The word "resin" usually means a thick, viscous substance, sticky to the touch. Resins are natural (e.g. gum, rubber, amber) and synthetic. The last group includes a wide variety of materials manufactured by industry. They are much cheaper, easy to use, and highly reliable. So, in the XIX century, phenol-formaldehyde resin was first produced, this material remains at the peak of popularity now.

- Resin properties

- Material application

- Phenol-formaldehyde resin production

- Material damage

- Phenoplasts

Resin properties

Phenol-formaldehyde resins are synthetic masses from the group of phenol-aldehyde resins having the properties of thermosets. The equation and formula of the material is C6H3 (OH) -CH2-] n. The product was developed by heating a mixture of formaldehyde (formalin) and phenol. The fact that the material is obtained by the reaction of these components was revealed by a scientist from Germany A. Bayer in 1872. As a result of the interaction, water and a polymer were formed, although the latter was rather fragile, and the liquid quickly passed into a gaseous substance. Subsequently, the method of obtaining funds was improved by adding wood flour. Now the finished product includes various fillers that improve its properties.

The characteristics and distinctive qualities of phenol-formaldehyde resins are as follows:

- by structure - liquid or solid oligomers;

- the educational environment is acidic, alkaline;

- excellent electrical insulation;

- high resistance to mechanical stress, damage;

- corrosion resistance;

- solubility in hydrocarbons, ketones, chloride solvents, alkalis.

A feature of the material is its transformation into a thick polymer with a microheterogeneous structure after complete curing.

to contents ↑Material application

Phenol-formaldehyde-based resin is used in various sectors of the economy. Of it make plastic of different types:

- with sulfonated curing - carbolithic;

- during curing with lactic acid - neuro-leukorite;

- with the participation of hydrochloric acid - resol.

Phenolic resin is used for the manufacture of adhesives and varnishes, including adhesive brand BF. It is used to create sealants as a structural binder, in the production of plywood, chipboard. Formaldehyde resin is used to fill and impregnate fabrics and other materials.

With the participation of the product, various products of general and special purpose are obtained:

- brake pads for trains, parts for cars, metro escalators;

- abrasive tools;

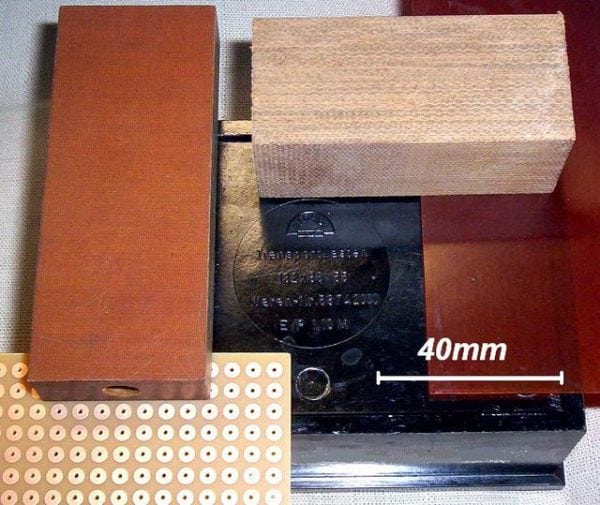

- plugs, boards, sockets, counters, motors, terminals and other electrical products;

- cases of telephones, cameras;

- radio products, including capacitors;

- military equipment and weapons;

- unheated elements of kitchen appliances, utensils;

- textolite and getinax - materials for further processing;

- jewelry, haberdashery, souvenirs;

- balls for billiards.

The material is not used for the manufacture of containers that are in direct contact with food products, especially those intended for heat treatment.

to contents ↑Phenol-formaldehyde resin production

Material refers to polymers obtained by the polycondensation process. It can be made from methane and methanol by conversion to formaldehyde and further compounds with phenol. The technology is as follows:

- take a solution of formaldehyde 40% in an amount of 3 ml;

- combined with 2 g of crystalline phenol (according to Gosstandart, it can be replaced with 4 ml of a solution of carbolic acid, it is a liquid concentrated phenol);

- add 3 drops of hydrochloric acid to the mass;

- the mixture boils, after which it turns into a transparent mass like glass (resol);

- if it is required to slow down the process, then the dishes with the mass are cooled;

- the resol is easily soluble in alcohol; an experiment can be carried out to clarify the quality of the resulting mass;

- if you leave the product for a longer period, it will become viscous, non-fluid and stop dissolving in alcohol - it will turn into a more plastic material resitol;

- at the end of the work, the container is placed in boiling water, as a result, the resin hardens, becomes literally stone, becomes red.

The finished product does not burn, but slowly charred. In this case, the fire will become yellowish, an unpleasant smell of phenol will be felt. The technical conditions for stopping the reaction are as follows: at any stage (until the final cure), alkali can be added, this will stop the polymerization process.

to contents ↑The state standard also denotes the procedure for obtaining other substances during the production of phenol-formaldehyde resin. So, with an increase in the amount of phenol, novolak can be obtained. An increase in the concentration of formaldehyde allows you to make bakelite. When replacing formalin with acetone with the participation of hydrochloric acid, bisphenol will be obtained.

Material damage

Despite the advantages, resins of this type can cause great harm to humans and the environment. Their danger is that toxic components are used in production. Phenol and formalin are poisonous, and the latter is also considered a strong carcinogen. Both substances have the following harmful effects:

- inhibit the nervous system;

- cause rash, dermatitis;

- provoke allergies and bronchial asthma.

What regulatory documentation governs product manufacturing? SanPiN regulates the permissible amount of migration of these substances into finished products. They are 0.05 mg / L for phenol, 0.1 mg / L for formaldehyde. The environmental problem is also the disposal of products from such resins. Equally important is the protection of workers in industries where they are produced and processed. This phenol formaldehyde is very different from environmentally friendly epoxy resins.

to contents ↑

Phenoplasts

Under phenoplastics understand plastics, which are obtained by combining phenol-formaldehyde resin with different fillers. The process proceeds at high temperature, and the type of filler depends on the type of final product. Phenolic-bakelite adhesive composition, various plastic products for everyday life and the national economy also belong to phenoplastics. Phenoplasts make parts for equipment and cars. Currently, production methods are so advanced that only trace concentrations of harmful substances are present in the finished product.