Penoplex is an improved type of polystyrene with polystyrene based. In fact, penoplex is the trade name for extruded polystyrene foam. The characteristics of this material allow its use for thermal insulation - insulation of the room. It is used for interior work, exterior decoration.

- Types of adhesives

- Polyurethane-based formulations

- Penoplex Fastfix adhesive foam

- Mineral adhesives

- Polymer adhesives

- Waterproofing Compounds

- Instructions for sticking foam

- Mounting technology

- Glue consumption

- Filling of foam

- Exterior foam protection

- Bonding stone and tile on foam

- Questions and answers

- Choosing glue and what is better not to use

The choice of expanded polystyrene by professionals is due to its excellent properties, favorable price. The material is glued to the walls with glue. It is important to choose the right adhesive for foam and apply strictly according to the instructions.

to contents ↑Types of adhesives

What composition to stick foam to the surface of the wall, ceiling? There are many options, but you need to choose a remedy carefully. Such glue will hold not only the material itself, but also the entire insulation design. If the quality of the glue is low, it will not retain thermal insulation.

There are several types of adhesives, depending on the composition:

- mineral;

- polyurethane;

- polymeric;

- waterproofing.

The first type is used to work with a dry surface, because with high humidity, mineral components harden immediately. It is better to carefully study the advice of the glue manufacturer before buying. This will allow you to choose the right composition. Caustic, aggressive components should be absent in it, because penoplex is a whimsical material, its structure is easy to destroy.

to contents ↑Polyurethane-based formulations

For the installation of foam, such tools are often used. Most are sold in cylinders, so it’s convenient and easy to use even for a beginner. Means are ready for use, they do not need to be kneaded, economical consumption. The most popular line-up is Insta-Stick (Insta-Stik). It is sold in bottles of 750 ml, the consumption for gluing is 12-15 square meters. m, setting time - 20 minutes. Breakaway force - up to 400 KPA. The disadvantage is frost resistance - you can not glue foam on walls at temperatures below 0 degrees.

Another well-known glue is Titanium Styro-753. Its consumption is about the same (about 14 sq. M). The product has a high pull-out force (600 KPA), and the setting time is even less (15 minutes). Penosil Fix & Go Montage is frost-resistant, it is operated at -65 ... + 130 degrees. Using the described tools, it is easy to connect the sheets of foam with each other, stick on wood, attach to a brick wall, to concrete.

to contents ↑Penoplex Fastfix adhesive foam

This foam with adhesive properties is widely used for fixing thermal insulation from extruded polystyrene foam to all kinds of substrates - ceramic tiles, concrete ceilings, floors and walls, drywall, aerated concrete, and brick. Penoplex Fastfix adhesive foam (Penoplex Fastfix) is made in 750 ml cylinders, the product itself is light blue.

If necessary, the adhesive will provide adhesion to most building materials. Among them are plaster, stone, wood, expanded clay blocks, metal, cork, cellulose. If the material had to be foil, this product is incompatible with it.Foam is not suitable for polyethylene, silicone, teflon. Here are the main characteristics of the material:

- drying - 10-12 minutes;

- full hardening - 24 hours;

- the possibility of cutting - within 30-40 minutes.

The tool is used for outdoor work, and for indoor thermal insulation in the room, suitable for warming loggias, balconies.

to contents ↑Mineral adhesives

Mineral-based adhesives in the composition have cement, gypsum, alabaster. They harden very quickly, they must be applied immediately. Glues are kneaded in small portions. Outside the premises, only cementitious compounds are usually used; products with gypsum components are suitable for indoor use. The setting time is long, up to 1.5-4 hours, so there is an opportunity to fix the flaws.

The disadvantage of the compositions is that the base must first be well primed, and wait for complete drying, otherwise the connection will not be durable. Also a minus is the need for dilution, to obtain a high-quality homogeneous mixture, you need a construction mixer.

The most popular brands of mineral adhesives:

- Ceresit CT 83 - used directly for bonding foam, suitable for all substrates, peel force - 500 KPA, high frost resistance class.

- “Atlas Stopter K-20” - has an increased pull-out force (600 KPA), is viable for 4 hours, consumption is 4.4 kg / sq. m, in the composition there are special reinforcing fibers.

Means of this type are sold in bags of 5-25 kg, cost about 300-500 rubles. for 25 kg. If the bag indicates frost resistance class F50, the product is suitable for interior use. Class F100 means that the boards can be glued outdoors.

to contents ↑Polymer adhesives

Is it possible to fix penoplex with adhesives in small cans? Typically, polymer adhesives are sold in such containers; they are ready for use on any surface. Bonding with this method is practiced if it is necessary to fix the foam to metal. For beginners, it is better not to buy such compositions - they catch instantly, it will be impossible to fix defects.

A good tool for plates - glue "Moment". It is resistant to humidity, temperature extremes, produced in convenient packaging at 0.25-1 liters. Consumption is low, even a small pack is enough for 4-5 square meters. m. Another tool - "Emfikol 225", its technical characteristics are similar. After use, the room should be well ventilated for 2-3 days, but in the air it is ideal to work with it.

to contents ↑Waterproofing Compounds

This group of materials that will stick penoplex includes bitumen adhesives, acrylic, rubber, they are made in the form of mastics. You cannot buy simple ones, they corrode the material, as well as waterproofing agents with oil products. Better than can be glued penopleks, this tool "Bitumast XPS." Mastic does not include solvents, sets in 2 days, has a high pull-out force - 500 KPA.

Acrylic adhesives can easily attach penoplex to wood, concrete, brick, connect penoplex with penoplex, stick penofol with penoplex. They are suitable for indoor and outdoor use, have a very low consumption. Bituminous mastics have the most pronounced waterproofing properties, are resistant to low temperatures.

to contents ↑Instructions for sticking foam

When you choose what to attach the material to, you can proceed directly to work. It is important to properly prepare the surface of the base, you can do it yourself. It should be cleaned of debris, dirt, dry. If the manufacturer recommends, the surface must be primed first. Next, you need to cut the necessary pieces of the main material. How to cut penoplex? For this purpose, a clerical knife or jigsaw is used.

to contents ↑Mounting technology

After drawing up the installation plan, you can start gluing the product to the floor, walls or ceiling. Mineral wool is often used for penoplex.

There are several ways to glue on glue:

- point;

- solid;

- boundary.

to contents ↑The point method is more often used, while liquid glue is applied with a spatula 100-200 mm wide. After this, wait a certain time and press the material to the surface.After complete drying, the joints are sealed with foam or the same glue. The second option is much more expensive.

Glue consumption

All useful information for the user, including material consumption, is always indicated on the packaging. The usual indicator is 3.5-5.5 kg / one standard layer of material (for mineral mixtures). Glue in cylinders is more economical, less is consumed (from 10 sq. M per cylinder).

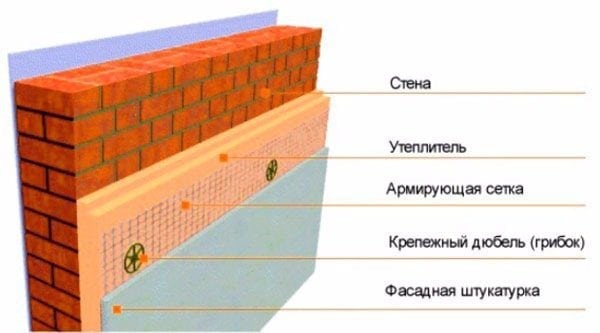

Filling of foam

After the glue has completely dried, the foam can be additionally fixed with dowels, this is more reliable. Next, puttying with finishing materials is performed. Putty should be smoothly, in layers, smooth the putty smoothly. After the first layer, a mesh of metal, plastic, reinforcing is attached. The thickness of the first layer is up to 1 cm, the second is a little less. 2-3 layers are performed as desired, with the third layer usually being sprayed and up to 5 mm thick.

to contents ↑Exterior foam protection

For external protection, special glue is used. Which is used in this case? Suitable tool with high adhesion to the surface, you can choose the brand "Ceresit", "Master", "Polimin." Some professionals prefer to use "Giprok" - a insulation similar to drywall.

Bonding stone and tile on foam

After the final stage of work, you need to think about the finish. Most often it is recommended to stick ceramic tiles, porcelain tiles or artificial stone. This is done with tiled glue with frost-resistant qualities, with its help you can easily and quickly finish floors, walls. Be sure to apply several layers of plaster, preferably “Ceresit ST 85” with a reinforcing mesh. Indoors, it is recommended to make a cement screed on the floor, and then create a decorative coating.

to contents ↑Questions and answers

There are a number of issues that concern users regarding the use of foam.

How to glue foam with foam?

There is no difference between how to glue two sections of the foam and this material with other surfaces. But experienced builders argue that when bonding plates to each other, it is better to use a continuous method of applying glue, while you can do without a primer. In this case, the dowel-nails will not be required, and the glue will suit any of the above.

Is it possible to glue material on a mounting foam?

You can stick penoplex on the foam, the adhesion will be strong. On the floor, this type of work is carried out on a bulk concrete screed. But gluing on a mounting foam is very expensive. It also has the ability to expand, you have to constantly press it until the process is completed.

Is it possible to glue foam on liquid nails?

Liquid nails can be used, it’s not very convenient. Before putting the plate in place, it should take up to 7 minutes, otherwise the glue will not seize. In addition, the price of work will increase significantly.

Does air temperature matter?

It depends on the type of adhesive. Some lose their properties at low temperatures. Others allow work in the cold. All data must be clarified in the instructions.

to contents ↑Choosing glue and what is better not to use

Before buying, you need to consider the following points:

- acceptable price;

- suitability for use indoors or outdoors;

- adhesion strength;

- consumption;

- harmlessness (for interior decoration).

Typically, for internal work, they buy any polyurethane, polymer adhesives. It is forbidden to use waterproofing materials indoors, they can be harmful to health. Outside the house, cement-based mineral mixtures are often used. For outdoor work - balconies and socles, acrylic mixes are ideal.

You can not apply for penoplex compounds with benzene, toluene, acetone, formalin, xylene. Kerosene and gasoline, coal tar and polyesters, formaldehyde will also spoil the material.Otherwise, you can easily glue the material with your own hands without extra costs.