Laminate is a modern material that is widely used for flooring. This material consists of several layers, the outer of which is a protective film. Its outer layer is highly resistant to wear. However, despite this, during daily intensive use, it can wear out. Therefore, for restoration, the laminate can be painted with ordinary or uv varnish.

Especially the material wears out in places of increased friction, for example, under the wheels of chairs, legs of chairs, tables and so on. Even the most popular laminate, which is of high quality and wear resistance, can still lose its presentable appearance over time. The only way out in this situation is to coat the laminate with varnish. This is the only way to restore its original appearance to the coating.

Can laminate be varnished?

Many people think that laminate should not be varnished. They give the following arguments:

- The outer side of the coating plate has a protective film having an absolutely smooth surface. This surface has zero adhesion, so paints adhere to it extremely poorly. There are no pores in the film, so it cannot absorb liquid components. Accordingly, when applied to a laminate, any varnish coating may peel off or lag behind.

- Laminate flooring is a floating floor, as its elements are not fixed to the substrate and can be slightly displaced in relation to each other. Accordingly, if you paint a similar floor with paints and varnishes, then it can begin to crack at the joints of the plates.

However, in modern conditions, all these problems are easy to solve. Therefore, laminate varnish is becoming increasingly popular. Consider how to solve problems with coverage:

- To solve the first problem associated with the protective film, it is necessary to choose the right type of paint material. To select, you need to find out what material the protective film on the flooring is made of. As a rule, the protective layer of the plates can be acrylic or melamine (plates from the manufacturer Nevsky Laminate are coated with a melamine film). Accordingly, the acrylic film must be painted with acrylic, and melamine - with a paint and varnish material based on melamine or polyurethane. Accordingly, two identical coatings will adhere well to each other.

- To solve the second problem, use the correct styling method. It implies competent preparation of the base with its maximum leveling. If you lay the laminate on a properly prepared base, the plates will never move and no cracks will appear at their joints.

to contents ↑That is, if you choose the right paint and varnish material and prepare the surface well, then coating the laminate with varnish will help maintain the appearance of the surface and will not create any inconvenience.

Rules for applying varnish on the laminate surface

If you are going to paint a newly laid laminate or other floor covering, then all particles of debris and dust should be removed from it.The same should be done with the laminate, which, due to long-term operation, managed to lose its appearance. Before applying varnish, the surface must be absolutely dry and clean. If there are scratches, chips or various defects on the surface, they should be treated with a special paste or putty.

It is desirable that the color of the paste matches the color of the laminate surface. If there are deep cracks on the coating that reach the lower layer of wood, it is recommended to fill them with ordinary PVA glue. It is worth noting that categorically it is not recommended to engage in scouring or grinding of the laminate flooring, whatever it is. This can lead to the destruction of its structure and the loss of a presentable appearance.

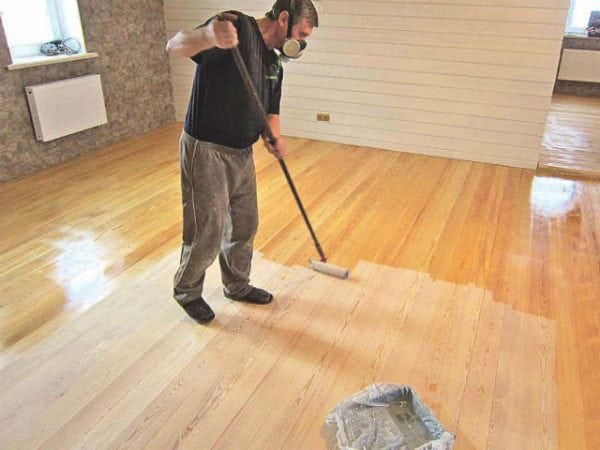

After the putty or glue is completely dry, a layer of varnish can be applied to the surface. Varnish is applied with a paint brush or roller. In this case, it is better not to rush and do everything as carefully as possible. It is better to apply a paint and varnish material in a thin layer in several stages. Before applying the next coat, allow the surface to dry well. It is recommended to cover any laminate with not less than three layers of varnish. When working with a surface of light color, you can use transparent or white varnish. For a dark laminate, only a transparent paintwork is suitable. After proper application of varnish on the surface, it will get a presentable appearance and will become more wear-resistant.

to contents ↑UV laminate coating

One of the modern paints for flooring is uv laminate flooring. It is made by passing through a special camera with uv rays. As a result, the varnish obtains unique physical properties due to the presence of alumina in the composition, due to which rapid solidification is observed.

The advantage of such a paint and varnish material is that due to the quick hardening, the surface remains perfectly clean and small particles of dust do not settle on it. Of the disadvantages, it is worth noting the greater fragility of the outer oxide layer compared to conventional paint material. With proper surface preparation, uv varnish can be applied to any laminate. By the way, the front side of the "Nevsky" laminate is also covered with several layers of UV-varnish and dried under the influence of uv rays.

Thus, varnish is increasingly being used to cover the laminate. It should be applied only to a properly prepared surface, which will allow to maintain the aesthetic characteristics of the flooring at the proper level.