A feature of barbecues is that they are most often located in the open air, and at the end of their use they are not always cleaned in a secluded place. Therefore, after their installation, you need to think about painting. Regardless of whether they are bought in a store, or made by their own hands, they need to be painted, since unpainted metal under the influence of adverse environmental factors undergoes corrosion. For the second option, this procedure is considered mandatory.

- Features of heat resistant paint

- Types of heat-resistant paint

- The process of painting the barbecue

- Application of organosilicon composition

- Applying acrylic paint

The question of how to paint the brazier must be approached seriously and responsibly. Coloring substances should correspond not so much to the taste and aesthetic preferences of the owner as to the requirements imposed on them.

Criteria to which barbecue paint should meet:

- The coloring agent should guarantee reliable protection against the appearance of rust, and therefore serve as a barrier against changes in air temperature, exposure to humidity and possible atmospheric precipitation on hot metal.

- It should have high refractoriness, not melt, be heat-resistant (when buying it, you need to pay attention to whether there is an indicator in the instructions (up to +500 C, or up to +800 C).

- Since the design is used for cooking, its coating in the process of heating should not emit toxic substances hazardous to human health, and do not react with other substances.

Therefore, experts recommend paying attention to heat-resistant coatings.

to contents ↑Features of heat resistant paint

- Withstands temperatures up to 800 C.

- Its deposition on metal is quick and affordable.

- It is desirable to pre-coat the painted surface.

- The tool does not adversely affect human health, so they can be painted not only the outer but also the inside of the product. Although staining the inside in rare cases gives the expected effect.

- Laboratory results have confirmed that toxic substances do not evaporate from the painted surface.

- A diverse color palette allows you to choose bold and original solutions, for example, red. But still, most owners prefer traditional black, as soot on it will not be so noticeable, and it will always look like brand new. Many people choose shades of gray for the frypot, if it is organically combined with the surrounding design.

- Coloring agents are liquid and dry. Liquid paint is applied over the primer, and dry after application requires hardening in a special furnace. Under the influence of high temperature heating the frypot, the coating adheres to the surface, which ensures its high fire resistance (for example, S54 paint made on silicone based) The first 10-15 minutes, the product is recommended to be protected from dust, and used no earlier than in a day. At home, it will be difficult to carry out such a procedure, so it is often used in production.

If the structure is not made of metal, but is made of brick or stone, then it is coated with a special refractory varnish that is resistant not only to high temperature, but also to atmospheric effects. Waterproof acrylic varnish will be very appropriate in this case, the surface with such a coating will be easy and convenient to wash and clean in the future.

Heat-resistant varnish KO-85 will be a more economical solution, but in especially frosty winters, cracking may occur. Modern super-resistant impregnations have recently also become popular. The oils included in them make them resistant to low temperatures, but numerous reviews by the owners indicate that they need to be periodically updated.

to contents ↑Types of heat-resistant paint

- Organosilicon enamels and varnishes of the type:

- enamel coatings of grades KO 8101, KO8111;

- varnishes KO / 08, KO / 815;

- organo-silicate compositions, for example OS 12/03.

They withstand temperatures up to +500 C, and their composition is resistant to high humidity, and protects the metal from destruction. They can be applied to metal, and other surfaces of the frypots.

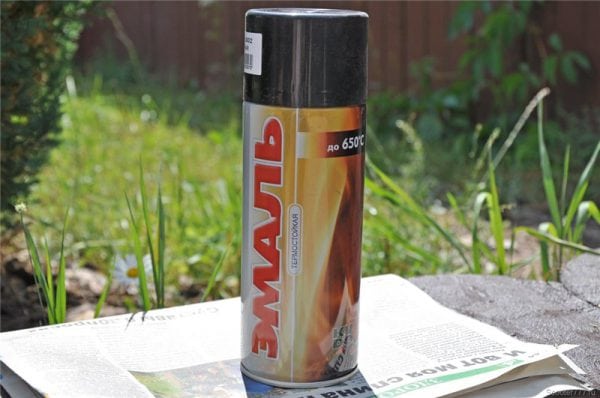

- Special acrylic compositions designed for long-term effective operation at temperatures up to + 650 ° C, and short-term use up to + 800 ° C.

Aerosol cans are especially popular in this group of coloring agents. Their undoubted advantage is the high drying rate. But when using them, you must follow all necessary precautions. These products are toxic, therefore their application should be carried out only in a respirator, special clothing and gloves.

Their application does not provide a preliminary primer, but it is imperative to treat the surface from areas of corrosion damage. Such coloring materials are resistant to gasoline, salts and oils. The most popular are gray, black and silver, although there are people who want to paint their design in red or brown.

to contents ↑The process of painting the barbecue

Application of organosilicon composition

Before painting, make sure that the surface is perfectly dry. Remove dust, debris, oils, or other contaminants from it. In order to remove possible areas of rust, scale, corrosion, or an old coating, you can use a drill with a nozzle, or ordinary sandpaper.

Then the area to be painted is recommended to be degreased with any solvent available. Immediately before starting work, the contents must be mixed well so that the precipitate and all kinds of clots completely dissolve. To assess the viscosity (density), it is recommended to apply a small amount of coating, and if necessary, dilute it with any available solvent. It is applied by roller, brush, by spraying or by dipping into a large container, depending on the size, useful life and design of the barbecue.

The procedure will be effective provided that the ambient temperature is not lower than -20 ° C, and not higher than + 40 ° C. It is recommended to apply the coloring composition crosswise - crosswise up to 2, sometimes 3 times, with intermediate drying from half an hour to two hours.

to contents ↑Applying acrylic paint

Particularly popular when painting the barbecue are acrylic products in aerosol cans. Due to their unique composition, these dye preparations are very durable, highly effective, dry quickly, have many positive, including anti-corrosion properties.

When working with them, all safety precautions must be strictly observed, do not spray them near an open flame, etc.Since they relate to flammable compositions, they must be used carefully and strictly observe fire precautions. Aerosol products are very toxic, for this reason you can only work with them by wearing special clothes, gloves, and a respirator to protect your respiratory system.

The application of this type of coating does not provide a preliminary primer, only it is imperative to remove areas of the barbecue surface damaged by corrosion. The color palette is quite diverse, but the most popular colors are black and silver.

Before starting work, the painted surface should be cleaned of dust, debris, and other contaminants, and be sure to degrease. Ensure the mixing of the paint by vigorously shaking the can for one minute. Effective staining will be achieved by spraying at a distance of up to 20 cm, and applying the composition in 2-3 layers.

The intermediate drying time should be about two hours.

Burnishing (chemical oxidation) is considered an alternative to the traditional dyeing of such products. This innovative technology is not very convenient for home use, and is only possible in the case of disassembled construction.

Heat-resistant coating, like many modern paints and varnishes, does not differ in low price. But the costs of its acquisition will justify itself over time, and will ensure a long and effective life of the attribute of the festive atmosphere - your wonderful brazier.

Modern heat-resistant paints that prevent the destruction of the material, and resistant to high temperatures - an effective solution to your problem.