How to extend the life of plywood, provide it with a long service life and proper appearance for the entire period of operation? You think this is impossible - and you are mistaken, because modern paints and varnishes can significantly extend the time that it can last. Use suitable varnishes and paints of the proper quality for these purposes, and you will get an excellent result.

- Why is varnishing needed?

- For what types of plywood varnish is recommended

- What varnishes are used for varnishing

- How to apply?

- Final chord

Why is varnishing needed?

90% plywood consists of wood, which can easily become unusable in conditions of high humidity, exposure to aggressive environments, fire and mechanical damage. Wanting to keep the natural building material intact for as long as possible, specialists in the repair profession apply varnish, which provides plywood with durability and a beautiful shine.

For what types of plywood varnish is recommended

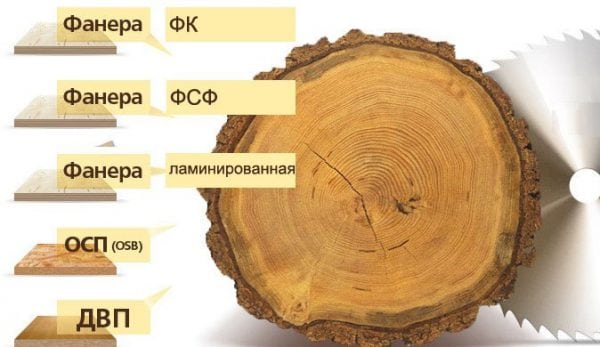

Today, there are about 20 types of plywood, each of which, depending on its weight and properties, is involved in a certain field - modeling, design, aircraft and automotive industry, monolithic construction, repair and roofing, design and manufacture of containers. Many of its varieties are involved exclusively in production and are not used in everyday life. The most popular brands that both pros and amateurs work with pleasure with pleasure are two brands: FSF and FC.

FSF is a plywood of increased moisture resistance and is mainly used in exterior decoration. Due to its strength and durability, it is used for the manufacture of laminated plywood.

FC plywood is more environmentally friendly and natural, with less protective impregnation and therefore more vulnerable to exploitation. She is most often involved in repairs, and more specifically in:

- wall cladding (alignment, insulation);

- sound insulation and ceiling insulation;

- creating a base floor ("rough floor") for a board, linoleum, parquet and laminate;

- creating false walls and partitions;

- renovation of the roof.

It is FC plywood, which has medium moisture resistance, varnishing is simply necessary.

to contents ↑What varnishes are used for varnishing

When buying varnish, sellers will pay your attention to the opportunity to choose a paint product by the type of film coating. There are two of them:

- Polymerization. The application of a complex chemical composition of the dye and its subsequent drying gives a strong coating layer as a result of hardening. These varnishes include polyurethane, polyester, alkyd, oil and formaldehyde.

- Evaporation (volatilization) of solvents - this is present in nitrocellulose and alcohol-containing varnishes.

The most popular in everyday life are alkyd compounds based on pentaphthalic or glyphthalic resin (GF-166, PF-283, GF-177, PF-231). They give a transparent color (sometimes with a slightly brownish tint), have good adhesion to the material and are waterproof, suitable for indoor and outdoor use.The first layer of alkyd varnish dries from 36 to 72 hours, repeated application is done with a brush.

Oil varnishes, like alkyd ones, contain natural or less expensive synthetic resins and oil-based solvents. The coating that they give has a transparent yellowish color and sufficient hardness. Oil varnishes are used for varnishing floors, furniture, decor items and souvenirs. In comparison with alkyd, oil varnishes lose only in one thing - instability to the influence of atmospheric phenomena and long drying. However, today oil compositions have already appeared with a clear miscalculation of the proportion of resins, which are able to dry in 12 hours and show resistance to atmospheric phenomena.

Nitro lacquers perfect for the protective treatment of wood products and plywood in particular. Their drying properties are close to ideal - 15-30 minutes, and the film is striking in its absolute transparency and lack of color (NTs-218, NTs-221, NTs-222, NTs 228).

Epoxy varnishes are a compound of the eponymous resin and an organic solvent. Before starting work, they add a hardener in the appropriate proportion. After drying (about a day), a very strong and transparent epoxy film is obtained, the only minus of which is instability to the effects of the atmosphere. That is, these paints and varnishes are optimum for internal works.

Polyurethane paints also perfectly cover the wood surface. These compounds form a strong transparent film that perfectly protects the plywood sheet from scratches and bumps, aggressive chemicals and moisture. Drying takes from 4 to 12 hours. Today it is one of the best options for coverage.

to contents ↑How to apply?

Depending on the composition, paints and varnishes are applied using:

- spray gun;

- roller;

- wide flat brush.

Final chord

After applying the varnish on the surface of the plywood and completely drying it out, it is worth adding another obligatory touch: cover the surface of the building material with a layer of special drying oil or oil. This will provide a saturation effect of the wood color of plywood and enhance the luster of fresh varnish.