external finishing work. Easy application, quick drying, does not form smudges. Temperature atmospheric threshold during work: from -30 ° C to + 60 ° C.

Characteristics of polyurethane varnish:

- excellent adhesion;

- wear resistant;

- heat-resistant (temperature range during operation from -60 ° С to + 80 ° С);

- strong, stable, elastic coating;

- moisture resistant;

- chemical inertness;

- atmospheric resistance;

- long trouble-free operation of the coating and the product itself (at least 10 years).

Transparent polyurethane varnish allows mixing with pigment (to obtain a colored decorative protective layer). It can be used as a main (finish) coating or to protect metal before painting.

to contents ↑Acrylic lacquer

It is used to protect products from ferrous and non-ferrous metals and their alloys. The coating dries very quickly, a durable waterproof film forms on the surface. Among the recommendations for use, we highlight: suitable for metal surfaces that are constantly in conditions of high humidity and high temperatures.

The basis of the varnish is an aqueous dispersion of acrylic resins. Application is recommended to be done with a spray (like an aerosol) or a paint brush. It can be applied for external, internal works. Many automotive paints and varnishes are also available on the basis of acrylic resins.

Characteristics of acrylic varnish:

- heat resistant;

- moisture resistant;

- possesses good adhesion;

- anticorrosive properties;

- not affected by salts, oils;

- forms a strong, flexible film that can withstand mechanical stress;

- non toxic

- fire and explosion safe;

- extends the service life of structures made of steel and other metal alloys.

to contents ↑

Alkyd varnish

It is made on the basis of alkyd resins and polymers. Gives lacquered shine to metal surfaces. It is applied as an aerosol, as well as by brush or roller.

Characteristics of alkyd varnish:

- creates a strong protective coating;

- resistant to acids, alkalis, alcohols, household chemicals;

- moisture resistant;

- heat resistant;

- wear resistant;

- has a high level of adhesion;

- resistant to mechanical stress;

- Applicable for indoor and outdoor use.

Oven varnish

This is a special kind of paint protection. The material is heat-resistant (can withstand temperatures of + 250 ° C, creates a hydrophobicity of the product, protects against corrosion, all weather resistance is very high. It is used as a modified additive in alkyd, acrylic and other paint and varnish mixtures. They can cover brickwork and metal parts of the furnace. When performing outdoor and interior work is not affected by atmospheric conditions.

For painting metal surfaces it is very important to choose a tool that protects the product as much as possible from the harmful effects. Transparent lacquers for metal are so valuable in that they can act both as an independent decorative tool and as a protective base before painting. Important properties of such solutions: anticorrosion, weather resistance, heat resistance.

Hello. I need a varnish or paint of red color, for inscriptions on metal utensils, what can I recommend?