Expanded polystyrene, or ordinary polystyrene, is a material widely used in construction and repair. It has an environmentally friendly composition, is economical in price and easy to use. The life of the foam insulation is directly affected by the choice of means for fixing it. Adhesive for foam should securely fasten the material and serve for many years.

- Glue Selection Requirements

- Types and manufacturers of adhesives

- Dry mixes

- Polyurethane adhesive foam

- PVA

- Polyurethane foam

- Liquid Nails

- Joining foam to different surfaces

- Concrete

- Metal

- Tree

- Other surfaces

Glue Selection Requirements

You can glue polystyrene foam on the walls, ceiling or other surfaces for insulation with your own hands - the process is simple. High-quality adhesive is required to meet a number of requirements. First of all, it should contain no harmful, destructive foam components:

- ketone-based solvents, including acetone;

- nitrogen compounds - nitromethane, nitrobenzene and others;

- chlorine derivatives;

- petrochemicals - gasoline, white spirit, kerosene;

- alcohols and esters;

- other combustible substances that violate the structure of the material.

Even a small percentage of such additives over time will adversely affect the quality of pasting at home or other premises. Also, when selecting glue, it is taken into account that it will be used for outdoor work or inside the building. Houses glued with polystyrene from the outside are exposed to low temperatures, and the product must be frost-resistant.

The instructions for the adhesive mixture always indicate what types of substrates it is suitable for. It is necessary to clarify whether the product is suitable for application on concrete, wooden, metal surfaces. If necessary, the glue should be held securely on the putty, other heat-insulating materials (isolon, EPS). You can use dry or “wet” glue to fix the foam sheets together.

to contents ↑Types and manufacturers of adhesives

The construction market is filled with different formulations for sticking foam. Usually it is recommended to use:

- foam, foam;

- liquid Nails;

- powder masses;

- sealants, etc.

Dry mixes

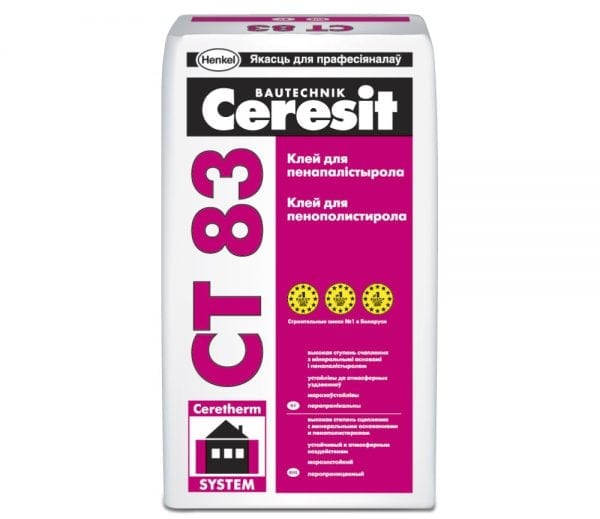

Such materials are sold in large bags (up to 30 kg) and diluted with water. In appearance, the powder resembles putty or plaster, but contains more durable adhesive components. This method of wall insulation will be the most budgetary. Typically, mixtures are prepared on the basis of cement, gypsum and a number of polymer additives. Reliability, durability of glues leaves no doubt. Quality brands are:

- Ceresit ST-83;

- Knauf Perlfix;

- Avangard-K;

- Primus

- "Volma";

- Armierungs-Gewebekleber.

Most of the mixtures are suitable for gluing polystyrene outside and inside the house - to concrete, to wood and other materials. From them it is necessary to prepare the adhesive solution by adding the amount of water specified in the instructions. Consumption per 1 square. m surface - about 1.5-2 kg of the finished mass. Many compounds can additionally close the joints between the plates, in addition, they are suitable for puttying walls.

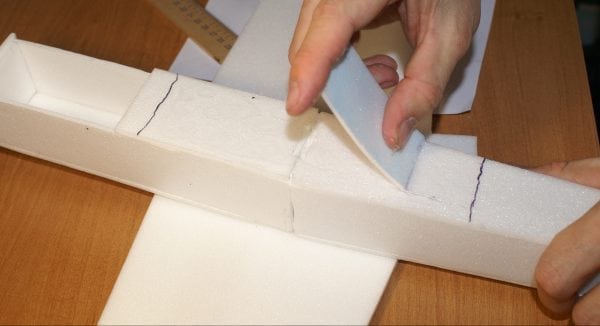

To improve adhesion to the base, the walls are cleaned, dried, primed before starting work. Mix the solution carefully, it should not be lumps. Glue is applied with a spatula in strips or in a continuous layer - along the edges, in the center.

to contents ↑Polyurethane adhesive foam

What is the best way to stick foam on a wall? The polyurethane compound is ideal for this purpose. On sale there are even special foams marked "for expanded polystyrene". They can be applied on vertical, horizontal bases, used for indoor and outdoor use. Famous brands are Tytan Styro 753, Penosil, Ceresit CT-84 Express.

Polyurethane adhesive easily connects plastic and all its derivatives (foam plastic also applies to them) with any surfaces. It allows you to fasten blocks to OSB-plate, metal, concrete, plaster, wood, aerated concrete, foam blocks. Advantages are obvious:

- high speed mounting plates;

- moisture resistance, frost resistance;

- ease of use;

- low consumption.

The bonding of materials with polystyrene foam will be reliable, the adhesion rate is maximum. It is not necessary to spread glue, it is sold in ready-made containers. The consumption of one package is 10-15 square meters. m plates. The polyurethane in the composition allows you to fix the materials after 20-30 minutes, and you need to hold the foam with your hands no more than 20 seconds.

to contents ↑PVA

Is it allowed to stick polystyrene foam with PVA? The choice is popular due to the low cost of the product. Unfortunately, the degree of fixation of this glue is insufficient to create long-lasting insulation. But PVA can play a role: it will serve as a filler of voids in the wall, and dowels will improve the quality of fastening. Dual technology will save and complete the job without delay.

to contents ↑Some practice bonding polystyrene to metal on PVA. You can do this, but the expense is very large, and burlap is used as a layer.

Polyurethane foam

Is it possible to stick foam on the mounting foam? Professionals and beginners respect it for its efficiency, excellent adhesion to the surface and the reliability of the glue line. It is convenient to work with foam; it is easily sprayed from a cylinder. Nevertheless, the purpose of this tool is somewhat different. It is used to seal grooves, crevices, and reinforce concrete structures. Of course, you can fix polystyrene plates to iron, concrete, brick with foam, but there are a number of minuses:

- all operations will have to be performed very quickly, the material will freeze soon;

- after hardening, it expands greatly in volume and can deform thin foam, cause curvature of a home-made structure;

- due to uneven expansion in some areas, voids are able to form, which affects the quality of thermal insulation;

- material consumption per square meter is large, the cost of repair will be far from budgetary.

Many polyurethane foams also contain components that are corrosive to the foam and are not suitable for it. Therefore, the correct procedure is as follows:

- immediately determine whether the product is suitable for polystyrene foam;

- glue the blocks on the walls with a different glue;

- the joints between the foam plates to fill with mounting foam.

It is possible to reduce the consumption of foamy material by using a glue gun; saving on its purchase is impractical.

to contents ↑Liquid Nails

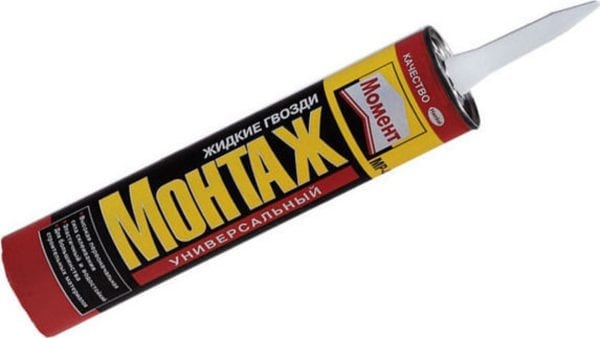

What glue do professionals use most often? Often, craftsmen prefer liquid nails "Installation Moment", Dragon and several others. All work with the participation of this tool will be performed quickly and efficiently, because setting with the surface, solidification speed and service life are in the optimal ratio. By the strength of the compound, liquid nails are second only to polyurethane adhesives. Therefore, for complex substrates (for example, for metal sheets), experts advise using these two tools together.

to contents ↑To optimize adhesion, the surface should be cleaned, degreased, and primed if necessary. So you can stick polystyrene even to the ceiling. Due to the high cost, liquid nails are usually used in small areas.

Joining foam to different surfaces

In order to properly stick polystyrene foam, it is important to know the specifics and properties of the base material. There are a number of features that must be considered during installation.

Concrete

Often, masters try to save money when insulating concrete walls with foam, without making a crate. Indeed, it is possible to glue the material directly to the wall. For this purpose, you will need such tools and consumables:

- primer;

- putty knife;

- cement;

- sand;

- glue;

- drill.

To improve the grip quality do the preparation. The surface is cleaned of dirt, dust, stains. Unstable areas will have to be putty again after removing the old coating. At the end of the preparatory work, the wall is primed. Usually, dry glue mixes are bought to connect the foam and concrete. They are diluted with water according to the instructions, the proportions are indicated in it. They are mixed with a nozzle using a drill, and a construction mixer is also suitable. Next, wait for the time indicated on the package to infuse the solution.

How to glue foam with concrete? The tips are as follows:

- in the presence of small defects, minor irregularities, the glue is applied in continuous strips, 2 cm away from the edges;

- if the wall irregularities are more than 2 cm, lubricate the foam with stripes with gaps (this will remove excess air);

- be sure to apply the product in the middle of each plate;

- they press the material against the wall, immediately remove excess glue with a rag.

to contents ↑Additionally, it is recommended to mount with dowels - in the center, in the corners. It is also possible to attach the material with sealant or liquid nails and dowels, the seam will also be reliable. Instead of the specified materials, a special polyurethane adhesive, which is applied using a gun, is suitable.

Metal

How to properly attach thermal insulation material to an iron surface? For most of them, the same rules apply. Styrofoam, extruded polystyrene foam, polystyrene foam are attached to the metal using burlap. After docking with the latter, there will be no problems with repair; almost any glue can be used. If you want to glue small areas inside the house, you can use double-sided tape at all. Another important nuance is the mandatory cleaning of the wall from rust - if this is not done, the adhesion of the adhesive will decrease.

Styrofoam is attached to a metal base with the following means:

- aerosol adhesives;

- silicone sealants;

- polyurethane foam and mounting;

- dry polymer blends.

An excellent option would be to work with a one-component polyurethane adhesive, which is sold in cylinders. It can also be made in the form of glue-foam. If the foam is attached to an inclined or uneven metal wall, this glue is the master's best choice. It is also used without burlap in cases where it is impossible to attach the latter. There should be at least 5 points of any glue on the foam sheet. Dry mixes after dilution are applied in strips, as described above for concrete surfaces.

to contents ↑Tree

In general, the procedure for gluing polystyrene onto wooden substrates is similar. We are talking about fastening to plywood, OSB boards, lining, boards. Features of work are as follows:

- Before pasting the walls, it is important to completely clean them from debris and dust, if necessary, wash and dry;

- priming is mandatory, for an old tree - 2-3 times;

- if the foam is attached under the windows, a reinforcing mesh is first attached to the tree (using a construction stapler);

- voids in the walls and cracks are filled with mounting foam, after a day its excess is cut off;

- protruding sections, knots are squeezed;

- the remains of the old varnish are completely removed from the tree, they destroy the foam.

The adhesive mixture is distributed evenly on the foam sheet, strips, departing from the edges. Next, draw strips on the diagonals. Any glue suitable for polystyrene foam and containing additives against mold, mildew, can be used.

to contents ↑Other surfaces

In some cases, insulated walls may be lined with less popular materials. It happens that you need to glue the foil to the foam, this is usually required when buying a foil insulation. The gluing process can be difficult, because many products simply roll off the surface, while more reliable ones dissolve the foam. Solving the problem is simple. It is necessary to sand the foil side with sandpaper, after applying these types of glue:

- any foam;

- epoxy adhesive;

- liquid Nails;

- "Titanium Universal."

For reliability, many use a construction stapler. His staples will certainly fix the structure on the balcony or other areas of the house. Fastening of foam to plastic (panels, blocks) is carried out using polyurethane adhesive, foam, epoxy adhesive, coupled with dowels.

In the manufacture of crafts, it is often necessary to attach paper to polystyrene. Often the fabric is attached to this material, which is not easy to do without dexterity. If you pour too much glue, it will come to the surface and the appearance of the product will suffer. It is recommended to use the universal adhesive "Titan", epoxy adhesive, polyurethane products in aerosols. They are applied in small drops, after which they press the paper or fabric, gently smooth. PVA is also suitable for paper, but it is not suitable for thin fabrics.

It is possible to glue the oilcloth on polystyrene foam by any universal means that does not come into "conflict" with the structure of the material. If the structure is large, it is better to use aerosol glue or quick setting solutions. The right choice of glue guarantees high quality of the finished product and its durability in work!