Many construction and repair work is carried out using sealants. Such tools are suitable for metal and plastic, brick and stone - they help to repair seams, remove cracks, and protect structures from water penetration. If the surface is exposed to heat during operation, a heat-resistant sealant will be required. The material does not deteriorate from exposure to high temperatures, because it can even be used to repair fireplaces, stoves and gas stoves.

- Features of heat-resistant sealants

- Sealant Applications

- The main properties of sealants

- Additional features of sealants

- Main types of high temperature sealants

- Heat Resistant Sealants

- Heat Resistant Sealants

- Silicone seals

- Adhesive claddings

- Work with sealant

- Metal application process

- Work with thermal sealant for stoves and fireplaces

- Top manufacturers

Features of heat-resistant sealants

A sealant is a special composition capable of creating a durable insulating layer on the work surface or between parts. Thermo-sealant is the most reliable tool, and the requirements for it are very serious. The material is made on the basis of heat-resistant silicone - a polymer that is a transparent elastic mass. Other substances that enhance the operational properties of the sealant (minerals, metal powder and others) are also introduced into the composition. There are also high temperature epoxy adhesives - two-component products, the components of which are mixed before application.

to contents ↑Sealant Applications

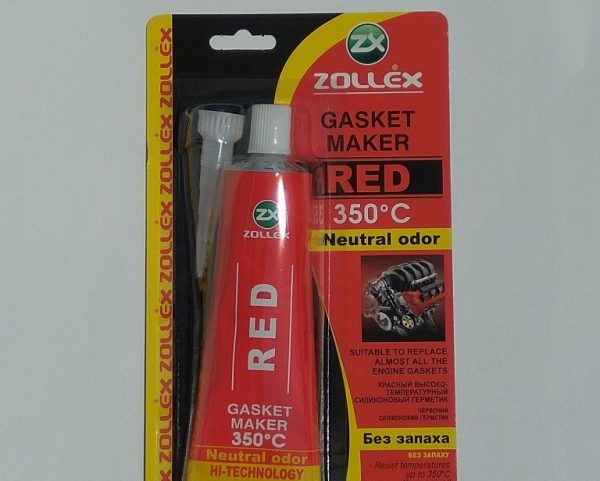

Materials are widely used in everyday life, industry. Sealants are involved in the installation of heating pipes, pipelines for supplying cold and hot water, because they can withstand not only heating, but also temperature drops up to minus. Heat-resistant sealants are suitable for stoves, a chimney in a bath, sauna, private house. A special automobile composition is useful in strengthening and sealing gaskets, engine seams, headlights, a car muffler, an exhaust pipe.

With the help of sealants, it is possible to repair heating household appliances - a kettle, hob, oven and even moonshine. Usually, food thermo-sealant is used for this purpose, which is harmless in contact with food, taking into account heating. The same type of material is used when repairing equipment in food production, factories, and catering establishments.

Other areas of operation of sealants:

- protection of stainless steel products, alloys from moisture penetration;

- prevention of damage to complex equipment operating in the air, aggressive conditions;

- restoration of electrical engineering, electronics for pouring elements and electrical insulation;

- protection of car parts from corrosion;

- sealing welds of gas boilers;

- repair of fireplaces, ventilation, fire structures.

The main properties of sealants

Silicone sealant is a heat-resistant material, the ability to withstand high temperatures is its hallmark. Conventional heat-resistant sealants use up to +350 degrees, but there are compositions that can withstand +1500 degrees, therefore they are considered refractory. Materials are non-flammable, non-combustible, non-explosive.

Other properties of sealants:

- ability to withstand high loads without loss of sealing qualities;

- plasticity and elasticity (due to this, the seam does not crack after drying);

- good adhesion with any materials (provided a dry surface at the time of application);

- moisture resistance;

- long working life and long storage period;

- non-toxic, safe for humans, the environment and animals.

Almost any sealant is oil-resistant or gas-oil-resistant - it does not deteriorate from contact with oil products. Also, most products are immune to the effects of weak acids, alkalis, other chemicals and household chemicals.

The negative properties of sealants can be attributed to the fact that they do not bond well with wet surfaces, the level of adhesion drops significantly. Also, before use, the base should be treated from small debris, otherwise the seam will not serve for a long time. Some products do not harden quickly, and several days will pass before use. The sealant can not be painted, the paint does not hold on it, although there are colored products on sale (red, black and others). It is not recommended to seal up too large gaps with thermo-sealant, since in the depths the material may not harden.

to contents ↑Additional features of sealants

Thermo-sealants have a number of related properties, which are sometimes no less in demand. So, most of them are resistant to UV radiation, therefore they are suitable for outdoor applications, for example, for gluing a defect in a chimney, roof passages. Sealants are frost-resistant, which makes them indispensable for the repair of baths, stoves and fireplaces in country houses that are not heated all year round. The compositions after application do not crack during vibration, due to which they are used for restoration of machinery and equipment.

to contents ↑Main types of high temperature sealants

There are various types of sealants on the market with the ability to withstand high temperatures. To close up defects on the masonry, it is better to buy those that contain silicates and silicone. Tools are packaged in small cylindrical cartridges that are convenient to insert into the mounting (glue) gun.

Also on sale you can find small packages in tubes resembling paste, which are used like any ordinary glue. A variety of colors allow you to choose the composition of the color of the base material to make the “patch” aesthetic or completely visually invisible. All sealants are divided into heat-resistant, heat-resistant, sealing and with facing properties.

to contents ↑Heat Resistant Sealants

The basis of such funds is silicone, they withstand up to +350 degrees. To achieve such resistance to heating, iron oxide is also introduced into the composition, therefore, the main color of the mass becomes orange. Some products contain acetic acid, they are categorically not suitable for iron - creating an oxide film, sealants will not provide sufficient adhesion. But for aluminum, other non-ferrous metals and stainless steel they can be used, although for any metal it is better to purchase an acid-free composition.

Typically, heat-resistant sealants are used for applying to the outer walls of fireplaces and stoves. They are also suitable for open areas where atmospheric factors and ultraviolet will affect the seam, for example, for roofing from corrugated board, tiles. You can use the compositions to eliminate cracks in the chimney or car parts. The thermal resistance limit is always indicated on the packaging. It must be remembered that +350 degrees is the upper limit of a short-term temperature increase. Constant heating should not exceed + 250 ... + 270 degrees.

to contents ↑The polymerization of the sealant takes several hours, some heat-resistant products harden only after 1-2 days. The closer the expiration date, the faster this process occurs. Ideal conditions for the polymerization of the sealant are considered temperature + 23 ... + 25 degrees, humidity 50%. Other conditions will slow down or accelerate the complete curing of the material.

Heat Resistant Sealants

Such products contain silicates, therefore they are designed for more serious heating - up to +1500 degrees, and even direct exposure to the flame is possible. Repair with heat-resistant sealants should be a cushioning layer between bricks, cast-iron elements of the furnace masonry, seams of the combustion chamber, defects in heating boilers. Sealants do not lose their properties even with extreme heat, but with open flame, you need to find in the instructions a direct indication of the manufacturer for this possibility.

The color of the heat-resistant sealants is usually black, gray due to the presence of silicates. They adhere perfectly to any materials, and yet it is recommended to sandpaper the surface before application. Performance of work should be carried out at a temperature close to +20 degrees. After drying, the seam will be tough, since such sealants are not very elastic. It is better not to use them on products subject to vibration, but for buildings that have already shrunk, they are perfectly suitable.

to contents ↑Silicone seals

On sale you can also find semi-liquid silicone paste in red or blue. As it hardens, it forms an elastic seam that can stretch 2 times. Such sealants are used for new masonry, which are subject to strong shrinkage. Seals can also be used to cover the sandwich chimneys from the outside. The means do not withstand large heating - they work only within the range of -40 ... + 250 degrees. The maximum depth of the seam should not be more than 6 mm, application is carried out at + 5 ... + 30 degrees. The most popular brands of silicone sealants are Titanium, Moment-Germent, Penosil.

to contents ↑Adhesive claddings

Materials with adhesive abilities are used if the masonry is covered with a network of cracks, because it is impossible to treat the entire area with an ordinary sealant. Facing compounds penetrate perfectly into the narrowest and deepest cracks, safely hiding them. After repairing the fireplace, the stove will acquire a more aesthetic appearance. Typically, such mixtures are sold in finished buckets or in bags in the form of a dry powder. The heat resistance of the facing compounds may be different:

- mixtures based on kaolin dust, chamotte - up to +400 degrees;

- one-component adhesives with mineral additives - up to +800 degrees;

- mastics for gluing tiles, stone - up to +1000 degrees.

Work with sealant

For the convenience and speed of applying the product, you should immediately prepare the necessary tools. This is an assembly gun (if the sealant is sold in the form of a cylindrical cylinder), a gas burner, a spatula made of rubber, a clerical knife, paper tape, gloves. A gas burner is only required when using heat-resistant sealants.

Metal application process

To begin with, any surface should be carefully prepared. It is treated with sandpaper, other abrasive material to clean off rust, polyurethane foam and improve the quality of adhesion. Next, the base must be washed and degreased with alcohol, completely dried. All adjacent areas are covered with masking tape.

Before work, put on gloves and load the gun. The upper part of the tube is cut off, then a cap is put on it. The cartridge is inserted into the gun and sealant is applied. The procedure is as follows:

- squeeze the product into place of the defect;

- the seam thickness cannot be made larger than indicated in the instructions;

- the applied mass should completely cover the crack;

- immediately after extruding, smooth out the sealant with a spatula, it is also possible to remove the excess composition before solidification (this will be problematic as it hardens);

- heat-resistant products dry under normal conditions, heat-resistant products are dried in stages, with heating;

- you should wait time until the full hardness of the composition is reached, after which you can begin to operate the parts.

to contents ↑

Work with thermal sealant for stoves and fireplaces

Sealing the gaps between the bricks is carried out especially carefully to achieve high quality and maintain an aesthetic appearance. The surface of the brick can be covered with masking tape so as not to get dirty, leaving only cracks or seams open. The nose of the tube is cut so that the hole is beveled, and its diameter in this case becomes less than the width of the seams. After installing the tube in the gun, you can begin to work:

- to clear a surface of dirt, to process with an emery cloth that will help to strengthen adhesion;

- degrease the base, dry with a building hair dryer;

- stick masking tape;

- fill the gaps with sealant, leave to dry for a day;

- burn the heat-resistant sealant with the flame of a gas burner, after which it will gain its properties.

Immediately after completion of work, the furnace must not be lit at full power. It is warmed up gradually so that the sealant does not crack.

to contents ↑Top manufacturers

It is better to buy products from trusted manufacturers - their quality is usually higher. Low price should alert - heat-resistant products can not be too cheap. Otherwise, organic substances may be added to them to reduce the amount of silicone. The strength of such a material will be much lower, as well as elasticity.

Such brands have proven themselves well:

- Moment Germent High Temperature. Withstands up to +315 degrees, can be used for auto repair, heating systems, perfectly fills grooves and cracks, suitable for metal, wood, stone, glass, plastic.

- ABRO. Sealants of this company are sold in a large assortment, in different colors, with different technical characteristics. Within a few seconds, the products create gaskets, while possessing the highest strength.

- Penosil. The Estonian brand produces material for filling joints, cracks, which withstands up to +1500 degrees of heating.

- Macroflex. Refractory sealants of this brand are used for joining parts and repairing defects on products with low mobility, since the connection will be rigid. Withstand temperature + 1200 ... + 1500 degrees.

Also excellent quality is known for Soudal, Krass, Titanium sealants. All these tools can eliminate the need for expensive repairs or shifting stoves, fireplaces. With strict adherence to the instructions, you can get a reliable connection by doing all the work yourself.