Sometimes in the process of work or in everyday life it is necessary to fasten metal parts together. It is not always convenient to solve the problem by welding or screw connection. Then an equally durable tool comes into play - metal glue.

- Adhesive Characteristics

- Scope of application

- Properties of heat resistant base

- Adhesive Requirements

- Types of glue for metal products

- How to connect metal surfaces

- Static hard bonding of metals

- Deformation bonding of metals

- Epoxy resin

- Bonding materials with different linear expansion coefficients

- Bonding of metals subject to moisture

- The advantages of metal glue in achieving production goals

This special adhesive, available in various forms, firmly and reliably connect metal with metal and other materials (wood, plastic, leather, glass, aluminum, paper). You can even glue surfaces that seem incompatible.

to contents ↑Adhesive Characteristics

Glue for joining metals has its own technical characteristics that differ from different manufacturers. When choosing a specific adhesive composition, it is necessary to pay attention to its following properties:

- drying time and conditions - as a rule, it depends on the place where gluing is performed and the specifics of the work itself;

- the maximum temperature at which the beneficial properties of the adhesive are preserved - you should choose a composition that can withstand the conditions of use of the assembly, or its future processing;

- application method - some adhesives are recommended for spot processing, others - for full coverage of the joints of the parts;

- bonding technology;

- consistency - these can be tubes with a composition and hardener, as well as plastic sticks. The second is convenient because you do not need to knead: being in any place, you cut off a piece, knead it and use it;

- materials with which bonding is possible - universality here is a blurry and unreliable concept; it is better to choose narrowly targeted glue to solve a specific problem. For example, to connect plastic and metal.

Scope of application

Metal glue is broadly applicable in many areas of life. In industry and in everyday life, breakdowns often occur.

The child’s toy broke - we are looking for an opportunity to fix it. It is necessary to repair the car, the exhaust pipe, to repair any damage - there is also a need to reliably connect metal surfaces to each other. In the aviation, civil engineering and chemical industries, bonding of metal parts is also widespread.

to contents ↑However, the compositions may vary for a narrow purpose, and be universal. For example, professional heat-resistant glue is often used to repair plumbing, to eliminate cracks in metal, when building fireplaces and stoves, when installing a warm floor, and for many other tasks.

Properties of heat resistant base

If during operation metal components are exposed to elevated temperatures, their integrity is destroyed over time, and the service life is reduced.

Heat-resistant composition of the type "300" based on epoxy resin will be a worthy alternative to welding.

Even the high temperature mode of operation of the device will not damage the connection of the components. The lower limit of stability of the heat-resistant composition is 300 degrees Celsius. In addition, it is waterproof, heat-conducting and environmentally friendly.

to contents ↑Adhesive Requirements

High-quality glue for metal after its application must fulfill several conditions:

- the most durable connection that allows you to use parts without risk;

- preservation of properties over time;

- resistance to temperature extremes;

- chemical neutrality, protection of the bonding place from corrosion;

- water resistance;

- minimal shrinkage after curing;

- lack of pungent odors;

- environmental friendliness.

Types of glue for metal products

Modern adhesives for fastening metal surfaces according to the extent of their application are divided into two main categories.

Two-component adhesives are compositions that can connect parts from different materials (wood, concrete, metal). Widely used both in everyday life, and in installation, repair work. Grasping, such glue becomes quite plastic. However, this does not prevent him from holding the glued parts tightly.

One-component adhesives have a narrow focus. Such a composition is recommended to be used at a temperature not lower than +5 degrees Celsius. For industrial applications, it is available in aluminum tubes, which allow it to retain its beneficial properties for longer.

Glues of fast hardening and, accordingly, slow are also emitted.

Such adhesives for metals are considered effective:

- epoxy adhesive ("Moment", Bf-2) - it includes resin and fillers that accelerate curing;

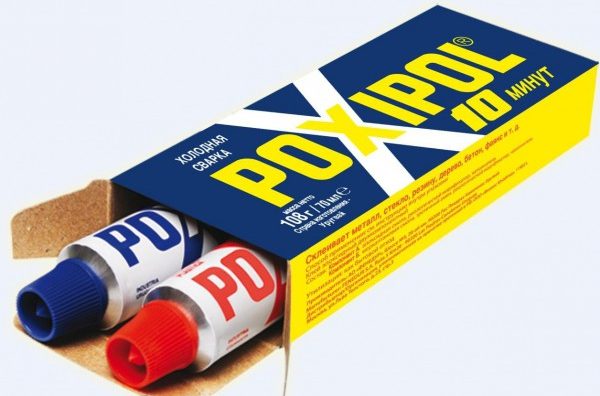

- cold welding (Poxipol) - contains one or two components, deforms the welding mass, introducing it into the surfaces to be glued - so it adheres them as tightly as possible;

- double-sided tape - adhesive tape on a polypropylene or foam base.

How to connect metal surfaces

Before proceeding with gluing, it is necessary to properly prepare the surfaces, remove signs of corrosion and traces of contamination from the parts. Do not use solvents or gasoline, so as not to leave an unnecessary layer of additives.

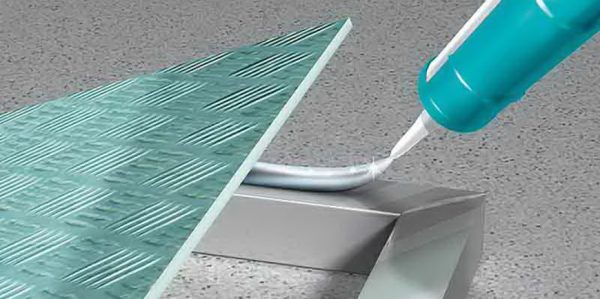

Then mix the cold welding components thoroughly. Next, the finished mass must be applied to the surfaces that need to be glued. The next step is to press metal parts together or put them under the press.

to contents ↑Improving the quality of gluing will help surface treatment with a special primer that preliminarily degreases them and improves adhesion.

Static hard bonding of metals

Adhesives for this type of bonding are compositions with increased mechanical strength. They are used when working with racks, signboards, furniture, display cases - with structures that do not have significant loads.

Deformation bonding of metals

This type of bonding, on the contrary, is suitable for dynamic objects (elevators, machine tools, fans, cabs and bodies). For some static objects, they can also be used if they are subjected to temperature deformation.

Epoxy resin

Many formulations are based on epoxy. It has high adhesion to various materials, even to metal, plastic and glass. Under the influence of hardeners, the epoxy resin polymerizes and hardens.In this state, it is harmless to humans and animals. Epoxy that has not hardened is a powerful poison that can cause serious harm.

When gluing metals with epoxy resin, it is possible to obtain both an elastic deformation and a static rigid seam.

to contents ↑Bonding materials with different linear expansion coefficients

When heated or cooled, the adhesive bonding of these materials experiences severe load deformation. It is recommended to glue them with a polyurethane mixture. There is no noticeable difference between deformation bonding and joining materials with different expansion coefficients. The only difference is that in the first case, the adhesive joint is required to withstand high temperatures.

to contents ↑Bonding of metals subject to moisture

If metals are exposed to moisture for a long time, they are oxidized and corrosion appears on them. Its occurrence is promoted by the fact that the glue absorbs moisture, which has been near the glue joint for a long time.

To avoid this, carry out additional sealing of the adhesive joints, for example, with a layer of waterproof paint.

The advantages of metal glue in achieving production goals

As for production, now gluing products is a worthy alternative to welding and other types of joining of metal parts. Some of their advantages, from a professional point of view:

- at deformation load, they exceed the point contact in terms of design reliability;

- adhesives significantly reduce or eliminate corrosion problems;

- by gluing metal structures, we make them more resistant to vibrations and shocks;

- the technology of point or plane bonding of metal parts saves the means of production, making production processes cheaper.

When gluing metal parts, you need to take into account the features of the future assembly, correctly select the glue and carefully prepare the surfaces. Thus, it is possible to glue even what cannot be welded.