Aluminum objects are very common in everyday life, but if they lose their appearance, then painting aluminum can be a serious problem, especially if you are going to make it at home. The complexity of working with such a material is explained by its oxidation upon contact with air. This process forms a coating, which is very difficult to level. Therefore, it is extremely important to follow the instructions for painting aluminum surfaces, otherwise your efforts will be practically useless, and the color will not last long.

In production, aluminum is painted under special conditions that prevent oxidation, and special components are added to paints. It is impossible to do this at home, so you need to learn from the experience of those who did this before you.

to contents ↑Staining methods

There are two main ways to paint aluminum products: with anodizing and aniline, as well as without it, but using metal enamel and primer. Thanks to these methods, you can paint aluminum products with your own hands right at home.

If you have not previously encountered anodizing, this is a chemical process that is performed so that aluminum does not oxidize and the paint normally lays on its surface. It is this procedure that guarantees the highest quality coloring both at home and in industry. However, without it, you can achieve acceptable results if you follow all the instructions. After all, anodizing large objects with your own hands is a very, very difficult process.

to contents ↑DIY anodizing

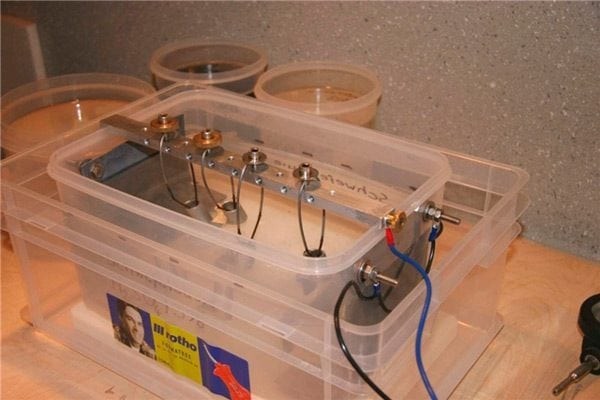

Painting of aluminum surfaces using anodizing is as follows. You will need:

- for electrolyte solution - soda and salt;

- aluminum cookware;

- current source;

- sandpaper;

- aniline and vinegar;

- degreasing agent.

First we need to make an electrolyte. In order to prepare salt and soda solutions. To do this, mix them in one vessel in a proportion of 9 parts of salt to 1 part of soda. Mixing must take place in a glass dish!

We process the product to be painted with sandpaper and degrease its surface. After that, it should be dipped in water, trying not to touch the surface of the profile with your hands. In aluminum dishes, you need to fill in the electrolyte solution, put the painted object there too. Next, connect the current source with the positive pole to the product, and the negative to the dishes. Leave it for 2 hours.

After that, you can proceed to painting with aniline dye. To prepare it, add 1 ml of vinegar, 15 gr. To a liter of water. dye and heat about 75-80 degrees.

to contents ↑Next, in this solution we put the object of staining for about a quarter of an hour. Now you know how to paint anodized aluminum.

Alternative technology

How to paint aluminum without anodizing at home? You will need:

- sandpaper;

- primer;

- epoxy or acrylic paint for metal (aerosol is more suitable than standard powder paint if painting takes place at home);

- degreasing agent.

First, you need to properly sand the product. Next, the profile should be degreased. After this, it is necessary to begin priming the surface of the profile as quickly as possible. After a full primer, you can begin to paint. It is better to use an aerosol.

After painting, leave the profile to dry for 6 hours, after which its surface can be covered with an additional layer of varnish. That is how the painting of aluminum in houses ends, if you do it yourself.

But there is an even simpler way to paint your home! To implement it, you just need to grind the product well and then degrease it. After you need to apply a special enamel paint on it. Carefully follow to accurately follow all the instructions on the enamel jar! Painting will be finished after drying.

to contents ↑Powder coating

If you have the opportunity to attract some production tools to paint, then an excellent option for you will be to give aluminum a new color with powder paint.

This method of staining requires processing the part with a special solvent that will not leave previous layers of paint on the subject. Next, powder coloring matter is applied. This is done evenly and accurately so that the color is saturated and constant.

Immediately after applying powder paint, the part will not seem too perfect, but then the item must be placed in a special industrial heat chamber.

There, the part and the coloring powder are heated to a high temperature, so that the powder begins to melt, evenly painting the surface on which it is applied.

It is this method of painting aluminum parts that is the most durable and reliable, because such paint is of high quality. But to carry out a similar process at home is more than difficult.

Painting surfaces of non-ferrous metals is a difficult process, but if you approach it competently, it is easy to carry out even at home. The main thing is compliance with the rules!

Powder coating of aluminum is the most effective method of obtaining a stable polymer coating on the surface. This method of painting provides metal structures with an attractive appearance, without smudges or sag. Also, powder dyes have high electrical insulating and shockproof properties, protect the surface of the product from temperature extremes from -60 ° C to + 150 ° C. This technology of painting surfaces is a worthy alternative to applying liquid paints and varnishes and even has several advantages. For example, the powder coating does not fade in the sun, and the product always has a bright saturated color.

Such a solution as 9 parts of salt and 1 part of soda pour yourself in the back seat.