The use of paints with increased heat resistance is justified in production, in a number of extractive industries. Such paints and varnishes help protect metal products and extend their service life. An example of a product is organosilicon enamel KO-8101 and similar products.

- Heat-resistant enamels series KO - description

- Differences of enamels series KO

- KO-8101

- KO-8104

- KO-8111

- KO-870

- KO-868

- Enamel Characteristics

- Surface preparation

- Material preparation

- Dyeing

- Security

- Storage conditions

Heat-resistant enamels series KO - description

Organosilicon paints, varnishes, enamels have a huge advantage over others in heat resistance. Obtaining a heat-resistant material is achieved by creating a macromolecule of an organosilicon compound in which the bonds between silicon and oxygen atoms are very strong. Also, the desired properties of the agents are given by various targeted additives:

- anticorrosive substances;

- acrylic varnishes;

- carbide layers;

- epoxy resins;

- ethyl cellulose etc.

To achieve the desired color, special pigments are introduced into the composition. Their base is also heat-resistant, so the color does not lose brightness even at high temperatures. Most often, paints are applied to metal, because they give surface protection against corrosion. But enamels can also be used on concrete, brick, if they are used in an aggressive environment.

Features of enamels are as follows:

- withstand heating up to +600 degrees;

- resistant to steam, moisture, precipitation, sunlight, a number of chemicals (chlorine, etc.);

- do not require thermal quenching;

- have excellent adhesion to surfaces;

- easy to apply;

- can be applied in external and internal works;

- after complete drying non-toxic;

- provide decorative qualities.

to contents ↑Now, such paints and varnishes are widely used by oil and gas production and processing enterprises. They are also used in power plants, marine enterprises, they make the coloring of heating pipes, furnaces, reinforced concrete structures, fireplaces, ventilation.

Differences of enamels series KO

In the KO series, several enamels are produced that have much in common, but also have a number of differences in description and characteristics.

KO-8101

Corrosion-resistant enamel KO-8101 is used at temperatures of -60 ... + 600 degrees, mainly for painting exhaust systems of cars, for applying to pipelines, furnaces, heating systems. The goal is to protect against rust and give an attractive appearance to products.

Enamel colors:

- the black;

- Gray;

- blue;

- green;

- white;

- red;

- beige etc.

The tool is one-component, does not require special preparation before application. Priming before using enamel is also not necessary.

to contents ↑KO-8104

The scope of this tool is similar - it is used to protect metal products from corrosion, can withstand temperatures up to +600 degrees, but for a shorter time. Therefore, most often paint is used in mechanical engineering, for application to pipelines. It is also possible to process products made of concrete, stone, brick, other mineral materials. Product colors - green, gray, blue, red brown, blue, yellow and others.

to contents ↑KO-8111

This tool can be used to protect steam, gas turbines, generators, heat pipes.KO-8111 stands out from other organosilicon enamels by its ability to not react for a long time to the action of various chemistry, and not to lose properties in an aggressive environment. Also, this material can be applied to surfaces at sub-zero temperatures.

to contents ↑KO-870

This enamel almost does not differ in properties from the previous ones, but has higher resistance to water. Therefore, it can be used where there is contact of products with moisture, there is an increased humidity. The tool has proven itself in the operation in the open air, where the surfaces are subject to the direct action of precipitation. Scope - concrete and brick fences and other products, equipment, gas and steam turbines, generators. Like analogues, the material is available in a variety of colors.

to contents ↑KO-868

It is used where not only high temperature, but also high humidity acts on the surface. It is acceptable to apply the product on concrete, artificial stone, brick, but the main material for protection is metal. Most often, enamel is used for application on:

- pipelines;

- construction equipment;

- reservoirs;

- tanks;

- hydraulic structures;

- agricultural machinery.

Also, the material can be applied to asbestos-cement surfaces. It lays well even at low temperatures, withstands up to +600 degrees.

to contents ↑Enamel Characteristics

Technical characteristics of heat-resistant enamels are indicated in the certificate of conformity, series passport. They are presented in the table below and include all the main parameters of the funds.

| Metric Unit | KO-8101 | KO-8104 | KO-8111 Color / silver, gray |

KO-870 | KO-868 |

|---|---|---|---|---|---|

| The proportion of solids,% | 40 | 40 | 45/38 | 45 | 50 |

| Viscometer VZ-4 viscometer with a nozzle of 4 mm, s | 25 | 25 | 27/27 | 24 | 25 |

| Drying time at a temperature: +20 degrees, h | 2 | 2 | 2/2 | 2 | 2 |

| +150 degrees h | 0,5 | 0,5 | 0,5/0,5 | 0,5 | 0,5 |

| The degree of milling, microns | 60 | 60 | 40/40 | 60 | 60 |

| The hardness of the coating on the TML device, cu | 0,4 | 0,4 | 0,4/0,4 | 0,4 | 0,4 |

| The resistance of the coating at a temperature of +20 degrees to action: -water, h | 24 | 96 | 24/24 | 100 | 48 |

| - mineral oil, h | 24 | 24 | -/24 | 48 | 24 |

| - gasoline, h | 24 | 24 | -/24 | 48 | 24 |

| Fortress on impact with the U-1 device, cm | 40 | 10 | 40/40 | 40 | 40 |

| Heat resistance at +600 degrees, h | 5 | 3 | 3/3 | — | 3 |

| Resistance to salt fog, h | 96 | 96 | 100/100 | 96 | 100 |

| Adhesion points | 1 | 1 | 2/1 | 1 | 2 |

| Consumption per 1 square. m at temperatures up to +600 degrees, g / sq. m | 130-150 | 130-150 | 130-150 | 130-150 | 130-150 |

| Consumption per 1 square. m at temperatures up to +150 degrees, g / sq. m | 150-180 | 150-180 | 150-180 | 130-150 | 130-150 |

The appearance of the film of any enamel should be smooth, uniform, matte or semi-gloss. When exposed to varying temperatures (-60 ... + 600 degrees), the film should be free from peeling, cracking.

to contents ↑Surface preparation

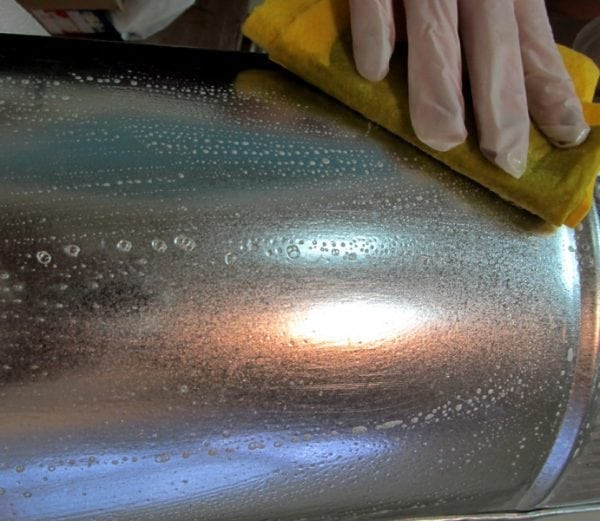

For all described paints there is a general instruction for preliminary preparation of surfaces. To improve adhesion to the base, the following preparatory measures are taken:

- clean the painted product from dirt, dust, salts, grease and other pollutants;

- remove all available rust, as well as paint that is poorly adhered to the surface (all or individual sections);

- purification to the degree of St3, SA2-2.5 according to standards;

- Before painting work, degrease the base with solvent or xylene, start painting no later than 6 hours in an open area, and in a day in an indoor environment.

The main condition for a qualitative result is the presence of a completely dry and clean base, then the material will lie flat, have good adhesion.

to contents ↑Material preparation

Enamels KO-8104, KO-8111, KO-868, KO-870 are prepared according to the same rules. Before use, the material must be thoroughly mixed in order to achieve uniformity and eliminate sediment. After they do not start staining for another 10 minutes - this is necessary for the release of air bubbles. Before work, carry out control measurements, the indicators should be as follows:

- viscosity during pneumatic spraying - 17-25 s;

- airless spray viscosity - 30-45 s;

- viscosity for application by brush, roller - 25-35 s.

The indicator is measured with a VZ-4 viscometer with a 4 mm nozzle, while the temperature is close to room temperature (+20 degrees). If the viscosity is exceeded, enamel is diluted with xylene, orthoxylene, but not more than 30%. When you need to take a break in the painting, the container with enamel is tightly closed. After stirring the material again and incubated for 10 minutes.

to contents ↑KO-8101 paint is prepared in the same way, the difference is only in the index of working viscosity during pneumatic spraying. It should be 15-17 s under the same initial conditions. For dilution, xylene or solvent is used.

Dyeing

For enamels KO-8104, KO-8111, KO-868, KO-870, the staining process is carried out as follows. Application is carried out in 2 layers with a roller, brush, pneumatic spray, airless spray. It can be applied in an electrostatic field. Conditions for work:

- humidity - up to 80%;

- temperature - from -30 to +40 degrees;

- when working in cold conditions, it is important to ensure that the surface temperature is at least 3 degrees above the dew point (this is required to prevent the appearance of ice crusts, frost);

- the distance from the nozzle of the sprayer and the base during pneumatic spraying is 20-30 cm, pressure is 1.5-2.5 kgf / sq. cm, the diameter of the nozzle is 1.8-2.5 mm.

On hard-to-reach spots, seams, edges, enamel is applied with a brush. The metal surfaces are painted on 2-3 layers (cross), drying each layer for 30-120 minutes (the exact time depends on the temperature, the basis is checked "on stick"). If the temperatures are minus, the time may increase by 2-3 times. Concrete, cement, plaster surfaces are painted in 3 layers.

Drying of the final coating is done for at least a day at a temperature of +20 degrees, the final hardening is observed when using products. It is possible to do hot drying - first withstand surfaces at room temperature for half an hour, then raise the temperature by 3.5 degrees / minute, and so on for an hour. If you intend to use products under the influence of oils, gasoline, salt solutions, other substances, you should perform hot drying for 15-20 minutes at 250-400 degrees. The thickness of the finished coating is usually 40-50 microns. The number of layers is determined by the application method and the total thickness of the coating. It is possible to start up the work, transport the products after painting, after 3 days.

to contents ↑Enamel KO-8101 has some differences in the drying process. At a temperature of +20 degrees, coatings should be dried only 2 hours, and not 24 hours, as is the case with other means. Full hardening occurs during operation of the products during heating. The hot drying technique is similar.

Security

When working with any paint, safety precautions should be observed. The materials are toxic because solvents are present in them. The latter belong to the 3rd hazard class, in the working area of MPC for them - 150/50 mg / cubic meter. m. It is better to stain products in open areas and make sure that they are well ventilated. Hands should be protected with special pastes or gloves, a respirator should be worn on the face.

Do not work in pits, wells, enclosed rooms unless ventilation is equipped there and personal protective equipment is not available. In such conditions, a gas mask should be used. Solvents also cause a high fire hazard of enamels, so there should be no sources of heat and fire in the working area. In case of fire, fire extinguishing is carried out using foam, sand, finely sprayed water.

to contents ↑

Storage conditions

Enamels KO-8104, KO-8111, KO-868, KO-870 are stored in a closed container, avoiding the sun, away from heat and moisture at -50 ... + 40 degrees. For enamel KO-8101, the conditions are similar, but the temperature is -35 ... + 40 degrees.