Thermal insulation paint is an innovative paint material based on a polymer composite containing hollow ceramic spheres. Thermal insulation compounds are gaining more and more popularity due to their technological features. They not only act as a coloring matter, but also allow you to additionally insulate the material to be painted.

- Areas of use

- Functional Features

- Advantages and disadvantages

- Types of paints

- Thermal paints

- Foam Insulators

- Criterias of choice

- Manufacturers

- Paint amount calculation

- Surface preparation

- Paint application

- Conclusion

Areas of use

Thermal insulating paints are used in such areas:

- insulation of industrial equipment;

- coloring of technological capacities;

- agricultural production;

- basement insulation;

- protection of heat transfer systems;

- processing automobile and other modes of transport;

- thermal insulation of housing (both internal premises and building facades);

- protection of utilities, pipelines, ventilation and air conditioning systems.

Protective paints and varnishes are used in almost all industries where it is necessary to protect the material from freezing. Thus, heat-insulating paints are a direct competitor to building insulation materials.

to contents ↑Functional Features

The thermally insulating paint material contains the following components:

- water;

- acrylates;

- fillers;

- additives.

At its core, thermal insulation coatings are divided into two types:

- Water based. Used for coloring heating systems. Differ in the absence of toxicity and a smell.

- Based on acrylates. They are a universal option. Such paints are used for processing all types of surfaces.

Ceramic granules, foamglass, fiberglass, perlite act as additives. The consistency of protective paints resembles a gray or white paste. The composition is applied on the surface with a very thin layer (from 2 to 4 mm). It is enough to replace dozens, or even hundreds of millimeters of insulation materials.

An important advantage of painting is the ability to get to almost any area. With a traditional insulation, it is not always possible to do the same.

Paint is applied using brushes, rollers or spray guns. Moreover, the latter is preferable, since they allow you to create a uniform surface.

The thermal insulation properties of the coating are also determined by its thickness. The more layers, the higher the protective qualities of the surface.

The service life depends on the type of painted material and operating conditions. The coating does not lose its properties for 10-50 years at ambient temperatures from -40 to +250 degrees.

to contents ↑Advantages and disadvantages

The advantages of thermal insulation compounds include:

- heat saving;

- high resistance to mechanical stress;

- excellent adhesive characteristics (adhesion of dissimilar materials);

- long service life of coatings;

- low heat transfer coefficient;

- resistance to ultrasonic waves;

- resistance to atmospheric precipitation;

- heat resistance;

- high strength coatings;

- simplicity of thermal insulation;

- almost complete preservation of the dimensions of the object after staining (due to a thin layer of paint);

- fire safety;

- environmental friendliness;

- resistance to the development of corrosion processes;

- a small coating mass (especially important for facades and pipelines).

However, liquid insulation can not be attributed to universal materials, since it also has negative characteristics:

- High price.

- Not all ultra-thin coatings provide high-quality thermal insulation.

- The best results can be achieved only with a significant difference in temperatures between the environment and the coating. In other words, heat-insulating paints and varnishes are an ideal choice when it comes to hot pipes. But thermal insulation for walls outside or inside a building is sometimes more appropriate to perform with traditional materials. The use of heat-insulating paints is justified in those places where the use of standard insulation is impossible or difficult.

Types of paints

Two types of paints and varnishes belong to heat-insulating materials:

- Thermal paints (these include ceramic compounds).

- Foam fillers (including those based on penoizol, polyurethane foam, liquid foam).

Thermal paints

Technologically, the application of thermal paint is no different from painting the surface with any other paint composition:

- First, apply the first layer, after which they wait for the surface to dry. Then several more layers of paint material are applied. Usually we are talking about 5-6 layers of paint, but sometimes their total number reaches 10.

- The paint is applied using any convenient device, but it is better to opt for a spray. It is very important to achieve a uniform coating, since otherwise the use of a heat insulating composition loses all meaning.

- When the paint dries, a dense thermal film appears on the surface, providing low thermal conductivity. In addition, the film gives other qualities to the coating, including mechanical strength, resistance to ultrasound, humidity, etc.

Foam Insulators

Foam paints and varnishes are completely different from thermal paints by surface treatment and technical parameters. Among the features of working with foam insulators are the following:

- In the absence of experience, foam insulators can be easily confused with polyurethane foam. This is especially true of penoizol (Astratec can be given as an example of such a heater).

- The basis of the insulator is a polymer substance that reacts with oxygen, resulting in a dense coating after drying. The polymer is mixed with the foam generating material.

- It is due to the presence of a foam generator that a large amount of foam appears, filling all micropores. The foam generator is characterized by excellent adhesive characteristics and therefore reliably fastens to any building material.

- A feature of penoizol is the absence of sagging on vertical surfaces. After only half an hour or an hour, the coating begins to dry out, and after 4 hours the drying process is completed. The curing rate directly depends on the characteristics of the temperature and humidity of the environment.

Penoizol is the most affordable material. However, for the purpose of thermal insulation, other compositions containing polyurethane foam and liquid foam are also used. At the same time, penoizol is the least durable in comparison with competitors.

Polyurethane foam is considered to be better than penoizol. In particular, it is stronger and better able to cope with mechanical stress.

Liquid foam is polystyrene with the addition of a foam generator. Liquid substance differs from ordinary polystyrene in its internal structure and consistency. However, after drying the coating, any differences are nullified. In this case, the hardened liquid foam is more likely more similar to foam, since air bubbles are visible on a dried surface.

to contents ↑Criterias of choice

When buying heat-insulating paint, it is recommended to pay attention to the following factors:

- Heat resistance.This indicator is especially important if you have to paint the pipeline.

- When choosing a paint for exterior or interior use, the surface conditions are taken into account. For example, to insulate the facade, you should choose a paint with maximum resistance to moisture and high permeability. For indoor coverage, environmental safety is considered the most important characteristic.

- Consumption per 1 m2.

Manufacturers

On sale there is a significant variety of heat-insulating paints and varnishes. Among the most popular, the following brands of paint can be distinguished:

- Liquid thermal insulation Corundum. Under the popular brand "Corundum" several types of heat-insulating compounds are produced, varying in functionality. In particular, “Corundum Classic” is intended for insulation of pipes heating up to 200 degrees. "Corundum Facade" is used for external thermal insulation. "Corundum Anticor" is used to protect metal in conditions of high humidity (for example, when covering the roof). Corundum paint is offered in cans of 3 or 10 kg, as well as in 20-liter buckets. The coating retains functionality at temperatures from 60 degrees. frost up to 250 degrees. heat.

- Astratech. Represents a paint without the content of organic solvents. In this regard, Astratech is completely environmentally friendly. Use such paint for the treatment of especially hot surfaces (pipelines, boilers, industrial equipment). There are modifications with anti-corrosion additives.

- The Bronya heat-insulating paint contains ceramic components. The anti-condensation additive together with the anti-corrosion properties allows the use of painted coatings in extreme conditions. Another feature of the “Armor” is the ability to withstand ultraviolet radiation, regardless of the duration of exposure to radiation.

- "Akterm - Standard." The paint creates coatings that withstand very high temperatures - up to 600 degrees. The minimum temperature at which the coating retains functionality is 60 degrees. below zero. The paint is versatile, it is used both for residential premises and industrial facilities (pipes, refrigerators, etc.). Universality is achieved due to the absence of toxicity and fire safety of the composition. Paint can be applied even in winter, provided that the air temperature is not lower than 25 degrees. frost.

There are many other paints with thermal insulation properties. Among them are such compounds as Alfatek, Teplomett, Keramoizol, Magniterm, Tezolat, Teplokor, Kare, Thermosilat, Maxidom, Hydrostop pro and others.

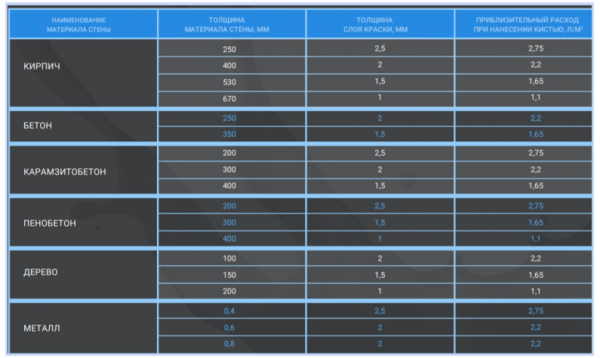

to contents ↑Paint amount calculation

The amount of paint consumed depends on many variables, including:

- a variety of base coat (concrete, expanded clay concrete, foam concrete, wood, metal, brick);

- flat or uneven surface;

- the presence or absence of pores;

- surface area;

- paint coat thickness;

- in the case of pipes, the diameter of the pipeline;

- weather;

- paint application method (brush, roller or spray).

The excess of paint consumption over the average is largely determined by the type of surface. In particular, for concrete and wood, the excess is 5-10, for metal - 3-6%. The greatest overspending is observed when staining relief, porous or rough surfaces - from 15 to 35%.

Note! In conditions of good calm weather, paint consumption is reduced by 2-3%.

The average paint consumption is 1 liter per square meter, provided the millimeter layer. However, for some types of materials, thicker layers are recommended. For example, for concrete - 1.5, brick or foam concrete - 2.5, wood - 2 mm.

to contents ↑Surface preparation

Before applying the paint, it is necessary to qualitatively prepare the surface. On a dirty uneven basis, the coating will not last long, and therefore all efforts and financial costs will be in vain.

Dust, dirt and oily formations are carefully removed from the surface. All cracks and cracks close up. They also get rid of irregularities, for which they use a metal brush, grinder or sandblasting machine.

Note! In the case of concrete, the surface should be cleaned of the so-called "cement milk" - dust, which greatly impairs the adhesive quality of the coating.

When the surface is cleaned and mechanically leveled, a primer is applied. As primers, VL-02 or VL-023 is most often used.

to contents ↑Paint application

Surface painting is carried out as follows:

- Stir the paint first. The process is carried out right up to uniform distribution of microgranules in the composition. Stirring time is 10-15 minutes. The process can be accelerated to 5-7 minutes, if there is a mixer. In this case, the speed of rotation should not be higher than 200 rpm. Too high a speed will destroy ceramic microbeads.

- If necessary in accordance with the instructions for use, water is added to the composition.

- To stain areas that are insignificant in area, use brushes with natural pile. For painting on larger surfaces, without numerous corners and irregularities, it is more convenient to use a roller. The most high-quality application of paint is achieved when using a spray gun (airbrush or airless spray). When applying paint, you need to monitor the working pressure: it should not exceed 6 atmospheres, since otherwise damage to ceramic microspheres is likely.

- After painting the surface, you need to wait a day until it dries. During this time, the binder is polymerized and the heat-insulating microgranules are fixed. Drying speed may vary depending on environmental conditions. The manufacturer indicates the containers with paint the recommended temperature and humidity for the normal drying process of the coating.

When working with paints and varnishes, personal protective equipment should be used. You will need a respirator, rubber gloves and safety glasses. If paint gets on the mucous membranes, it is necessary to rinse the affected area with water and immediately seek medical help.

to contents ↑

Conclusion

Thermal insulating paint is a great way to insulate materials. However, a liquid heat insulator is not a panacea in all cases, sometimes it is more correct to use traditional heaters. It is also important to follow the instructions of the manufacturer, since in case of a violation of the technological process, coloring will not lead to the desired result.