Paints and varnishes are usually applied in several layers. Moreover, each subsequent layer can be applied only after the previous one dries. If, for some reason, the varnish dries for too long, household inconveniences arise, since it is impossible to use a dry surface, and the repair time is seriously delayed. Is there a quick-drying varnish, why some compounds dry quickly and others slowly - this will be discussed in this article.

- Classification of varnishes by stages of drying

- The dependence of the drying rate on the type of varnish

- Ways to Speed Up the Drying Process

- Reasons for prolonged surface drying

Classification of varnishes by stages of drying

The drying of paints is differentiated into three categories:

- Drying time on the stick, that is, the period that is necessary so that dust and debris do not stick to the varnish. Drying time on a stick, can vary from 10 minutes to several hours.

- The drying time of the layer. This parameter indicates the time interval between the application of varnish and its drying to the extent that you can apply the next layer. The indicator can be from an hour to a day.

- Time for the final drying of the varnished surface. Operation of the surface can be carried out only after complete drying of the paintwork. The waiting time can vary from 3 to 36 hours.

Note! If the varnish is already well thickened, but not yet completely dry and you need to urgently pass along the varnished surface, you can put cellophane or ordinary bags on the floor. The use of a carpet path is also acceptable, but in this case there is a possibility that lint will remain on the varnished coating, which can then be difficult or even impossible to remove.

to contents ↑The dependence of the drying rate on the type of varnish

Drying speed is one of the main qualities of the paintwork material. In practice, things are usually such that an improvement in one parameter of the composition leads to a deterioration in other characteristics of the varnish.

For example, quick-drying compounds are more expensive than usual and at the same time they are not always environmentally friendly, and in some cases very short-lived. In addition, the drying time of the surface is a relative concept: one master wants to get a dry surface after an hour, the other is ready to wait a couple of days, if only the coating was of high quality.

The question of how much the varnish dries depends on many factors, but the composition of the paintwork material can be considered the main one. Nitrocellulose varnishes are among the fastest drying ones, but water-based acrylic compositions dry for a long time. Below we consider the main types of varnishes, in terms of their drying speed:

- Nitro-lacquers (transparent and matting) are produced on a colloxylin base, they contain resins, solvents and plasticizers. Varnishes of this group are characterized by moisture resistance and the highest drying rate. Drying time on a stick, can vary from half an hour to an hour. Final drying occurs within 3-5 hours. At the same time, nitro-varnishes do not belong to environmentally friendly compounds, since they contain highly toxic solvents. Therefore, nitro-varnishes can not be used for finishing work in rooms intended for human habitation. It is also worth noting another drawback of nitro-lacquers - insufficient coating resistance.

- Polyurethane materials are used to process wooden parquet, laminate, furniture, polymer bulk floors. The compositions of this group provide excellent resistance to moisture and aggressive chemicals, as well as resistance to mechanical stress. The primary drying of the surface occurs within an hour, and the final - in the interval between 4 and 12 hours. Bicomponent formulations dry best because they have a hardener. Experts consider polyurethane compositions to be a good option, providing a good ratio of drying time and surface quality.

- Water-based varnishes are free from unpleasant odors, and are also among the safest. However, such compositions dry for quite a long time - sometimes up to 10-14 days. Last but not least, this is due to the need to apply several layers of water-soluble varnish, otherwise the surface will not gain the necessary strength. Also, the low drying rate is due to the fact that water evaporates much more slowly than organic solvents. It should be borne in mind that coatings treated with water-based paints and varnishes are not very resistant to moisture and temperature extremes. The drying time of water-soluble varnishes on the stick is 2-3 hours, the final drying occurs after 18-36 hours.

- Oil paints are made from wood resins and linseed oil. Oil formulations are diluted with organic solvents. With all its advantages (protective qualities, appearance of the obtained surface, environmental friendliness), oil formulations are considered one of the worst options, in terms of drying speed. The complete drying time is usually from 48 hours or more.

- Alkyd varnishes, as well as oil varnishes, are combined with organic solvents. As a result, compositions based on alkyd resins gain moisture resistance as well as strength. It is recommended to apply alkyd paintwork material from a spray can. Alkyd varnish dries in about 72 hours. However, if there is a need to speed up the process, a hardener can be added to the composition, which will reduce the drying time to a day. Alkyd-urethane varnishes also have quicker drying compositions based on alkyds. Due to the presence of urethane alkyds in their composition, such varnishes dry in about 12 hours.

- Epoxy varnishes can be used for both indoor and outdoor use. At room temperature, a surface coated with an epoxy resin composition will dry for approximately 24 hours.

- Yacht varnishes have a variety of drying times. For example, Aurlak dries in 8 hours, Alkidlak in 16, Aurlak-express in 12 hours. But “Poliurlak” refers to quick-drying and sets in 45 minutes.

Ways to Speed Up the Drying Process

There are several ways to obtain a finished surface in a relatively short time:

- Warming the treated surface with an industrial hair dryer.

- The use of so-called fast solvents, which evaporate more actively in comparison with conventional types of solvents.

- The use of quick-drying grades of paints and varnishes. Such varnishes are based on organic solvents and include special hardener additives.

Reasons for prolonged surface drying

In case of violation of the technological regime, the varnish can dry for a very long time, and in some cases the surface will not dry at all. The following are the main factors that can cause the coating to dry too long:

- Low-quality paintwork. This is most often the main reason. Do not save on varnish.

- Too thick varnish on a wooden surface.The second and all subsequent layers of paint material are absorbed much worse than the first layer.

- Foreign oil residue on the coating.

- Mismatch of varnish to the primer or wood grade.

- Failure to comply with the proportions when preparing a two-component varnish.

- High humidity in the room.

- Violation of the recommended temperature.

Advice! It is recommended to apply varnish with a brush. However, the use of a roller or spray is also allowed. If the choice fell on the canister, and at the same time you have to work in conditions of elevated temperature, you need to finish the water in the composition in a ratio of no more than 1 to 10.

Information on how much parquet varnish dries is indicated on the packaging by the manufacturer. It should be borne in mind that this indicator is established on the basis of experiments in predetermined climatic conditions (more precisely, in a certain microclimate). If, in reality, the humidity and temperature indicators differ from the recommended ones, the solidification time can change significantly, both for the better and for the worse.

Separately, it should be emphasized the importance of observing the recommended parameters of temperature and humidity. The optimum temperature for drying the paint material is from 18 to 22 degrees above zero Celsius. If the temperature is too low, the varnish will harden longer than the stated time, and if the temperature is too high, the coating will dry out and cracks will appear in it.

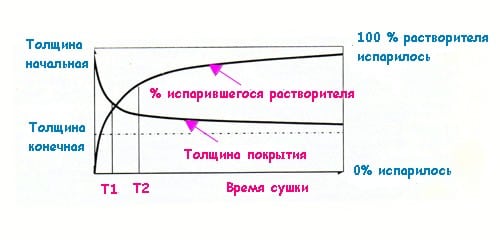

Moisture level is another important parameter that affects the drying rate. This is especially true for water-soluble compositions, since their solidification is based on the evaporation of moisture, resulting in an increase in the concentration of film-forming substances. Of course, in conditions of high humidity (more than 50%), there can be no question of quick hardening of the surface.

Even if the most quick-drying varnish is used for parquet or other wooden products, the surface will have to be protected from mechanical damage in the early days. Also, do not allow dust or dirt to get on the lacquered wood. If contaminants occur, it is recommended to wash them off with ordinary household chemicals.