Cork wallpapers, panels and other coatings made of this material have come into use recently, although cork itself has been used by mankind for many centuries. If earlier it was used only for the manufacture of floats, covers or shoes, now it is increasingly used by designers to equip premises.

- Types and characteristics of cork materials

- Key Features and Capability of Cork Adhesive

- Acrylic solutions

- Water based solutions

- Solvent mixtures

- Popular brands

- "Moment Cork"

- Bostik quelyd kork

- Decol vern

- Wakol d 3540

- Cork house

- How to glue cork panels to the wall: instructions

- Material preparation

- Foundation preparation

- Ground application - what is required

- Wall marking

- Gluing the cork to the wall - getting started

- Cork Attachment Feature

- Mounting technology

Beauty, environmental friendliness, durability - these are the main advantages of the material, increasing its popularity from year to year. For wall mounting, high-quality cork glue is required, as well as a clear knowledge of its application technology.

to contents ↑Types and characteristics of cork materials

Now, various types of coatings from cork to walls and floors are being sold in construction stores. As for wall materials, they come in two types: wallpaper and panels. Wallpaper can have a paper base or be a roll cork canvas.

The former play a decorative role; from above they are coated with a varnish or wax composition. Due to their light weight, they can stick not only to walls, but also to the ceiling. The effect of heat and sound insulation due to the small thickness should not be expected from them. Some wallpaper needs to be planted on the adhesive, from others it is enough to simply tear off the inner substrate and fix them as a self-adhesive film.

A cork roll is also used as wallpaper, but costs an order of magnitude more. It is thick, durable, sold in rolls that are not subject to bending. This material is 100% natural, sometimes it is even sold in its raw form, and after gluing it requires additional decorative finishes. Most often, this canvas is used for pasting the kitchen, hallway.

Other cork finishing materials:

- Panels. Top coated with varnish, wax, ideal for wet rooms.

- Plates. They have a different shape than the panels (usually wider and shorter), serve as insulating material from noise, cold.

- Tile. It happens single-layer, two-layer. The first option is simple tiles from one layer of material. The second type of tile has a brightly colored lower and veneered upper layers. Colored fragments in a two-layer tile are slightly translucent.

For the floor, a cork substrate is used, which is usually laid under the parquet, laminate. It reduces heat loss, reduces noise, neutralizes base defects. Such substrates can also be glued to the walls under any finishing material in order to warm the room, sound insulation, improve the adhesion of wallpaper to the surface.

to contents ↑Key Features and Features of Cork Adhesive

Cork is a rather expensive material that serves for many years, so glue for it also needs to be selected according to the criteria of quality and performance without complaints. Most adhesives work at temperatures from + 15 ... + 20 degrees and humidity up to 70%. The compositions should have a short time before the initial setting so that they do not have to press the cork panel for a long time. High-quality glue must possess the following properties:

- resistance to moisture;

- high adhesion to cork and base material;

- resistance to temperature extremes;

- lack of a negative reaction to contact with paint, varnish, wax, and other finishing materials.

The following are the main types of formulations that may be suitable for bonding cork materials.

to contents ↑Acrylic solutions

Despite the fact that acrylic adhesive is reliable, environmentally friendly, odorless, and also guarantees high quality adhesion of materials to each other, professionals do not recommend using it for cork. The composition will eventually destroy the surface of the cork coating, worsen its strength properties.

to contents ↑Water based solutions

The cost of such adhesives is quite high, because most of them have foreign production. But the reliability is at a high level, the consumption is small, since the adhesive is applied to the wall or cork material with a thin layer. As the liquid evaporates and the final polymerization, the joint will gain serious strength. Compositions based on water are odorless and harmless, because they consist of natural components.

to contents ↑Solvent mixtures

Such adhesives are characterized by an even higher level of adhesion, firmly adhere to cork, wood, and sometimes they are universal and suitable for most building materials. They are seized almost immediately, you will not have to wait a long time for gluing the panel to the wall.

to contents ↑The disadvantage of such adhesives is the unpleasant odor that comes from organic solvents introduced into the composition. Glues are toxic (before solidification), they will have to be handled with strict observance of safety measures. Do not work near fire sources - all solvents are flammable!

Popular brands

Among the adhesive products that can be used to connect cork products, those belonging to foreign manufacturers are more common. You can not find them in all stores, and the range of such adhesives is small.

"Moment Cork"

This contact adhesive is a special compound for joining various products from cork, as well as for combined bonding of cork and other materials. It perfectly holds the finish on wood, metal. The tool is frost-resistant, cost-effective and cost-effective, durability of the adhesive joint after drying. “Moment Cork” is resistant to weak acids and alkalis. The most popular areas of application of glue:

- laying wall, floor coverings, moldings from cork, roll and sheet substrate;

- bonding cork with leather, rubber, wood, various metals and alloys, hard PVC, felt.

to contents ↑Do not use glue for joining polyethylene, polypropylene, styrofoam, as well as plasticized PVC. The product does not contain toxins, harmful solvents. When hit on various surfaces, you just need to wait for drying, roll it into a ball and remove.

Bostik quelyd kork

This glue is also used for cork in rolls and in the form of tiles. It is intended for thin coatings (up to 5 mm thick) when gluing on the base of cement, wood, gypsum only indoors. The adhesive is not suitable for work in rooms with high humidity - kitchens, bathrooms.

The main characteristics of the composition:

- provides high strength seam, which is not affected by mechanical damaging factors;

- makes it possible to adjust the position of the sheet, tile within a few minutes;

- has good adhesion to various base materials;

- has a color close to the shade of the cork;

- does not contain solvents, is not flammable;

- frost resistant.

This glue is made on the basis of vinyl polymers. You can work with it at temperatures from +10 degrees, humidity up to 60%. The time to initial solidification is 10 minutes.

to contents ↑Decol vern

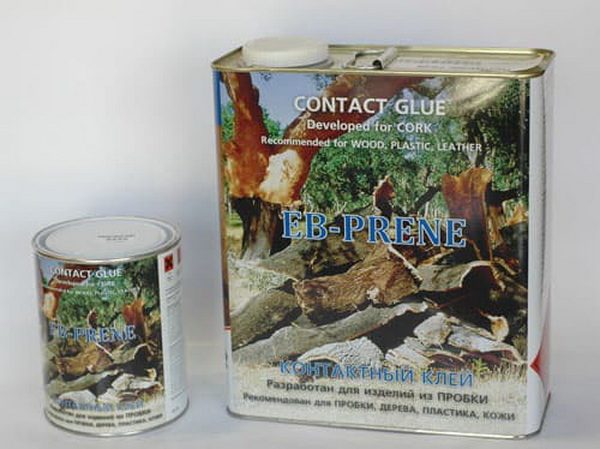

Contact adhesive of this brand is made on a polychloroprene basis, includes synthetic resins. It is ideal for all cork coverings, including floor and technical cork, and is also recommended by most manufacturers of cork wallpapers. The product emits an unpleasant odor during operation, but gradually disappears as it dries.

Decol Vern glue is toxic, you need to work with it only with the use of personal protective equipment and in a ventilated area. The composition is flammable, flammable. The glue quickly sets, making it possible to adjust the position of the parts for a minimum time. The requirements to ensure good adhesion are as follows:

- humidity in the room - less than 65%;

- air temperature - from 0 degrees;

- humidity of the base is 2.5-3%.

Wakol d 3540

Glue of this brand is produced in Germany, belongs to water-dispersion compounds, has a latex-acrylic base. It is used for gluing corks of any type up to 6 mm thick on concrete, brick, wood substrates, including porous ones. The product is intended exclusively for internal use, as it does not have frost resistance. The composition is environmentally friendly, not harmful to humans, as it does not contain solvents.

In the application of Wakol D 3540 glue there are some features:

- the base must be dry, porous, strong, without falling pieces and residues of organic compounds;

- concrete and cement-sand coatings should first be primed with a primer of the same brand;

- before applying the glue should stand at room temperature, it must also be thoroughly mixed;

- on absorbent substrates, the drying time of the layer is 30-45 minutes, on non-absorbent ones - 60-90;

- working time with glue is 2-3 hours;

- glue consumption is 250 g / sq. m;

- cork laying can begin when the adhesive layer changes color from white to transparent;

- on complex bases, it is advisable to apply glue to the coating itself, leave for a day, and then lay in the usual way;

- you can walk on cork material immediately after gluing it, and applying varnish, oil is permissible only after a day;

- it is possible to work with glue at a temperature from +18 degrees, humidity to 70%.

Before working with the composition, you need to make sure that the base meets the following requirements: humidity - less than 4%, temperature - more than +15 degrees.

to contents ↑Cork house

Contact adhesive for cork coatings Cork House is intended for gluing technical cork up to 10 mm thick to a variety of materials - concrete, fiberboard, chipboard, wood, brick, etc. It is important to apply the product on both bases - with the help of a velor roller on the cork, with a notched trowel - on the wall, floor. Apply the coating 20 minutes after applying the adhesive. Correctly and carefully pressing the cork is important immediately, tearing and re-applying are not allowed. Full drying occurs after 2 days.

to contents ↑How to glue cork panels to the wall: instructions

Using cork, you can finish the floor in the room, and there is no need to remove the previous coating (laminate, linoleum). “Floating” tile floors from corks are collected quite quickly, and when moving, they can be easily folded and taken with you. With proper bonding, the coating will soften the sounds of walking and falling objects, even withstand heavy furniture.

to contents ↑The walls and ceiling are decorated with cork, and for the latter, the same wallpaper that is purchased for wall repairs is suitable. It is possible to cover surfaces in a room with a continuous method or fragmentary, as the fantasy tells. Among other things, it is possible to finish furniture with a stopper, for example, to replace damaged parts.

Material preparation

Before installation, cork sheets or rolls must be kept indoors for at least 24 hours to help the material “adapt”. Among other things, the roll cork is unwound and hung up for some stretching and adoption of the working form. Cutting is easiest to do with a sharp construction knife that has interchangeable blades. After they cut holes for sockets, switches.

to contents ↑Foundation preparation

Walls before gluing cork wallpaper are thoroughly cleaned, leveled, dried. Be sure to remove the areas with mold that managed to damage the previous coating. The crumbling sections are cleaned, putty again, otherwise the cork will lie unevenly. Cork materials are poorly compatible with gypsum, so gypsum plaster should not be used.

to contents ↑The maximum height difference is determined by the floor, if it is significant, you will first have to carry out a concrete screed. At the end of the preparatory phase, the walls are primed 1-2 times (there should also be no gypsum in the primer). For wood processing, primers with the fire protection function are additionally used. The surface is dried to an acceptable level of humidity, for which, if necessary, use a heater, heat gun.

Ground application - what is required

Many skip the priming stage, although in the case of cork, it will greatly facilitate further work. The composition is partially absorbed into the upper layers of the base, strengthening the material and increasing its strength. After priming, adhesion with glue increases, so the reliability of the glue line will be significant. In addition, when applying the soil, the remnants of dust are eliminated, and the glue will lay down more evenly, will not roll and stray into lumps. If the base is complex, highly absorbent, it is better to apply the soil twice.

to contents ↑Wall marking

Directly before work, the walls are marked, especially if fragmentary gluing is planned. Before attaching the tiles, you will have to draw a grid, and when gluing the walls with canvases, only signal lines can be applied. If this is not done, there is a risk of skewing the products, which is especially common when processing large areas. The easiest way to do this is with the laser level.

to contents ↑Gluing the cork to the wall - getting started

Usually begin to finish the walls, floor from the window or from the corner. In general, this does not play a big role, the master will be able to independently choose a site for the start of repair. Then you should remove all sockets, switches, and close the technological holes with cardboard pieces cut to the size of the holes.

to contents ↑

Cork Attachment Feature

Cork tiles are installed according to the principle of brickwork - they shift the next row by ½ from each lower element. Wallpaper glued butt, leaving no gaps and no overlapping.

Mounting technology

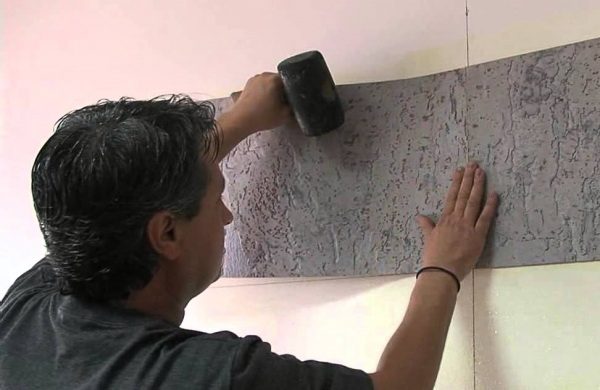

The adhesive is applied only to the cork or to both surfaces - the wall, floor and finishing material. The thickness of the layer is observed according to the instructions, but it should not be more than 2-3 mm. It is most convenient to apply glue with a roller, a notched trowel or a comb (for thick compositions). Do not immediately glue too much material with glue - the composition should not seize until it is applied to its intended place. Be sure to observe the time indicated by the manufacturer for adjusting the position of the cork and fix it until the end of this period.

After attaching the element or strip to the wall, it is carefully pressed, starting from the bottom edge. In the case of wallpaper, the edges are additionally smeared with glue with a brush. After rolling the cork with a rubber roller. As the work is completed, wait until it completely dries, then cover the seams and the material itself with a protective compound, varnish. It is impossible to neglect this item, otherwise the material will serve less. Best suited products with wax in the composition.

If the adhesive contains a solvent, work only in a respirator. When the product gets on the front side of the cork, it is difficult to remove it, it is better to first protect the edges of the elements with masking tape. The adhering drops are heated with a hairdryer, then blotted with a napkin. Heavily contaminated areas are best replaced with new ones.Cork is an expensive material, you need to work with it with care, so as not to overpay and immediately get an excellent result!