Unis is a Russian manufacturer of goods for construction and repair. She produces a huge range of dry mortar, including adhesives for tiles. For 20 years, the brand has entered the list of the most popular on the market, since its products are distinguished by excellent technical characteristics and moderate cost. Tile glue "Eunice" has many varieties, which seriously expands the scope of its application.

- Features and scope of use

- Advantages and disadvantages

- Types of adhesive mixtures from Eunice and technical specifications

- Eunice Plus

- Eunice 2000

- Eunice 21

- Eunice HiTech

- Eunice Granite

- Eunice Belfix

- Unis fix

- Eunice Pool

- Teplokley

- Eunice Horizon

- Rapido

- U 100

- Maxiflex

- Super Plus

- Flow calculator

- General instructions for use

- Surface preparation

- Solution mixing

- Glue application

Features and scope of use

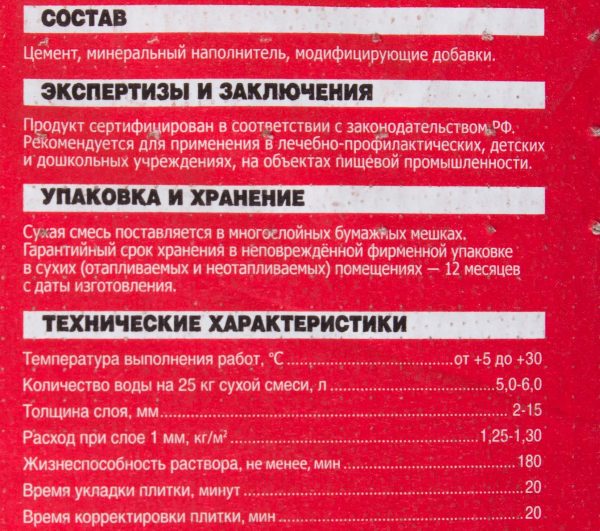

The basic composition of Unise brand tile adhesives is approximately the same. It includes cement and mineral fillers: regular and quartz sand, gypsum, dolomite and others. To improve technical parameters, each product is enriched with various chemical additives: modifiers, plasticizers, adhesion promoters, etc.

The quality of Unis products is not inferior to that of world-famous tile adhesives. All products have the necessary certificates of conformity, confirming their characteristics. Unis adhesives can be used for finishing children's institutions, hospitals, clinics, without violating safety standards.

Many compositions are suitable not only for ordinary tiles, but also for porcelain stoneware, since they have a high degree of adhesion with the following bases:

- gypsum;

- concrete, including cellular;

- cement screed;

- asphalt;

- brick;

- drywall (GWP, GKL, GVL);

- slag concrete;

- aerated concrete.

Some tools are suitable only for interior work, others are also suitable for finishing facades, walkways, socles, terraces, arbors and other types of outdoor objects. There are adhesives for underfloor heating, swimming pools, for various complex substrates. Some tile adhesives can easily glue glass mosaics or natural and artificial stone.

The products form a durable layer that does not deteriorate over time in a dry or wet room. Near building mixtures, you can level the floor with small differences in elevation, other means are suitable for stairs and floors in shopping centers with high traffic. In addition, the use of Unis adhesives is possible in bathrooms, saunas, baths, because moisture-resistant adhesives can withstand even direct contact with water.

to contents ↑Advantages and disadvantages

The main advantages of Eunice adhesive mixtures are their strength and excellent adhesion. Glues give good adhesion to any substrates, serve for a long time, which greatly facilitates the repair and subsequent operation of the coating. The glue line retains its properties at low and high temperatures, but only those formulations that are frost-resistant can withstand freezing. Among the Eunice products there are products that even the conditions of the North endure.

Other advantages of brand adhesives:

- environmental safety, the absence of toxic secretions and unpleasant odors;

- ease of applying the composition - there is no need for special knowledge;

- parallel gluing of tiles and leveling the base;

- excellent resistance to sliding tiles even on vertical and inclined surfaces;

- suitability for all types of tiles - from the smallest mosaic to plates with a size of 60 * 60 cm and more;

- low consumption per 1 m2 (varies depending on the specific type of glue);

- a large mortar life cycle - the tiler will probably have time to lay down a sufficient number of elements, as well as adjust their position;

- resistance to high humidity;

- the ability to use in underfloor heating systems.

The disadvantages of Eunice solutions are few. Most adhesives have a gray color, so it is impossible to use them for gluing transparent or translucent tiles. Classical compounds cannot stick a stone weighing more than 100 kg / sq. m. To perform high-quality and durable finish, you will have to carefully prepare the base, and this will take a lot of time, and sometimes additional materials.

to contents ↑The maximum size of defects for standard tile adhesives should not exceed 5-7 mm in depth, otherwise you will have to level the surface first (there are compositions with a higher leveling ability). At minus temperatures it is impossible to work with adhesives, although after drying they can be used in harsh conditions.

Types of adhesive mixtures from Eunice and technical specifications

The most popular adhesives in the Unis line are Eunice Plus and Eunice 2000. The company also produces specialized compounds and progressive adhesives made using the most modern technologies. All adhesives are packaged in packages of 5 and 25 kg. It is important to store any mixture correctly: leave it only in a dry room, and on a wooden pallet so that it does not become damp. Shelf life under proper conditions is 12 months.

to contents ↑Eunice Plus

The composition of Unis Plus in red packaging is familiar to all professional tilers. It is suitable for all types of tiles - ordinary, porcelain stoneware, mosaics, stone, while being positioned as adhesive for complex substrates. The manufacturer advises using the product when decorating the facade with porcelain tiles, laying tiles on tiles, installing a warm floor. There are limitations in operation only when finishing the base and deformable substrates, for this purpose it is better to choose a specialized composition.

The strength of the glue is very high - 1.25 MPa, it easily withstands the load of tiles weighing more than 100 kg per square meter. Other technical parameters of Eunice Plus:

- approximate consumption - 3.5-4.5 kg / sq. m;

- compressive strength - 7.5 MPa;

- the life cycle of the solution is 3 hours;

- time for laying tiles after applying the solution - 20 minutes;

- tile correction time - 10 minutes;

- frost resistance - 35 cycles;

- the period to complete solidification - 24 hours;

- layer thickness - 3-15 mm.

to contents ↑5-5.5 l of water is consumed per bag of 25 kg, that is, the ratio of dry powder to liquid is approximately 5: 1. The finished coating can be operated at temperatures of -35 ... + 70 degrees.

Eunice 2000

This is another well-known composition from Unis in black packaging. This tile adhesive is designed for exterior and interior use, is highly durable, glues and evens height differences up to 15 mm. Due to the excellent adhesive ability, the product can be used not only for standard tiles, but also for porcelain stoneware, stone up to 60 * 60 cm in size. Unis 2000 can be used on strong, non-deformable substrates when finishing floors, walls inside and outside buildings, but only on unheated surfaces. Also, the scope of application of the adhesive extends to:

- building facades above the basement;

- rooms with high humidity;

- balconies and terraces.

Unis 2000 differs from the previous product in the reduced working time of the mortar after it has been applied to the surface: you need to lay the tile in 10, not 20 minutes. The viability of the solution is also less - 2 hours, and the retained weight of the tile per 1 square meter of area - up to 80 kg. Adhesive adhesion is also below 1 MPa.This tile adhesive allows you to use it in more severe conditions, it does not deteriorate from operation at temperatures of -50 ... + 50 degrees.

to contents ↑Eunice 21

Economic moisture-resistant glue of this variety is intended for finishing with tiles in the bathroom and kitchen, it is suitable for floors, walls, and it is not used for porcelain tiles and slabs larger than 30 * 30 cm. In addition to damp rooms, the tool is also useful for freezing rooms. Unis 21 is produced in two varieties - only for internal work or for external and internal work. The difference between them is in terms of adhesion (0.5 and 0.7 MPa) and the limiting thickness of the adhesive layer (10 and 15 mm).

Technical parameters are as follows:

- average consumption - 3.5 kg / sq. m;

- the life of the solution is 3 hours;

- adjustment time - 10 minutes;

- period before operation - 24 hours;

- frost resistance - 35 cycles;

- maximum load per square meter of glue - 40 kg.

to contents ↑The finished coating can be operated at temperatures of -50 ... + 50 degrees, although freezing can be allowed only after a month from the moment of applying the adhesive layer. Eunice 21 withstands high humidity, but does not tolerate constant contact with water.

Eunice HiTech

This glue is used for finishing complex substrates. To create it, new technologies are used to improve the quality of adhesion to the tiles. Using glue, tile coatings can be mounted not only on vertical bases and on the floor, but also on ceiling surfaces and ceilings. It is permissible to lay the tiles by the method from top to bottom.

The characteristics of the tool are as follows:

- layer thickness - 3-15 mm;

- approximate consumption per square meter - 3.5 kg;

- frost resistance - up to 35 cycles;

- the held weight is 50 kg / sq. m

The viability of the solution is seriously increased - it is 300 minutes, the adjustment also increased to 15 minutes, and the working time after applying the solution is 25 minutes. You can use the coating after a day, as is the case with other brand adhesives.

to contents ↑Eunice Granite

The glue is characterized by ultra-strong fixation and is intended for large plates, massive elements made of stone and porcelain. “Eunice Granite” is used even for tiles larger than 60 * 60 cm, it allows finishing socles and facades, walls and floors, various complex bases. The adhesion level of the composition is very high - 1.5 MPa, which is much higher than that of analogues, and allows you to lay new tiles even on the old.

Eunice Granite has a low consumption - up to 3.5 kg per square meter, which is associated with the small recommended layer thickness (3-10 mm). The finished portion of the solution does not deteriorate within 3 hours, and you can adjust the position of the tile in 10 minutes. Before starting walking on the tile, 24 hours should pass, and only then can it be fully exploited. Glue frost resistance - 35 cycles.

to contents ↑Eunice Belfix

White tile adhesive of the Eunice Belfix brand is intended for light mosaics, porcelain stoneware and glass mosaics. It provides reliable fixation and filling of joints, guarantees increased frost resistance - up to 75 cycles. Typically, Belfix is used when a standard gray mixture is not suitable. The tool is highly elastic, resistant to negative temperatures. It can also be used for grouting.

The characteristics of Belfix are as follows:

- operating temperatures - -50 ... + 70 degrees;

- time to operation - 24 hours;

- layer thickness - up to 10 mm;

- readiness of the solution for work - 3 hours;

- adjustment time - 15 minutes.

to contents ↑Using glue, you can finish water tanks, walls and floors in rooms with high humidity. It is suitable for outdoor and indoor use.

Unis fix

This composition for tiles and mosaic tiles has an average level of adhesion (0.5 MPa), but it is cheaper than other Unis brand products. Glue is intended for facing uneven surfaces, bases in the kitchen, bathroom, on balconies and terraces.It is permissible to apply glue with a layer of 3-15 mm, and it is desirable that the indicator be close to the upper boundary (due to this, the consumption increases to 5 kg per square meter). Other technical parameters:

- the life of the solution is 180 minutes;

- adjustment time - 10 minutes;

- working time of the solution after application - 10 minutes;

- the period before operation - a day;

- frost resistance - 75 cycles;

- operating temperatures - -50 ... + 70 degrees.

Eunice Pool

Glue "Eunice Pool" is used to fix the tiles, mosaic, ceramic and stone tiles in the exterior and interior. It perfectly sticks the coating even on complex substrates, in freezing rooms, in pools and other water tanks. The tool is suitable for finishing a warm floor, laying new tiles on the previous one. It is important to observe the restriction on the size of the elements: you can not work with glue "Eunice Pool" with tiles over 60 * 60 cm.

Adhesive consumption usually does not exceed 3.1 kg / sq. m, because it is applied with a layer of 3-6 mm, no more. The standard tile correction time is 10 minutes, as well as the period before the surface begins to operate - 24 hours. The adhesion of the composition is 0.5 MPa, the retained weight of the tile is 60 kg per square meter. Frost resistance - 35 cycles.

to contents ↑Teplokley

Glue and plaster mix for thermal insulation systems is used outside and inside the premises, it is intended for reinforcing various substrates and the installation of an insulating layer of expanded polystyrene, glass wool, mineral wool. With the help of Teplokley, marble, tiles, ceramics, and tiles can be firmly fixed, it is also suitable for facing stoves, fireplaces. To protect the bases from fungus, in parallel it is recommended to use a primer of the Unis brand.

Glue is used for manual and machine application. It has excellent elasticity and is therefore suitable even for deformable substrates. The glue does not interfere with gas exchange and can be used in arranging breathable coatings. The main characteristics are as follows:

- layer thickness - 2-15 mm;

- consumption - 3.5-4.5 kg per square meter;

- frost resistance - 75 cycles;

- adhesion - 1 MPa;

- open time - 20 minutes;

- water absorption - 5%;

- vapor permeability - 0.1 mg / m * h * Pa;

- operating temperatures - -50 ... + 100 degrees.

You can use Eunice Teplokley for almost any type of thermal insulation with different absorbency, weight, and density, which is due to the large adhesion to the bases. It is especially recommended to buy glue for fixing fibrous thermal insulation, which has increased vapor permeability. The finished solution is plastic, easy to use, does not emit harmful substances when heated.

to contents ↑Eunice Horizon

"Horizon" from "Eunice" - a means for pouring floors, because it is often called "liquid linoleum." After dilution and application, a seamless coating is created that can even out height differences of up to 100 mm. Glue is used for manual, machine leveling of floors, screeds, can be used on load-bearing substrates. "Horizon" is suitable for thick-layer and thin-layer leveling, warm and floating floor systems. Suitable for non-freezing, heated rooms with any humidity.

Adhesive Characteristics:

- layer thickness - 2-100 mm;

- filler fraction - up to 1 mm;

- consumption with a minimum thickness of up to 3 kg / sq. m;

- the viability of the solution is 0.5 hours;

- time before the start of walking - 3 hours;

- time of complete drying of the layer 1 cm thick - 3-7 days;

- compressive strength - 150 kg / sq. cm.

Due to the short time to walking, Eunice Horizon is used to equip the finish coat or screed in one application, which seriously speeds up the repair process.

to contents ↑Rapido

The modern adhesive composition Rapido is designed for different types of tiles up to 60 * 60 cm in size, which can be laid on the floor, walls in wet, dry, unheated and heated rooms. The glue is also suitable for outdoor work, usually with its help produce cladding of buildings. A high degree of adhesion (1 MPa) allows Rapido to be used on such surfaces:

- entrance groups to buildings;

- landings and marches;

- industrial workshops;

- Warehouses

- socles.

You can lay tiles, porcelain tiles with glue even in underfloor heating systems and on an old foundation. Its parameters:

- frost resistance - 100 cycles;

- operating temperatures - -40 ... + 70 degrees;

- adjustment time - 10 minutes;

- layer thickness - 2-10 mm;

- consumption per layer of 1 mm - 1.45-1.55 kg / square meter;

- the life of the solution is 40 minutes;

- the possibility of walking on the coating - after 3 hours;

- compressive strength - 7.5 MPa.

U 100

U 100 highly elastic adhesive is suitable for different types of tiles - ceramics, clinker, porcelain stoneware, stone, and for any format. The tool is suitable for external and internal work on deformable, non-deformable bases:

- cement, gypsum plasters;

- screeds;

- concrete over 2 months old;

- cellular concrete;

- gas silicate;

- GKL, GWP, GVL;

- cement chipboards;

- OSB;

- painted surfaces.

to contents ↑Glue can withstand the largest loads, therefore it is widely used for decoration of industrial, administrative, commercial premises, parking lots and stairs, train stations and airports. The composition is suitable for the installation of underfloor heating, facing stoves, fireplaces. The adhesion level of U 100 is very high - 1.8 MPa, the adhesive easily withstands operation at temperatures of -60 ... + 120 degrees. Tile adjustment time is seriously increased and amounts to 1 hour, the frost resistance of the adhesive is 100 cycles.

Maxiflex

Maxiflex glue is a novelty among Unis products. This superelastic adhesive is specifically designed for deformable and complex substrates, including young concrete and wood-based panels. Using glue, it is possible to finish socles, steps and platforms of stairs, rooms subject to the highest loads (including metro stations).

Unlike other glues of the line, Maxiflex is packaged in packages of 20 kg. Its consumption is small - from 1.25 kg / square meter, it can withstand 100 cycles of freezing and thawing. The recommended layer thickness is less than 1 cm. You can operate the finished coating at temperatures of -40 ... + 100 degrees. The degree of adhesion with the base is high - 1.8 MPa.

to contents ↑Super Plus

Glue of this type is used for any non-deforming and deforming substrates. With it, you can finish all types of surface tiles, subject to high loads. The maximum size of porcelain stoneware that can be glued to Super Plus without additional mechanical fastening is 70 * 70 cm. Technical parameters are as follows:

- adhesion - 1.3 MPa;

- tile laying and adjustment time - 20 minutes;

- layer thickness - 2-25 mm;

- the viability of the solution is 3 hours;

- time to surface operation - 24 hours;

- frost resistance - 100 cycles;

- operating temperatures - -40 ... + 80 degrees.

Flow calculator

Usually, all work with glue is carried out using a notched trowel, because Unis brand products do not require continuous application. The teeth leave empty furrows, therefore, glue consumption is reduced. So that it does not rise, it is better to process too uneven bases with plaster first.

The working layer should not exceed 15 mm, its minimum thickness is 2-3 mm. Usually, in the presence of a spatula with teeth 6.2 * 6.2 cm in size, the consumption varies from 3.5 to 4.8 kg with the largest thickness of the seam. A spatula, the teeth of which measure 3.1 * 3.1 cm, "picks up" less glue - up to 3.5 kg. Do not violate the proportions - dilute the adhesive with water should be strictly according to the instructions for use. Otherwise, the flow rate may change upwards. The preparation of too large portions of the solution also negatively affects the economy: if you do not have time to use up the glue, it will deteriorate.

to contents ↑General instructions for use

Work with any glue of the Unis line is allowed at humidity less than 75%, temperature + 5 ... + 30 degrees.

Surface preparation

Before starting work, you need to carefully prepare the base. You should remove the old finish, align the wall or floor, leaving differences of not more than 1-10 mm (depending on the type of mixture). If the defects are deep, they need to be leveled with plaster. The old tile can not be removed, but to improve adhesion, notches should be made every 5 cm in a checkerboard pattern. You also need to do the following:

- degrease the base;

- completely dry the surface;

- moist rooms, basements treated with waterproofing (you can choose a product brand "Eunice");

- apply a primer 1-2 times;

- dry the base again (how long the soil dries depends on its type).

Solution mixing

Glue should be diluted only in a clean container, with a clean tool. Pour the dry mixture into a container with water in the proportion indicated on the package. The solution is mixed for 5 minutes using a construction mixer. Leave the glue for 5 minutes, then mix it again. If the instructions are not followed, the properties of the composition deteriorate.

Glue application

The prepared solution is applied to the prepared base with a notched trowel, having previously taken it with a trowel. A layer of the required thickness is made, leveled with trowel teeth. Instead of the latter, a comb grater can also be used. Then lay the tile, firmly pressed. The glue should be distributed evenly, there should be no voids under the tiles. It is permissible to tap the tile with a wooden or rubber mallet, squeeze in wavy movements.

If work is carried out outside the premises, glue is additionally applied to the tiles themselves. Do the same with large items. After laying, there is little time left for adjusting the tiles. To maintain uniform seams put crosses. After a day, you can start trowelling. Heated floor is mounted after 28 days.

Tile adhesive brand "Eunice" - one of the most reliable. Choosing it for laying tiles, you can not worry about the aesthetic appearance and high quality finish, which will last for many years.