Under the patina understand the signs of aging on various interior items, household items or materials. Artificial aging - patination - is actively used by designers, because it gives the products a noble vintage look, antiquity and high decorativeness. There are methods on how to make a patina with your own hands without extra costs - for this you only need to purchase the right material and get familiar with the technology.

- Features of the patination technique

- Tools and materials

- Varieties of patina, composition and consistency

- Stain

- Wax

- Acrylic

- Bitumen

- Oil

- Shellac

- DIY patina on wood

- Preparatory stage

- Stain patina application

- Classic way

- Craquelure technique

- Artificial Scuffs

- Patina on metal: step by step instructions

Features of the patination technique

Initially, the concept of “patina” was characterized only by a darkened coating on copper products - over time, the oxide film gave the metal an “aged” appearance. Later, the word began to be used to reflect the vintage look of other materials - wood, bronze, iron, gypsum. Recently, "antique" houses, cottages and even city apartments are being made out. Artificially aged wooden furniture with “antique” fittings looks especially stylish.

Modern technology helps to age - patinate - any materials. Industrial methods are difficult for home use, but there are various patinating compositions on sale that allow you to increase the age of materials in a simpler way. They help simulate the natural color change of products by applying special coatings. When patinating, familiar paints are replaced with specialized formulations without affecting the internal structure of wood or other material.

to contents ↑The simplest method of aging is to rub the wax into corners, relief protrusions, and the edges of the product. The result is the effect of “age-related” surface changes, ideal for decorating a room in retro style. Such a coating also has a practical function - it protects the base from external influences, gives water-repellent properties. If the result is unsatisfactory, the home patina can always be removed without significant harm to the product.

Tools and materials

Before work, you need to prepare all the necessary supplies - paint with the aging effect (with elements of bronze, silver, gilding), ordinary paintwork, if you plan to repaint the product. Instead of paint, you can apply wax, stain, shellac or mastic, depending on the chosen option for patination.

Other process components that may be required:

- brushes of different sizes;

- roller (for large surfaces);

- sandpaper;

- primer;

- furniture or metal varnish;

- rags to remove excess paint;

- cotton and foam swabs.

Some masters additionally purchase metal powder if the effect of the paint seems insufficient: it is usually used to artificially age metal fittings. There are also ready-made kits for patinating and antique restoration on sale - “Patina Verde Green”, “Patina Gold”, “Idea Patina”. Most of the tools included in the sets are suitable for various materials - gypsum, metal, wood.

to contents ↑Varieties of patina, composition and consistency

Depending on the idea, using patination, you can give different effects to surfaces:

- fragmented aging;

- full coverage;

- craquelure.

According to the consistency, the working compositions for patina are as follows:

- thick - they resemble pasta, which is used in the processing of wood for coloring in yellowish or reddish shades, close to gold;

- liquid - made on a water or polymer basis, give the product a radiance, ennoble its appearance;

- facet varnishes - allow you to create an aged surface due to the formation of a network of cracks.

For processing wood, metal or other materials, compositions are used on a variety of substrates, which are unequal in the durability of the finished coating and the degree of adhesion to the substrate. The most popular are stain, wax, acrylic paint, bitumen, oil, shellac.

to contents ↑Stain

The use of stains is the easiest way to artificially age a wooden surface, so it is the most popular. Stain ennobles wood products, gives them a sophisticated look, helps to “make” more expensive wood from cheaper species. Means of this group contribute to protecting the tree from decay, colonization with fungi and mold, enhance moisture repellent properties.

Typically, product soaking involves pre-brushing - removing soft wood fibers with a strong brush, while stiff longitudinal fibers remain in place. Brushing is required to provide a more pronounced patina effect. After staining, products are often covered with wax or shellac primer. The range of colors when using stains is limited to dark wood shades, and it will not be possible to apply gilding, silvering or other metallic tones.

to contents ↑Wax

Often, wax patins in the form of a water-based paste are used as a topcoat. They are prepared by combining natural wax and metal dust. There are also colorless compositions on sale, after applying which a beautiful pearly shine remains.

The properties of the wax patina are as follows:

- Helps simultaneously emphasize the structure of the tree and tint it;

- it is easy to apply, slowly dries, it is easy to grind, so you can work with it in a mode convenient for the master;

- most often used for small areas, ideal for oak, ash;

- has different shades - silver, brass, bronze, gold, iridescent tones;

- beautifully highlights carvings, patterns, drawings, suitable for embossed and textured plates, cracks using the craquelure technique;

- It has high adhesion to wood, plastic, which is coated with MDF;

- applied with a rag or sponge, polished and dries within 24 hours.

Acrylic

Acrylic patina is a universal composition for wood, gypsum, metal. This material has a water base, but allows you to create a very resistant coating having excellent adhesion to surfaces. After application, the resulting film protects the material from decay, the growth of microbes and fungi.

The technology of acrylic patination is very simple, even a beginner can cope with it. Acrylic patina can treat the entire surface or part thereof, individual protruding elements. To give the base an original look, you can combine the compositions of different colors. There is also an option to apply different patina tones in several layers to get a unique effect, a complex color ornament. The choice of shades of acrylic is very rich - there are both metallic and classic tones.If necessary, this type of patination is well combined with varnishing, decoupage, conventional staining.

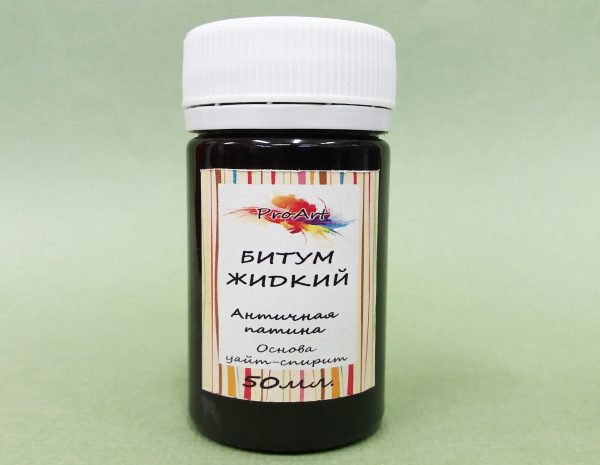

to contents ↑Bitumen

The structure of this building material helps to give the tree a special look, to carve out carvings, indentations and relief ledges, faces. After applying bitumen to the wood, the excess is removed with a solvent, and the absorbed composition creates the effect of antiquity (the product will have a dark color).

to contents ↑Bituminous patina is made on the basis of concrete polymer, turpentine, white spirit and is not considered a finishing material. After drying, the patinated surfaces must be covered with shellac to fix the result, otherwise it will not last long.

Oil

Oil patina is suitable for wood and metal. It does not hide the natural shade of the material, favorably emphasizes the pattern on wooden surfaces. By properties, the oil resembles a wax patina - it is easy to apply, it dries slowly. You can not use such compounds in the decoupage technique, since they dissolve the paper.

Shellac

By itself, this material has a yellowish or brown-red tone, which will become darker as the number of layers increases. It can be used in isolation or in combination with decoupage, becomes an intermediate or finish coating. When working with shellac, a brush or sponge is used.

to contents ↑DIY patina on wood

The patination process is simple and quite feasible at home. For work, it is better to choose wood species of high density that are immune to changes in humidity, or use MDF, particleboard.

Preparatory stage

First you need to carry out brushing - exposure of hard wood fibers before patina, tinting, varnishing. The method reproduces the natural aging of the tree, but at an accelerated pace. The surface is treated with a wire brush or coarse-grained emery paper, as a result of which hard fibers are removed. Then the base is wiped with a degreasing compound. Under acrylic paints or for staining, the tree is not brushed, but only cleared of all kinds of contaminants. If there is already varnish or other coating on the surface, it must be removed with sandpaper.

Particleboard, MDF boards have a homogeneous structure, unlike wood, so their preparation has features. To give abrasion, the surface can be carefully treated with fine sandpaper, but the most effective technology is the most complex:

- applying a barrier soil to enhance adhesion of the top layer of the plate to the patina;

- after drying - the application of a polyurethane primer, which will become the basis for the patina;

- grinding the created coating with sandpaper to reproduce the wood structure;

- proper patination.

Stain patina application

Soaking is ideal for classic-style furniture. The color of the products will become darker than it was originally. The procedure is as follows:

- Apply water-based stain to the facades, covering the entire part. You can choose any color - walnut, mahogany, oak, beech or other.

- To wipe part of the composition with a soft sponge in such a way as to give an aging effect (mainly from the middle zones). The border, thread, milling elements, cracks should be left darker.

- Allow the composition to dry, then apply a second layer of stain of a similar shade, but not on a water, but on an alcohol basis.

- As the product dries, perform a layer of shellac. If you want to enhance the vintage look, you can additionally erase the antique wax.

Classic way

Classical patination is based on the use of acrylic, wax, bitumen, oil.You need to choose the material of a suitable tone - wood, metal or ordinary. The technology resembles simple painting. First, a layer of material for patination is applied to the base, then its excess is erased or shaded more carefully. The second layer in this case is performed using shellac.

Also, standard technology may involve such actions:

- apply a patina of a dark shade;

- give the product a little dry, make another layer of the material in a lighter tone to emphasize the dark pores;

- instead of a light tone, you can take gold or silver, if we are talking about furniture in a classic style;

- as the sand dries, sand the base with fine sandpaper to create a worn effect;

- fix the result with shellac or acrylic varnish, choosing a matte finish.

to contents ↑

Craquelure technique

This technique allows you to "draw" a network of cracks on the surface of the product, which provides enhanced decorative effect. For craquelure use a special varnish with the same name on the packaging, which is able to crack after drying. The procedure will be as follows:

- the surface is treated with a primer, a brush and sandpaper are not used;

- apply craquelure varnish, choosing the composition that is necessary in color (if it is transparent, you can first apply acrylic paint, and then varnish);

- perform a very thin layer of matt water-based paint, acting carefully so as not to spoil the texture.

to contents ↑If necessary, cracks can be wiped with bitumen mastic to darken them, but only after the coating has completely dried (after 1–2 days). When cracking the film, the product will become aged. To fix the result, it is permissible to apply a layer of shellac.

Artificial Scuffs

This method is well suited for wood and MDF, goes well with decoupage technique:

- paint for patination of dark tones paint the surface of the product;

- after the edges have dried, the carved elements are covered with a layer of paraffin;

- apply on the subject a second layer of patina of a lighter shade or metallic tone;

- sanding the surface with sandpaper;

- coat the product with stain or wax, or with a transparent matte varnish.

Patina on metal: step by step instructions

Often produce patination of parts that are exposed to heat during operation - the external parts of the barbecue, fireplace elements, as well as furniture fittings, various corners and trim. In addition to increasing attractiveness, such actions help protect surfaces from damage and rust. The most popular metal patinings are gold, silver and white.

To work, you will need:

- acrylic paint;

- a set of pieces fallen;

- synthetic brush;

- alcohol;

- glue for shed;

- finish varnish for paly.

First you need to degrease the metal part with alcohol, wiping it with a rag. Using a brush, paint the surface with acrylic paint, applying it in 2 layers, and after drying, grease the base with glue and randomly lay out the pieces of sweat, gently press them with a brush. Then you need to remove its excess from the edges of the product. It is important that the material does not completely cover the surface and that areas of paint shine through in different places. At the end of the work, the part must be varnished.

The patina for wood and metal will serve as an excellent design technique, give simple products nobility and special charm. Performing patination is easy and very exciting - everyone should try!