It sounds paradoxical, but it’s actually so: to save money, you must first invest money. This statement is also true for repair work. And where does any decoration begin? With a primer. It depends on it the consumption of finishing materials, their adhesion to the base. One of the best among primers is considered a polyurethane primer.

- Advantages and disadvantages of polyurethane-based primers

- Varieties of primers

- What to look for when choosing

- How to apply to the surface

Advantages and disadvantages of polyurethane-based primers

When using a primer based on polyurethane, the following advantages can be obtained:

- Processing of the bases with any absorbing ability and made of any material (wood, concrete or metal) is possible.

- Processing of bases not previously cleared of dust is allowed, the components of polyurethane will bind the dust and well strengthen the structure of the base.

- It is possible to apply to the floor with working underfloor heating. This is only permissible for a polyurethane compound - other mixtures will cause harm to the floor.

- Universality. It can be used both for outdoor work and for interior decoration.

- Low consumption (0.2-0.5 kg per 1 m2 of surface depending on the penetration depth), while for most primers this figure is 0.8-1.0 kg per 1 m2.

- Subsequent restoration work will not be required soon due to the fact that the soil-mixture is durable, reliably protects and strengthens the treated surfaces.

Among the shortcomings can be noted:

- Low drying speed (about 3-5 hours), while for most soil compositions the drying time does not exceed 2 hours.

- Pretty high price. However, it is worth noting that the soil based on polyurethane is very durable and subsequent repairs will not be needed soon.

Varieties of primers

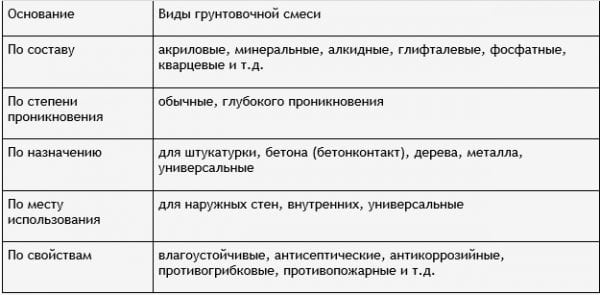

The primer mixture consists of polyurethane and various solvents, but depending on the material of the primed base and its location, the primers may vary in composition due to special additives that give them additional properties. According to the degree of curing, there are:

- One-component, consisting of a solvent and a basic substance. A one-component polyurethane primer is often used for interior work on MDF or wood, not bad for concrete walls. Its fluid structure penetrates deep into the MDF slab or concrete wall, strengthening and leveling the base, increasing adhesion for applying the finish coating.

- Two-component, produced in the form of two bottles (polyurethane mixture and hardener), which are mixed before use. The two-component polyurethane primer is more durable, but less fluid due to the presence of a hardener, well suited for outdoor use or for concrete floors with high traffic. If the solution contains a zinc-filled component, this will provide corrosion protection to the metal. For wood or MDF is rarely used. Often, when priming is the only method of painting, for example, when protecting the floor in a workshop or garage, it is worth using enamel primer, which will strengthen the concrete structure, protect it from destruction.

By type of primer mixes are:

- Acrylic, as a rule, one-component. More suitable for MDF and wood. They penetrate deeply, filling free pores, and leveling the surface. This quality is especially important when non-laminated MDF is processed. Acrylic solutions give good results on concrete walls indoors, strengthening and leveling them. In addition, the acrylic component is non-toxic.

- Alkyd. It is good to apply when carrying out outdoor works for MDF and wood, providing the wooden structure with reliable protection against darkening and damage. If you want to emphasize the beauty of a wooden surface, then it is worth using primer-enamel, which will become both a primer and a finish coat. Soil-enamels, as a rule, are used to emphasize the beauty of various types of wood, MDF is rarely painted with them.

- Epoxy They are best suited for the metal, providing its protection against external conditions, and if there is an additional zinc-filled component, then this will give the solution anti-rust properties. But it should be remembered that zinc-coated soils do not adhere well to the decorative coating - it is advisable to treat them with a adhesion-enhancing agent after drying, or use enamel primers for painting metal.

What to look for when choosing

Despite the fact that the polyurethane primer is universal and suitable for almost all types of substrates, it is advisable to take into account the following when choosing it:

- The location of the processed object. The important thing is whether it is located inside or on the street, what temperature changes it is exposed to, the level of humidity. At high loads on the object, it is desirable to use two-component soils.

- The material of the primed base. After all, those soil mixtures that are well suited for MDF or concrete, very poorly fit on the metal.

- Environmental friendliness. For residential premises, you need to choose non-toxic drugs, preferably from polyurethane with acrylic. They are well suited for wood and concrete, and of these materials most often make the floor and walls of living rooms.

How to apply to the surface

The method of applying primers with polyurethane is simple, it is almost no different from applying other primers, only its structure is not suitable for using a spray gun. You can apply the solution:

- Rollers of various sizes. They can quickly and evenly paint a large area.

- Tassels. It is better to use them as an auxiliary tool for painting hard-to-reach spots - their processing of large areas takes a lot of time.

The soil-mixture is allowed to be applied on an unpurified surface, but for a better “setting" the treated area is desirable:

- clean from dust and the remnants of the old finish;

- to wash;

- dry and degrease;

- close up large cracks, small ones can be left - the polymer mixture will evenly fill them, leveling the surface.

After such preparation, you can primer:

- The solution is evenly distributed over the entire area using a roller.

- After complete drying (after 3-5 hours), a second coat can be applied. It should be remembered that you need to work crosswise, that is, if during the first priming the direction of movement was vertical, then when applying the second layer, the roller should move in the horizontal direction, this will ensure the most uniform impregnation. A third layer, as a rule, is not required, and after drying, you can proceed to the decorative finish.

Primer composition with polyurethane is easy to use, durable in use, provides reinforcement of the base and full protection of the material. Having spent on the purchase of primers based on polyurethane during repairs, you can save a lot in the future by postponing the necessary repair work for a long time.