Metallic paint is a special composition designed to give the material a beautiful sheen. Most often, this type of paints and varnishes (primarily metallic spray paint) is used in the automotive industry.

- Differences between metallic and other types of paints

- Paint composition

- Types of paints

- Painting Features

- Training

- Dyeing Application

However, in recent years, metallic luster has also become popular in construction and repair work. The use of this type of paintwork has its own characteristics, which we dwell on in this article.

to contents ↑Differences between metallic and other types of paints

The main differences between metallic paint and conventional coatings are as follows:

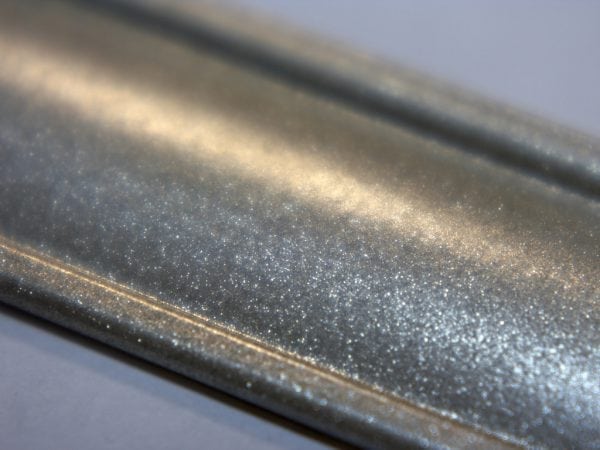

- The composition contains aluminum powder, due to which the material gains shine.

- Using ordinary enamel, painting the surface is much simpler. But the metallic should be applied perfectly evenly, since otherwise ugly stains cannot be avoided.

- Metallic is more resistant to corrosion processes, which is explained by the presence of aluminum in its composition.

- Plain paint is more prone to fading.

- Metallic to a greater extent prevents the heating of the cabin in hot weather (higher light reflection).

- Metallic looks more attractive.

- The cost of metallic is much higher in comparison with conventional coatings.

Paint composition

Let us dwell in more detail on the components of metallic paint:

- Pigment. It is a finely ground powder, due to which the paint acquires a given color. Also, the pigmenting substance can perform additional functions, for example, to protect the metal from rust.

- The connecting component. This substance is responsible for the retention of pigment on the treated surface. The bonding element also makes the coating smooth and even.

- Solvent. Due to dilution of the paint with a solvent, it gains fluidity, which allows the composition to be applied to the surface. Moreover, the manufacturer’s task is to make the solvent evaporate as quickly as possible, since it is harmful and does not carry any other functions besides dissolving the composition.

- Aluminum chips and dust. Another name for the substance is aluminum powder. As mentioned above, aluminum is responsible for giving the coating a shine. The reason for the glare is the ability of aluminum powder to reflect light, which creates the impression of a glow of the coating.

Types of paints

There are several types of paints and varnishes on sale:

- In aerosol cans. Such compositions can be offered either in finished form (paint and varnish are already mixed), or in a separate version (varnish and paint separately). Both types of packaging have the right to life, but practice shows that working with separate cans allows you to achieve better results, as the surface will turn out to be more uniform. In this case, the first method is more suitable for beginners, as it is easier.

- Acrylic composition.Such paintwork is used both for tinting paint, and as an independent coloring matter. Acrylic has many advantages, including good adhesive qualities in relation to any painted surfaces, as well as a wide selection of colors. It is also worth noting the safety of the solution, since there are no organic solvents harmful to human health.

- Powder paints. This is a relatively recent invention of the chemical industry, but has already become quite popular. The reasons for the success of powder formulations lie in their consumer qualities: economical consumption, simple application technology, environmental safety, a wide selection of colors.

- Car paints. This is the most common metallic paint option. You can purchase such a composition in any car shop. The application of paint is fraught with technological difficulties: as mentioned above, it is necessary to paint very evenly. However, if the work is done correctly, the surface will serve for many years, being resistant to mechanical stress and ultraviolet radiation.

Advice to the consumer! Aerosol spray can is the easiest way to apply paint.

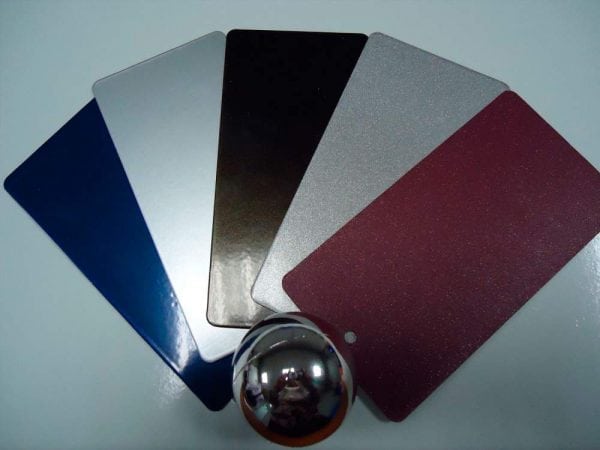

It is also worth mentioning some of the nuances associated with the choice of color:

- White color allows you to get the effect of shining pearls - the coating seems to glow from the inside. Such a surface looks very elegant.

- Black color looks deep and saturated. The same effect applies to any other dark tones.

- Red, green, blue are bright colors, and if they are implemented in a metallic style, the visual effect is further enhanced.

- Gray metallic looks restrained and solid, although the material painted with such a paint does not look as bright as in the case of silver.

Painting Features

The technological process of painting may vary depending on the type of paint material chosen, however, the surface preparation process is always the same. Moreover, it should be noted that the quality of the resulting coating directly depends on the thoroughness of the preparatory process.

Training

Instructions for the work:

- Remove old paint, if any. We clean the surface of dust, dirt, chips and other debris.

- We inspect the base for obvious defects (scratches, chips, etc.). We cover the defects with putty.

- After the putty has dried, take sandpaper and grind the surface to the maximum possible smoothness.

- Again we clean the surface of dirt and dust and apply a degreasing composition. When it comes to metal or plastic products, the best option is anti-silicone fluid. Other bases can be treated with white spirit.

- We apply a primer in 2-3 layers. The primer composition will protect the base from the negative effects of the environment, level the surface and create conditions for high-quality adhesion (i.e. adhesion of dissimilar materials). The primer should be selected based on the type of base, but there is a rule that it should be combined with the selected paint. It is best if both coatings and primers are from the same manufacturer.

Dyeing Application

The application of paint from the spray can is relatively simple: the movements must be very smooth, and the spray gun must be kept at a distance of 25-30 centimeters from the surface.

The technology of applying two-component varnish is not so widely known. The work is organized as follows:

- First, create a base layer. Minor defects are allowed, as another layer will be applied on top, which should already be very uniform.

- The varnish is applied in 2-3 layers (the specific number of layers depends on the type of material and type of varnish).

Note! It is extremely important to prevent the base from overdrying, so in this case it is impossible to achieve high-quality coating.

Separately, it is worth mentioning the so-called apple. A defect is the appearance of round or striped spots on a metal. Malignancy occurs as a result of improper preparation of the base (for example, the wrong choice of primer) or a faulty spray gun. Also, the cause of the appearance of "apples" may be the application of paint on a damp surface. You should be very careful about all stages of the process, because in case of an error, you will have to repaint the surface with very expensive coloring material.