If the ceramic coating will be used in difficult conditions, it must be glued to a specialized tile adhesive with enhanced strength. Its properties should provide excellent tolerance to heavy loads, exposure to high or low temperatures and other damaging factors. Such means include adhesive for tiles "Strengthened Strength", which can easily withstand even severe vibrational, thermal, chemical loads.

- Features of Reinforced Solutions

- Area of use

- Main characteristics

- Varieties

- Preparation and application

- Advantages and disadvantages

- Storage

- Useful Tips

Features of Reinforced Solutions

Strengthened Kreps glue is produced in bags of 5 and 25 kg, is a dry cement-based construction composition. It also contains sand, modifiers, plasticizers, while the total fraction size does not exceed 0.63 mm.

The main difference between the “Reinforced” means and the “Standard” category is that the technical characteristics of the former are seriously improved. In particular, with proper dilution, the adhesion of the solution will be at least 1 MPa, while with standard products it rarely exceeds 0.3-0.8. Also, this tile adhesive has high frost resistance - up to 35 cycles of freezing, defrosting and more.

Other differences of the category “Reinforced”:

- extension of time for work in general and for adjusting tiles;

- minimal creep even when laying large elements (up to 0.5 mm);

- maintaining a large range of temperatures;

- an opportunity to apply for external and internal works, including, at installation of a heat-insulated floor, facades of buildings, socles, parapets, ladders.

Some manufacturers add Kreps antifreeze to the glue. This helps to tile the exterior of buildings even at sub-zero temperatures (usually up to -10 degrees).

to contents ↑Area of use

Using glue, you can lay various types of tiles: granite, elements of marble, mineral materials, large-format heavy products. The tool is great for finishing with ceramics and these types of tiles:

- floor;

- wall mounted;

- front;

- sidewalk;

- decorative;

- mosaic;

- for a warm floor.

Only when mounting plates larger than 60 * 60 cm at a height of a meter is it recommended to make additional fixation. In other cases, the use of glue "Craps" is enough to secure the finish. Using glue, you can work with tiles on the following bases:

- cement, concrete (including cellular), reinforced concrete;

- cement-lime plasters;

- drywall and plaster;

- tongue-and-groove plates;

- limestone coatings;

- brick, other porous mineral bases.

to contents ↑Scopes of glue are various, it is considered a universal remedy. “Kreps” is used in houses, apartments, offices, helps to finish the floor, walls in industrial buildings, workshops, utility rooms.Useful material for decoration of sports facilities, terraces, outdoor areas, paths, bathrooms, baths and saunas. Water resistance allows it to be used for pool lining.

Main characteristics

The difference between Kreps adhesives in large and small packaging is the weight of the powder mixture, as well as the use of white cement in 5 kg packs (25 kg in gray cement). Other technical parameters are approximately the same:

- solution consumption - less than 3-4 kg / sq. m .;

- dilution standards - about 6.5 liters of water per 25 kg of the mixture, about 1.3 liters -

- 5 kg;

- time for work and adjustment of the position of the tile - 20 minutes;

- the pot life of the solution after readiness is 4 hours;

- the possibility of grouting, base load - 24 hours for walls, 72 - for the floor.

Varieties

Kreps has several modifications. All of them are used depending on operating conditions, type of coating. The difference between adhesives is in the types of additives and their amount, which determines the physical and mechanical properties. Here are the main types of glue:

- "Reinforced." It has a high level of adhesion, allows you to lay heavy porcelain tiles, marble, even on vertical bases.

- Reinforced White. This glue differs only in white, other characteristics are similar to the previous tool. In addition to white cement, it contains the same shade of dye. Most often used for glass, mosaics, light tiles.

- "Enhanced Express." It is characterized by the highest hardening rate, since it includes accelerating drying additives (catalysts). After 4-6 hours you can use the surface.

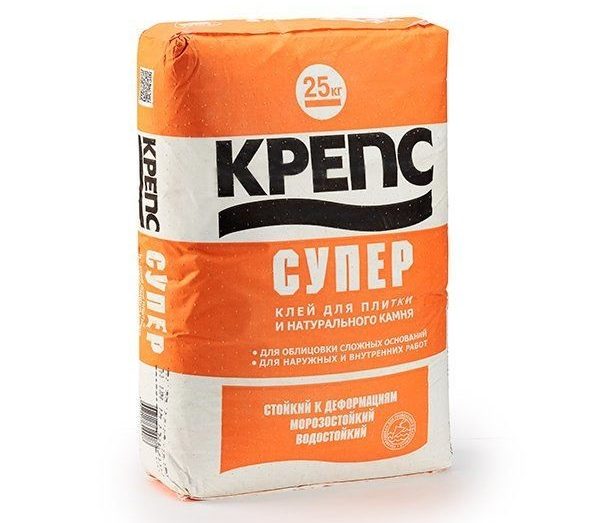

- Kreps Super. Designed to work with glass, mineral, wood, metal base materials. Also, this glue can be used to create underfloor heating, polymer coatings. It is characterized by increased elasticity and enhanced traction.

As for the brands and manufacturers of Kreps glue, the following are considered the best:

- Bergauf Keramik Pro. It is produced in Russia. It can be used in rooms with high humidity. It has a low consumption (up to 2.5 kg / sq. M.), A long viability of the mixture, adhesion of more than 1 MPa, low water absorption - up to 1.5%. The tool has a small thermal conductivity, which is attributed to its disadvantages.

- "Perfect Holder." It is a reinforced adhesive for ceramic tiles and porcelain tiles. Suitable even for the installation of large-format plates. It has great strength because it is reinforced with special fiber fibers. When pasting a vertical surface with a heavy tile, the elements will not slip. Consumption is very small - only 1.5-2 kg / sq. m., frost resistance is enormous (50 cycles of freezing and defrosting). Minus - a high percentage of water absorption (3.5%).

- Mixity. The glue is suitable for indoor and outdoor use, for rooms with any level of humidity. It has excellent fixing ability, therefore it helps to glue even the heaviest tiles. You can put glue in a thick layer (up to 1 cm), making the alignment of the base.

Preparation and application

On the packaging is always indicated the exact rate of fluid that must be added to obtain the finished glue. Usually it takes 6-6.5 liters per large package of powder, but at first it is best to take a minimum amount of liquid (6 l). Water is poured into the container, then the mixture is poured, mixed manually or with a construction mixer at low speeds. Also for this purpose, you can take a drill with a special nozzle. After 10 minutes, the mass is kneaded again, then it is considered ready for use. Use the solution in 4 hours, no more.

When working with any tile, it is very important to properly prepare the base. It should not have differences, bumps, deformation changes. All contaminants, dust are removed from the surface, degreased by washing with household chemicals or treating with alcohol. In order for the adhesion to the base to be ideal, it is worthwhile to additionally apply the Kreps Primer primer. Strongly absorbent, porous substrates are primed twice.

Further, the procedure is as follows:

- apply the product on the base, then level with a notched trowel;

- immediately process only that area that can be pasted with tiles in 15-20 minutes;

- to lay the tile within the specified time;

- press the elements well;

- when laying, monitor the normal dimensions of the tile joints, for which crosses must be correctly installed.

to contents ↑At the end of work, immediately rinse all tools with water. After the glue hardens, it will be an order of magnitude more difficult to do. During work, you need to use tight clothing, personal protective equipment. If glue gets on the skin, it is recommended to rinse it with plenty of water.

Advantages and disadvantages

Glue "Craps" allows you to work where ordinary solutions can not cope. Due to the high quality of adhesion, the tile will not slip even in the most extreme conditions. If you use adhesives with low, medium moisture resistance, frost resistance, low elasticity, adhesive joints will quickly collapse. This can cause tile deformation. The same applies to heat resistance: the use of simple means for laying a warm floor leads to cracking of joints after a short period of time. This is due to the expansion of ceramics when heated, while the glue does not expand.

Thus, the advantages of Kreps glue are as follows:

- preservation of properties during increase, decrease, temperature changes;

- economical spending;

- reinforced strength;

- quick solidification;

- suitability for all types of tiles and substrates;

- good thermal conductivity;

- high moisture resistance;

- the ability to apply where other materials quickly deteriorate, as well as work in the cold (for adhesives with antifreeze);

- refractoriness (for certain types of "Kreps").

The disadvantages of glue are much less. When working, you must strictly follow the instructions, act quickly, because the glue hardens after a short period of time. It will be difficult for beginners to immediately control the process, the thickness of the layer, its uniformity. This is especially important when laying large-format tiles, which, if the layer is too thin, will disappear over time, despite the high degree of adhesion.

to contents ↑Storage

The finished mixture cannot be stored, if it is not consumed in 4 hours, the remainder can simply be thrown away. Dry powder in factory packaging has a long shelf life of 12 months, provided that it is stored on a stand in a dry place.

Useful Tips

Do not start surface operation until the adhesive layer has completely dried. The same applies to grouting: it begins only after 24 hours for the walls, 72 for the floor, otherwise there is a risk of tile displacement. Other tips for working with reinforced glue:

- The larger the tile, the larger the trowels should be at the spatula. For elements of size 15 * 15, the length of the cloves is 6 mm, for tiles 30 * 30 cm - 8 mm.

- The optimum thickness of the glue layer is 4 mm, but for plates more than 30 * 30 cm it is made at least 7 mm. If the floor is laid, it is worth putting a layer up to 9 mm. The main thing is to evenly distribute the glue along the base, it is better to check it with a level.

- It is possible to work at subzero temperatures only with glue in which antifreeze is added. Other adhesives are used at positive temperatures, preferably above +5 degrees.

- Before the final drying, do not wash the floor; contact with water and other liquids should be completely excluded.

- The base should not be subject to shrinkage, deformation. Otherwise, the tile will begin to deteriorate, move away from the surface.

If all the tips are followed, there is a high chance that the work will be done quickly and efficiently. Reinforced adhesives can be used in normal conditions, they always show the best results in finishing work.