Any plumber knows about the method of cold welding radiators. Not every time there is the opportunity to apply hot welding, but repairs using special adhesives are almost always available. Cold welding for heating pipes is useful when leaking, it will help to eliminate the problem quickly and with your own hands.

- Cold welding - what is it, application for heating system

- Cold Welding Composition

- Types of welding

- Ways to use

- Mix temperature

- Advantages and disadvantages

- Types and manufacturers

- Instructions for cold pipe welding

- Security measures

- Repairing cast iron and other types of radiators

Cold welding - what is it, application for heating system

Metal bonding technology was used in antiquity; as a result, one-piece joints were created without the risk of oxidation of parts. Cold welding is understood to mean the technological process of joining products without additional heating, as a result of which their surfaces undergo plastic deformation. The latter destroys the oxide film, which no earlier prevented metals from docking. Welding occurs in a short period of time as a result of setting. In appearance, this adhesive resembles putty, made on the basis of epoxy resin.

Now cold welding is widely used to connect such metals:

- cast iron;

- stainless steel;

- copper;

- tin;

- aluminum;

- nickel;

- lead.

Using welding glue, it is possible to repair steel and aluminum batteries, cast iron radiators, bimetal radiators. Polymeric products for the pipeline can also be brewed in this way. We are talking about propylene pipes, which are used for installation of a heating system. With the exact observance of the technology, it is possible to seal the pipe, riser, radiator with any defect, although the joint strength will be somewhat inferior to that after electric arc welding.

to contents ↑Cold Welding Composition

Glue for metal and plastic is made of epoxy resin - a polymer having high strength characteristics. It is this resin that is responsible for the uniformity, plasticity of the mass, the ability to repair even minimal cracks and fill the pits. Epoxy can thicken only upon contact with the hardener that comes with the kit (in some products, it is in solid form, activated after exposure to air and mixing).

to contents ↑The composition of cold welding has various fillers that optimize the technical properties: steel powder (hardening additive), sulfur, plasticizers. When repairing radiators, it is necessary to pay attention to such additives; they must be putty.

Types of welding

All funds related to this type are divided into plastic and fluid. The latter are necessarily two-component mixtures - one bottle contains an epoxy resin with additives, the second contains a hardener. Plastic masses are sold in tubes, bottles, jars, they can cover the pipe or radiator without dilution. The mass in appearance resembles plasticine, consisting of two bars, which must be mixed together by kneading with your fingers. It is possible to separate a small piece of the mass, and save the rest until the next need.

to contents ↑Ways to use

To repair the pipes, you need to prepare everything you need - the tool itself for welding, acetone or alcohol, sandpaper, rags and clamps. The method of sealing radiators differs slightly depending on the type of welding - liquid or plastic. It is important to choose a suitable product that is suitable for pipes under pressure (metal or polypropylene). Next, you need to prepare, mix the material, and with liquid means should work faster.

Welding applications:

- simple sticking of the defect with a piece of mass, flattened and wrinkled with your fingers;

- the use of special fiberglass fabrics, threads for wetting with epoxy followed by wrapping with rubber, wire or without it;

- sticking to a large defect coated with a metal patch.

If the flow is strong, you can make the composition even more durable with your own hands. You need to take any aluminum or bronze part, grind it a little over the paper, getting a metal powder. It must be added to the epoxy mass, which will then be impregnated with threads of thread or fabric.

to contents ↑Mix temperature

Depending on the exact composition and specific from the manufacturer, the temperature range of the application of welding can vary greatly. Most products can withstand freezing, for example, Mastix glue will not lose its properties even at -60 degrees. The vast majority of cheap epoxy works only up to +150 degrees, so you can use them for welding radiators and heating pipes (the heating system is usually operated at + 95 ... + 110 degrees).

to contents ↑Higher quality products can withstand up to +260 degrees, but there are also high-temperature mixtures - they are used even in extreme conditions (up to +1300 degrees). Although it makes no sense to spend money on the purchase of such funds, you can buy a simple low-temperature composition.

Advantages and disadvantages

The technology eliminates pipe leakage with high reliability. This procedure is safe to perform, which cannot be said about conventional welding. Other benefits are:

- convenience, ease of methodology, even for beginners;

- excellent weld quality, which depends mainly on the type of material, and not on the speed of work;

- lack of need to purchase special tools, equipment, machinery and expensive materials;

- minimum energy consumption;

- fireproof, anti-explosive properties of epoxy;

- low cost of repair;

- the availability of cold welding - adhesives are sold in any store.

Technology also has disadvantages. Welding of this type is not designed for too high loads - pressure, strong heating. Therefore, in case of a serious defect in the pipe or radiator, it is better to use hot welding or completely change the area. It is important to observe the preparation measures - otherwise the quality of the weld will decrease. The durability of cold welding is lower than that of standard welding - repaired pipes will not last for many years, but will require new repairs. In fact, such repairs are considered by specialists as a temporary measure.

to contents ↑Types and manufacturers

Typically, cold welding is used when it is financially impractical to use the hot method or it is difficult. Such situations occur when a minimal defect appears, damage to the overall product, risk of serious internal stresses in the pipe.

The following types of tools can be used for repairs:

- universal - used for gluing metal, plastic, stone, wood, glass, concrete and most other materials;

- automobile - if the material indicates that it can withstand high temperatures, then it is allowed to use it in pipe repair;

- for plastic - usually the heat resistance of such products reaches +260 degrees and above, therefore they are also suitable for work.

Not suitable means marked "for wood", "for plumbing." They, as a rule, are not heat-resistant, and the adhesion quality will be lower. It is better to find specific welding for working on metal, plastic with a clear indication of the temperature regime. There are even super-water resistant tools for working under water, they can also be used for cold welding.

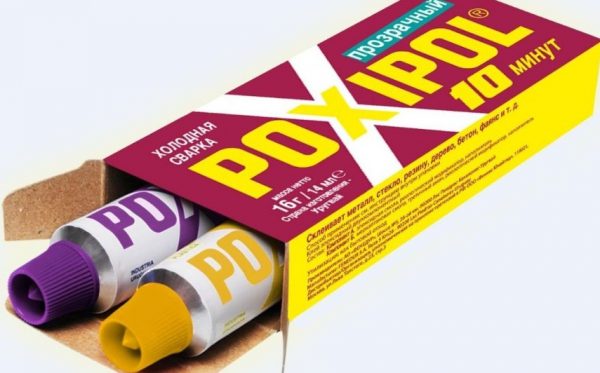

Domestic compositions are cheaper than imported, but not inferior in quality to the latter. Just do not take the cheapest welding, it will certainly give a low quality of the weld. The most popular means are:

- Hi-Gear. Universal glue, it is often bought by car owners to seal elements exposed to severe stresses. Such glue will help eliminate any leakage in the heating system.

- "Titanium". Suitable for any materials, does not deteriorate from exposure to water and high temperatures.

Also in demand are weldings ABRO, Polymet, Alma, Wurth Liquid, Permatex Cold Weld.

to contents ↑Instructions for cold pipe welding

First you need to qualitatively prepare the foundation. To do this, all areas on which the resin will be applied are cleaned of rust, dirt, old paint. You can process them with sandpaper to immediately remove all contaminants. You should not try too hard, otherwise deep scratches will remain on the surface. But minor scuffs will come in handy - they will enhance adhesion. Immediately prior to welding, the parts must be degreased with a solvent (usually acetone) or washed with detergent. If possible, you need to dry the joints with a hair dryer - heating will improve grip.

The glue is prepared according to the instructions. To produce a liquid adhesive, a strictly measured amount of hardener is added to the resin. The lifetime of the composition is also indicated in the instructions, then its polymerization begins. Usually the period is 10-15 minutes or a little more. This time can be slightly prolonged by cooling the product.

Plasticine mastics are prepared by kneading with hands, after putting on gloves and soaking them with water. The required amount of material should be cut from the rod, the rest of the mass removed. It is necessary to cut only strictly across, otherwise the ratio of epoxy and hardener will be incorrect. When ready, the color of the mass will become uniform, while it will heat up due to heat generation.

Repair is carried out in this way:

- apply glue to the place of the future joint, directly into the hole, to ensure the penetration of the mass deep into;

- the second option is to wind up fiberglass, fiberglass, cover with a liquid composition that has already begun to thicken a little;

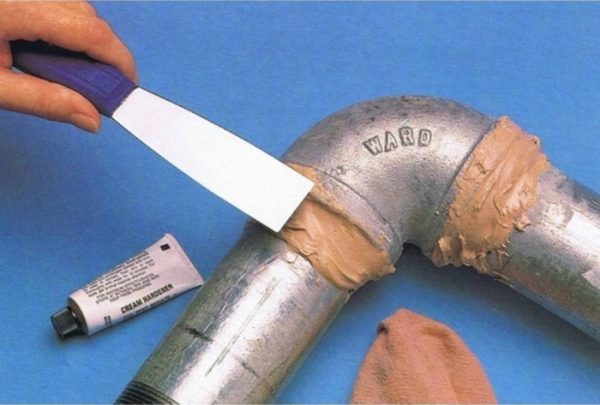

- smooth the product from the outside with a small spatula or other flat device, slightly moistening it in water;

- within a few minutes you can change the position of the mixture;

- if the hole is too large, a metal patch will have to be planted on it (directly for cold welding);

- fix the area for 15-60 minutes, depending on the instructions, using a clamp;

- if possible, it is impossible to expose the joint to intensive loads for 1-24 hours, although for most weldings 1-1.5 hours are enough.

If the repair is carried out in a room with a low temperature, the glue should be rolled up into a ball and the mass inside should be warmed up to + 40 ... + 50 degrees. The holding time of the ball should not be longer than the life of the mixture (usually it does not hold more than 4 minutes). To effectively warm the ball, it must be made with a mass of at least 50 g. It must be remembered that for repairing complex joints and assemblies it is better to immediately use hot welding or replace parts, a cold joint may be unreliable.

to contents ↑Security measures

After drying, the material is safe for humans, but care must be taken when working with it.All work is carried out with gloves, preventing direct contact of the epoxy with the skin. Do not use a knife for food to cut resin. Upon contact with the mass, the skin is washed with soap and water.

Repairing cast iron and other types of radiators

Working with radiators is similar to sticking defects on pipes. The surface is cleaned, degreased. You can use alcohol for this purpose, applying it with a cotton swab. Next, take a ball of resin about 2 cm in diameter, knead it, mixing the components. Press the resin to the place of damage, smooth it, hold it with a rag or clip.

Usually 30-40 minutes are enough for polymerization, but it is better to use the battery after a day, not earlier. Naturally, the water supply must be turned off before repair. If you want to remove the fistula, you need to take fiberglass and a liquid product, wrap the area and glue it securely.

Cold welding is an excellent temporary measure until the end of the heating season. It will help eliminate leaking pipes or radiator quickly and without hassle!