Recently, rubber paint appeared on the market, the material immediately took a strong position among users. It is used inside and outside buildings - it is best suited for external work.

- Description of rubber paint

- Types of paint

- Composition

- Volume and form of release

- Colors

- Storage and transportation conditions

- Features, advantages, disadvantages

- Fields of application

- Rubber Coated Materials

- Preparation and application

- Cleansing

- Primer

- Dyeing

- Paint consumption and surface care

- Manufacturers

Conventional compositions when painting the roof and walls in a couple of years require updating: their color fades, cracks, defects appear, rust forms on the metal. Painting houses, structures and various products with rubber paint gives an excellent result, very different from the effect of conventional coatings.

Description of rubber paint

Rubber paint is a paint and varnish material made on the basis of acrylic water dispersion with the introduction of latex, modifiers and other components. The peculiarity of the paint is the creation of a unique elastic layer that protects the surface and gives it a very beautiful appearance.

The material contains no organic solvents, the paint is recognized as safe for humans and the environment, has no smell, does not emit toxins.

to contents ↑Types of paint

The tool got its name because of the ability after drying to take on the appearance of a soft film similar to rubber. The paint resembles the polymer mastic used for the production of bulk floors. Conventional coatings do not differ in this effect - as the compositions dry, the compositions become solid even externally.

There are many types of rubber paints that vary in composition, color, purpose, form of release.

In the area of use of the tool are:

- For outdoor use. Front paints, paintwork materials for sports grounds and pools, walls and socles, roofing materials. In terms of performance, paints are suitable for extreme conditions, regular temperature changes.

- For internal work. The materials are intended for floors, walls, windows, interior items. It can be used only in dry rooms - such paints are not used outdoors.

- For wood. Such paints include antiseptic and fungicidal additives - from bacteria, fungus, mold, since wood products are more prone to decay.

- Auto paint. Paintwork materials of this type are used for painting a metal car body, have a rich palette, and have special wear resistance. They can be applied to rims, interior elements.

Composition

The basic composition of rubber coatings includes latex, which gives elasticity, strength, ductility. To ensure the desired properties, rubber resin (not all types), preservatives and antiseptic additives, colors (pigments) are introduced into the paint. To give frost resistance, antifreeze may be present in the composition. You can dilute the material with water, because it is a binder component. There is coalescent in the paint - a modifier that forms a film on the treated surface.

Some are trying to learn how to make rubber paint with their own hands. Of course, it will not work to give particularly durable properties to home-made paint, this is only possible under industrial conditions.Home craftsmen make material from silicone sealant, which must be diluted with a solvent and any dye (usually black, gray, brown) should be added.

to contents ↑Volume and form of release

Paint is produced in liquid form in cans, drums, buckets, sprays and aerosols. The latter option is more expensive, but very convenient to use. Paint weight may be:

- 1.2 kilograms (1 liter);

- 3.5 kilograms (2.5 liters);

- 6 kilograms (4 liters).

Larger volumes can be found on sale - 12, 14, 40 kg. Paint in cans is represented by volumes of 325, 390, 450, 520 ml.

Colors

White and black paints are considered universal and are most in demand among masters. White paintwork can be tinted in any shade, even in the most bizarre. Many manufacturers produce paint ready-made color shades - blue, yellow, red, green and many others (usually in the range of 5 to 17 tones).

For cars, there are paints and varnishes with unusual effects - metallic, flicker, mother of pearl, matte or glossy, with phosphors (luminous). To paint buildings from the outside, “with crumb” paint is often sold.

to contents ↑Storage and transportation conditions

Material in a closed jar or the remainder of unused paint should be stored in a tightly closed container at a temperature above 0 degrees, but not more than +40 degrees.

Short-term freezing during transportation is allowed (up to -20 degrees). After freezing, you need to keep the material warm for a day, then it can be used for its intended purpose.

Features, advantages, disadvantages

The strength of the material allows the use of paint on roofs, athletic fields, cycle tracks, floor coverings. The paint lasts up to 8 years without loss of quality and aesthetic properties. A unique opportunity to repair a separate area, applying a new layer only to the defective place - this is only available when using latex and acrylic coatings.

Rubber paint has excellent moisture resistance, therefore it is often used as a waterproofing layer. It can be used to paint walls, floors, and other surfaces in rooms with high humidity (in the bathroom, kitchen). Some types of material are used at all for processing the pool bowl, artificial reservoirs.

Other properties of coatings:

- Elasticity. Even those surfaces that are subject to friction, vibration, movement, do not crack after applying liquid rubber. Other paints under such conditions quickly burst.

- Ecological cleanliness. The composition of the material does not pose a risk to human health. Acrylic and latex are used even in the manufacture of children's products, and other components are non-volatile and do not emit toxins. You can work with paint even in winter, indoors.

- Resistance to temperature. After drying, the material forms a frost-resistant film, which does not deteriorate at temperatures of -60 ... + 50 degrees, that is, it can be used on the street.

The pros and cons of rubber paint are also worth a list. Advantages:

- the possibility of applying to any surface;

- simplicity of work, lack of need for a certain qualification of the painter;

- reasonable price;

- universality - suitable for external and internal works;

- good adhesion with the coating available on the base;

- the ability to work on rust;

- long guaranteed service life;

- breathability of the paint layer;

- resistance to UV radiation, no burnout;

- non-slip surface.

How long does the paint dry? Liquid rubber is very fast drying, some types completely dry in an hour. The disadvantages of the material include only the need for proper preparation, otherwise the paint may peel off.

to contents ↑Fields of application

What to paint? Areas of use for rubber paint are diverse:

- Front works. Rubber dye is bought to update the appearance of buildings, structures, foundations. Great for concrete, brick, stone, wood. The lining looks beautiful, and this cost item will not be large.

- Fences, house fences. You can paint the product with any fences inside the plot and around the perimeter.

- Roofing.Roofs made of ondulin, slate, rubber slate, galvanized steel are ennobled with liquid rubber. The operational life of the products will increase, asbestos dust from some types of substrates will cease to get into the air. Metal roofs will be reliably protected from corrosion, will not fade.

- Pools, walls and bottom of reservoirs. As a waterproofing material, rubber color is ideal for cladding such objects.

- Bathrooms, kitchens. The paint is fully consistent with safety requirements, moisture resistant, not subject to friction.

- Children's rooms and facilities for entertainment. The absence of toxic components makes coatings suitable for use for this purpose.

- Paving slabs. If painted with track material, the surface will no longer slip, which is important during rain. Tiles for many years will not lose their attractive appearance.

- Baths, saunas. Lack of toxicity, non-susceptibility to destruction, moisture resistance - properties that are useful when using paint on these objects.

Rubber paint can be used at sports facilities, farm buildings, gazebos, terraces, benches. The material will easily update the appearance of old furniture, broken interior items.

to contents ↑Rubber Coated Materials

Liquid rubber perfectly fits on most types of substrates - concrete, brick, metal, tile, natural and artificial stone, wood, MDF, OSB, drywall, plaster, putty, asphalt, polypropylene, polyurethane. It is possible to put LKM on other varnishes, paints without removal of the previous layer. Even on glued vinyl and non-woven wallpapers, this product can be applied without loss of properties.

For wooden surfaces, the material is also suitable because of the ability to inhibit decay - it has fungicidal additives. The paint does not crack at the joints of the genital lath, which move with temperature changes. Liquid rubber can be treated with products from any metals - ferrous and non-ferrous, from alloys.

Due to its properties, the paint can be used in places with special conditions:

- at high humidity;

- closed, poorly ventilated rooms, without windows;

- slippery surfaces;

- often cracking areas;

- places with temperature differences.

Preparation and application

When painting, it is important to strictly observe the technology, the preparation procedure and the main actions. This is very important, because otherwise there is a high risk of detachment of the material from the surface.

Cleansing

Preparation of the base is very important compared to the use of other coatings. First, they perform mechanical cleaning, removing from the surface:

- garbage;

- dust;

- mud;

- fungal plaque;

- mold.

If possible, remove all rust and previous coatings. Major defects must be completely eliminated. Cracks, chips, pits are putty, then sanded with sandpaper with fine grain. All protrusions are ground until they are completely removed - it is important to achieve a smooth surface.

to contents ↑After washing the product, metal and plastic are degreased. For this purpose, use solvents or ordinary soap, dishwashing detergent. If the surface is too glossy, it must be passed with a sandpaper to improve the adhesion to the paint.

Primer

Iron and other metal parts are coated with a special anti-corrosion compound before priming, then an insulating primer is used. Apply the soil with a roller, brush. If the base is too smooth, gently sand it.

Concrete, cement surfaces, and other porous materials must be treated 2 times with deep penetration primers. The tree is covered with silicone-acrylic primer. Other bases are protected with universal acrylic or latex primers.If the product will be regularly exposed to rain, snow, it is worth additionally applying a layer of hydrophobic soil.

to contents ↑Dyeing

The paint is applied with a brush, spray gun, roller. Perform 2 to 3 thin layers, each applied only after the previous one has dried. Drying time should be found in the instructions, usually 1 - 2 hours. The last layer is dried from 3 hours, but before use it is worth waiting 24 hours.

Tips for painting with liquid rubber:

- Perform painting work at a temperature of at least +5 degrees.

- In the corners, it is imperative to tint the base with small brushes so that the paint penetrates into cracks and cracks.

- Stir the paint often so that the mass is uniform.

- Do not paint buildings in windy weather, in a draft - waves may appear on the surface.

- Do not apply material on quicklime - the layer will immediately fall off.

to contents ↑

Paint consumption and surface care

Liquid rubber is quite economical. Consumption will depend on the type of substrate. For example, iron or galvanizing "consume" 250 g of paint per square meter. Up to 400 g of funds are spent on concrete, brick, plaster, on wood - 350 g. Consumption for painting slate above is 450 g, for application on previously painted substrates - 150 g.

to contents ↑You can start wet cleaning of the surface 7 days after the final drying of the paint. During this period, paintwork will find all the necessary properties. Chemicals are best avoided, but soapy water does not harm. Purification in the future is carried out as needed.

Manufacturers

Different companies produce domestic paints and varnishes - domestic and foreign, the choice is very large (can be found on any site, for example, kraski.ru). Usually foreign coatings are much more expensive, although they practically do not differ in properties.

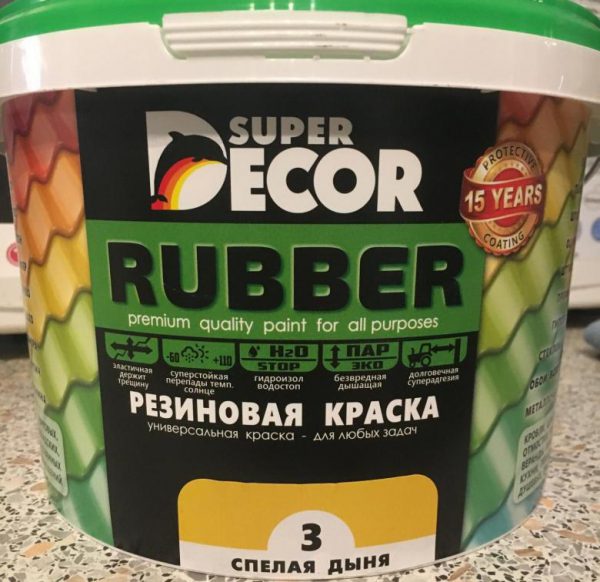

In the first place in terms of sales is Super Decor Rubber VD-AK-103, which is produced in Russia by Baltikolor. Super Decor is suitable for indoor and outdoor use, suitable for the pool, as it has high moisture resistance. Superdecor can be used for slate in order to improve aesthetic properties.

Other popular paintwork materials with similar characteristics:

- Dali (Dali) - antifungal, perfectly mask cracks, smoothes;

- Tikkurila (Tikkurila) - a high-quality line of products based on latex of various colors;

- MasterGood (Master Hood) - lays well on the base, creates a strong layer, represents an inexpensive alternative to tiles;

- Optimist F310 - finds application as a sealant, waterproofing for roofs, facades;

- Plasty Dip - liquid rubber in cans, is widely used for painting the car body;

- Prosperity - the brand produces VD-AK-103 paint, which is characterized by high hiding power and elasticity;

- Farbex (Farbeks) - universal paint, suitable for wood, OSB, metal, slate, tile, galvanizing, ondulin, plastic, aluminum;

- Maxima (Maxima) - the ideal paint for concrete, the finished coating will be elastic, moisture resistant;

- Prom Color (Promcolor) - used for all types of roofs, for swimming pools, paving slabs, recommended for wet rooms, dries in an hour;

- Ecoross - an excellent paint for concrete floors, used in parking lots, garages, warehouses;

- The chief technologist from Novbytkhim - suitable for any surfaces, even with plaster, gives a smooth, beautiful coating;

- Elast-R - the best option for seismically active zones, for repair work in houses before they shrink;

- Siltex Paint - the best wear-resistant paint, semi-matt material based on water and latex;

- Matte - car paint, gives a glossy layer to which midges and dirt do not stick.

Among the rubber paints, it is worth mentioning the brands Spider Web, Snezhinka, Petra, Zima, Lakra, Technoprok produced in Russia. All of them are adapted to the winter climate, so they will be an excellent choice in all weather conditions.