Often during the repair process it is necessary to glue dissimilar materials, for example, plastic and metal products, rubber and iron parts. For this purpose, special glue for rubber and metal is perfect — a type of superglue that has excellent performance characteristics.

- Adhesive properties

- Types of Rubber Adhesive

- Glue selection

- The best brands for bonding

- Instructions for use of the composition

Adhesive properties

Rubber adhesives are rubber-based products dissolved in special substances. After hardening, they remain elastic, therefore, they are suitable for bonding materials of unequal structure. Also in the composition may be other components that improve the properties of the adhesive:

- polymer resins;

- crosslinking agents;

- vulcanizing additives;

- plasticizers, etc.

The material is used in industry and for domestic purposes, can be used as a high-strength sealant. High-quality glue will quickly fill the smallest holes and voids, cracks and seams, and the product will be fastened tightly. Distinctive properties of glue for rubber:

- high adhesion;

- the strength of the adhesive joint, the absence of damage over a long period of operation;

- resistance to temperature (usually in the range of -40 ... + 100 degrees), aggressive substances, chemistry;

- joint flexibility;

- lack of an unpleasant smell;

- transparency.

to contents ↑Some formulations are heat resistant and can withstand even more heat. Any glue for rubber is waterproof, it does not allow moisture to penetrate into the glued area.

Types of Rubber Adhesive

All means for bonding rubber can be divided, depending on the proportion of solids (in%) into two groups:

- group A - 6-8%, the compounds are more elastic;

- group B - 8-12%, products are less elastic after drying.

In addition to rubber, a number of synthetic components are introduced into most modern adhesives, which seriously improve the properties of the material. The composition of adhesives is also divided into several types, their basis may be as follows:

- Natural rubber. It is better not to use a tool to connect complex parts and metal products - the adhesion level is average, as well as resistance to temperature extremes, natural factors.

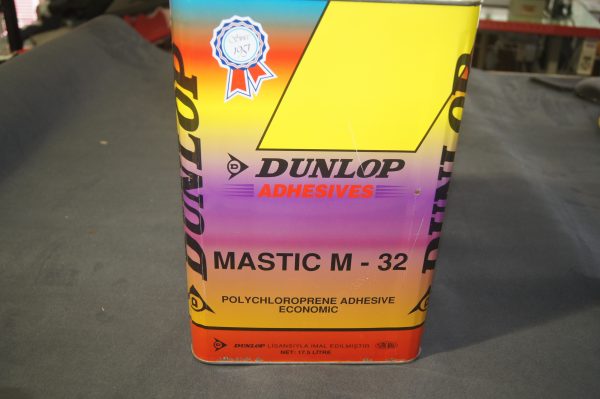

- Chloroprene In such adhesives, among other things, metal oxides are present, so they are excellent for bonding rubber to metal surfaces and for performing other complex compounds.

- Nitrile butadiene rubber. As a vulcanizing component, sulfur acts in such products; tiurams are also introduced into the composition. The glue is super-water resistant, has good adhesion to rubber and metal.

- Organosilicon components. Curing occurs with the participation of tetrabutoxylan. The tool is only suitable for gluing rubber to rubber, for example, for repairing tires in a car.

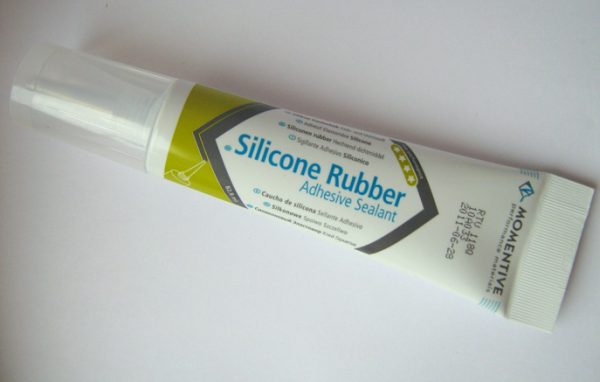

By type of container, all adhesives are divided into household and industrial. The former are available in small tubes and bottles, the latter in cans, buckets, drums, and their application to glued surfaces is usually carried out using special equipment.

to contents ↑Glue selection

What glue is better to use, what are the selection criteria? If you need to firmly glue metal with rubber, you should look for a tool with enhanced adhesion, which gives a reliable seam, while being elastic. It is also important to consider a number of factors:

- humidity and temperature in the rooms where gluing will be performed, and then the operation of the product;

- load on glued surfaces;

- the need for high aesthetic properties of the finished product;

- the degree of chemical aggressiveness of the adhesive, taking into account the type of metal.

When buying, it is important to clarify in the instructions or on the packaging that the manufacturer guarantees the suitability of the composition for rubber and metals, alloys. Universal tools are far from always suitable for such a complex junction, as well as for joining other dissimilar materials. After drying, the seam should not exfoliate from the base, must be heat-resistant and not change the strength under the influence of low temperatures.

For cars, it is often advised to buy products such as "liquid rubber". They can perfectly glue rubber surfaces, as if becoming part of them, therefore they are outwardly invisible. The water resistance of the glue is another important point when choosing, this property is required by almost every user, especially the car owner. If necessary, you can buy glue that allows you to operate parts even under water.

to contents ↑When joining rubber and metal, it is important to eliminate corrosion, because there is always a note on the quality of the composition on the quality glue. A separate type of adhesives is considered to be means for silicone rubber, which is soft, supple. On a tube of such glue there is an inscription "for elastic materials".

The best brands for bonding

How to stick metal or other complex materials to rubber? For this purpose, it is worth purchasing only proven compounds:

- 88CA. Resin glue on organic solvents, contains phenol-formaldehyde resin, nefras, ethyl acetate. It perfectly fits both painted material and concrete, glass, wood, and is suitable for dissimilar substrates. The composition is waterproof, does not exfoliate from the action of moisture, after drying does not give toxic fumes. It does not interact with metal, therefore it does not provoke corrosion.

- U425-3. The properties are similar to the tool described above, since it has a similar composition. It is used for bonding with subsequent vulcanization, if necessary.

- 4NB-UV. The glue is oil-resistant, water-resistant, but can withstand heating only up to +60 degrees, while it is frost-resistant - it is not damaged from freezing to -40 degrees. They can stick rubber, rubber-fabric materials, metal. Such a composition forms a very elastic seam, has a residual stickiness. It is ideal for the repair of various rubber products, boats, chemical protection suits.

- Radical. This glue can even serve in sea water, it does not break down due to the action of salts and alkalis, therefore it is popular among fishermen (it is used to repair any boats).

- The moment is rubber. Suitable for hard and foamed rubber, provides high strength, resistance to water and oils, elasticity of the adhesive joint.

Also, for complex surfaces, adhesives such as Super-NN, Rogneda, Loktayt Super Fast are often used. Some users, in order to save, make rubber adhesives on their own. To do this, soft rubber is crushed, filled with aviation gasoline to completely cover the mass. After 2-3 days, the liquid is filtered. After standing in the heat for another couple of days, the glue will be ready.

to contents ↑Instructions for use of the composition

First, the foundation needs to be prepared. To do this, it is cleaned of all types of pollution. There can be traces of corrosion on the metal, they are cleaned with sandpaper, a grinder, a file, this will also increase the level of adhesion. Rubber is not processed by grinding, since there is a risk of damage to the material. Immediately before work, both parts are degreased with gasoline, acetone, and alcohol.

Most adhesives are applied in the usual, cold manner, but there are those that require the use of hot bonding technology.In this case, the surfaces are heated, like the glue itself, to a temperature of + 70 ... + 160 degrees, then gluing is performed. The procedure in ordinary cases is as follows:

- grease both parts with glue, applying a thin layer, the remains of which will not come out (about 2 mm), for convenience, you can use a brush or spatula;

- squeeze the products, fix until completely glued (usually no more than 30 minutes), using a vice, a heavy object or holding hands;

- the adhesive joint interfering with operation can be cut off, sanded with sandpaper;

- glue stains must be removed before it hardens with a knife, spatula, otherwise you will have to buy products such as "Antikley";

- it is better to put the product into operation no earlier than a day after gluing.

Some formulations become very thick during long-term storage, so when buying, you must immediately evaluate the shelf life - it should be sufficient. It is not difficult to glue rubber and metal with a high-quality tool; this can be done at home.