Modern metal primer-enamel is used to protect and paint various metal surfaces. It is designed to cover both clean and rusty objects. Enamel protects the coating with a thickness of dense rust up to 100 microns.

Enamel primer possesses qualities of anticorrosive primer, decorative enamel and rust converter. The main purpose of such a paint is to cover surfaces that cannot be completely cleaned from rust. For example, this applies to very large objects of irregular shape.

to contents ↑Composition

The composition of the soil-enamel includes pigment suspensions, fillers in epoxy resins, organic solvents and various target additives. The main active ingredients of enamel are stabilizers of products formed as a result of corrosion, as well as corrosion inhibitors. These substances form a waterproof and chemically resistant coating on the surface to be painted.

Positive qualities of primer-enamel

- quick drying;

- high resistance to salt water and adverse atmospheric factors and mineral oils;

- resistance of the enamelled surface to large temperature differences (from -50 to +100 degrees);

- the presence in the composition of high-quality anti-corrosion pigments that prevent further corrosion progression;

- high adhesion to metal, which does not require the use of a primer;

- high quality dispersion pigments providing excellent decorative characteristics;

- simplicity of operation;

- the possibility of application by pneumatic spraying;

- low consumption, which ranges from 80 to 120 ml / m2, depending on the need;

- high painting characteristics;

- the possibility of painting at temperatures up to -10 degrees.

Rules for the use of primer-enamel to reduce consumption

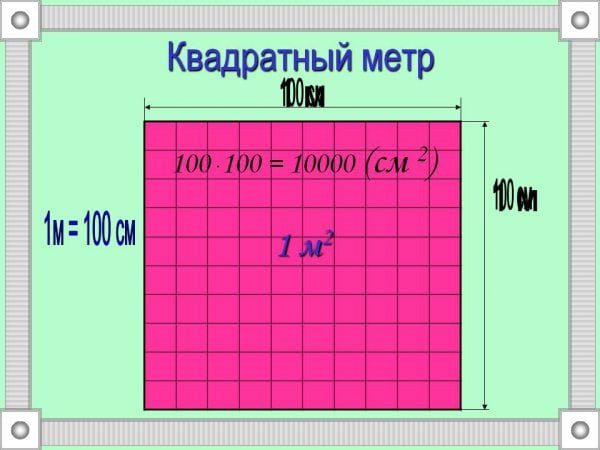

Before using the paint, it is necessary to calculate its consumption on the surface to be painted. To do this, you need to know the enamel consumption rate per 1 m2, which is indicated by the manufacturer.

Just before use, the primer should be mixed well. Next, the surface is prepared, which includes cleaning the metal surface from dirt, dust and a layer of rust. Also, if necessary, the surface is degreased.

If the metal coating was previously painted with oil or alkyd paint, then it is better to clean it to a dull appearance. In addition, in order to further reduce paint consumption, experts recommend making a trial stain. This procedure will help to see the place of exfoliation and swelling, and if necessary, remove them.

It must be remembered that the primer-enamel on metal or wood can not be applied to a surface that was previously painted with a nitro-paint coating. To reduce the consumption of enamel, it should be applied at a temperature of -10 to +30 degrees.As a tool, you can take an ordinary brush or roller. However, pneumatic spraying is considered the most economical method of applying white enamel.

Before starting coloring with this method, it is recommended to dilute the enamel with the help of special solvents or xylene. With their help, you can wash the tool or random spots. It is desirable to apply enamel in two layers, making gaps between them for at least an hour.

After applying the primer-enamel and drying it, any kind of paint can be applied to the surface. Subject to all these rules for the application of primer-enamel, the consumption will be minimal within 80 ml per 1 m2, which is the most profitable from an economic point of view.

Scope of application of white enamel on metal:

- painting fences, metal structures, garages and other objects that are operated in severe atmospheric conditions;

- painting of rusty surfaces of automobiles, such as wings, underbody and so on.

Thus, the primer-enamel is a reliable coating for metal structures with a rust layer. Such enamel will provide maximum protection against corrosion and create a primer layer for subsequent application of paint.