Modern polymeric materials have become the basis for various building compounds that make structures stronger, more reliable and more durable, are multifunctional. A striking example is polyurethane sealant: this product is suitable for external and internal use, it can close joints, stop leaks and even repair concrete buildings and roofs.

- What is polyurethane sealant

- Properties and characteristics

- Sealant Types

- One component

- Two-component

- Sealants for concrete

- Roofing

- Sealant Consumption

- Sealant Colors

- Application area

- Dissolution and Dilution

- Advantages and disadvantages

- Sealant Instructions

- Manufacturers

- "Moment"

- Izhora

- Olin

- Retel car

- Sikaflex

- Dap

What is polyurethane sealant

These are visco-elastic polymeric materials based on urethane resins - synthetic elastomers. They belong to a new generation of sealing compounds and in many industries have replaced natural and artificial rubber sealants.

Polyurethane was first obtained in Germany by combining polyols with diisocyanates. The new synthetic substance soon became the base when creating a number of construction and assembly compounds. Now polyurethane sealants are considered the most popular and demanded in the whole world, they are sold everywhere and are used for roof repair, tile laying and other purposes.

to contents ↑

Properties and characteristics

When applied to the surface, polyurethane adhesive sealant performs two important functions. It firmly glues the products together and reliably seals the joints between the surfaces.

Polyurethane occupies the bulk of the material, so the product has a high degree of elasticity (up to 99.9%). It is easy to apply sealant, it evenly lays on any foundation, does not crack from deformation and mechanical stress.

Polyurethane sealants harden quickly, they must be handled with sufficient skill. After curing, the seam can be painted in any color, although there are transparent options on sale that are almost invisible on products.

The main properties of the sealant and its technical characteristics are as follows:

- frost resistance up to –60 degrees;

- high adhesion with metal, concrete, plastic, ceramics and a number of other materials;

- moisture resistance;

- Shore hardness (indentation method) - 15-50 units;

- high tensile strength;

- resistance to vibration, chemicals, ultraviolet;

- density - 1200-1500 kg / cubic m;

- lack of shrinkage.

to contents ↑It is necessary to store the polyurethane-based sealant in a cool place, the shelf life is about 10-12 months. It is sold in tubes of 300-370 ml, as well as in larger bottles, cartridges, buckets, soft packs (from 600 ml).

Sealant Types

Among the polyurethane sealants, one and two-component products can be distinguished, as well as special compositions for concrete and roofing.

One component

This type of sealant is considered the most popular because it is ready for use, does not require mixing of components or dilution. The consistency of the product resembles a paste, rather viscous, after application requires leveling.For example, the TechnoNIKOL polyurethane sealant is an elastic mass with high adhesion and excellent ductility.

One-component sealants harden when exposed to moisture from the air. The quality of the joints is consistently high, including when sealing the most complex and capricious materials (for example, glass, ceramics).

This allows the use of similar compositions for gluing automotive optics, glasses, as well as for joining dissimilar materials. One-component products are suitable for vertical and horizontal expansion joints, some are even used in roof repairs.

Most polyurethane sealants from this group are not suitable for use at temperatures below –10 ... –15 degrees. They begin to lose elasticity, adhesion and hardness, resulting in a reduced service life of the seam. For outdoor use, it is worth buying two-pack compositions that have improved adhesion and frost resistance.

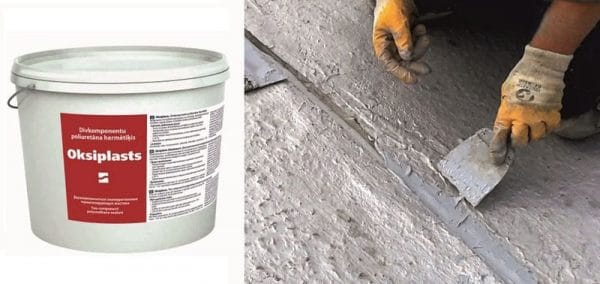

to contents ↑Two-component

The difference between these sealants from single-component ones is in the number of packages: the products are paste (base) and hardener, which must be mixed together immediately before work. While the components are not connected, they can be stored for a long time, but as they mix, they require rapid application to the base, since they soon undergo polymerization.

Two-component compositions are more durable, withstand significant temperature differences, are highly moisture resistant. Seams can be frozen many times, and still remain elastic and do not crumble. Cons of such funds are also available:

- it is necessary to observe the exact proportions of the components, otherwise the properties of the sealing composition will deteriorate;

- mixing will require additional time, tools;

- if sealant is not applied immediately after mixing, polymerization will begin and the mass will become unusable.

to contents ↑Usually, two-component compositions are used by professionals, and for household needs a one-component polyurethane sealant is better.

Sealants for concrete

Such products are specialized formulations based on polyurethane, which are intended for concrete work. They do not have aggressive components that could harm the mineral material. Most often, sealing compounds are used for outdoor work, they are implemented in finished form or are two-component. Polyurethane concrete sealants are ideal for sealing cracks, gaps or defects that appear over time.

to contents ↑Roofing

Roofing sealants include acrylic, silicone, bitumen and polyurethane compounds. The latter, in addition to polyurethane, include other resins that give the mass special ductility, smoothness and adhesion to metal, and other roofing materials. All products have both sealing and waterproofing ability, perfectly withstand direct contact with water, do not spoil from frost and ultraviolet radiation.

to contents ↑Sealant Consumption

Polyurethane products are very economical in consumption. To calculate the amount of material required, you need to know the depth of the seam and its width. When these numbers are multiplied, the amount of sealant in milliliters per 1 linear meter of a square or rectangular seam will be obtained. If you plan to make a triangular seam, the figure should be divided in two.

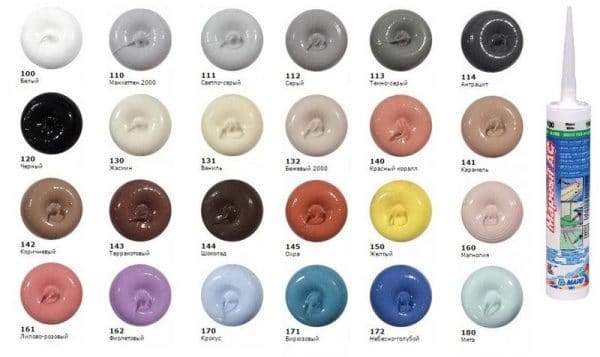

Sealant Colors

Color schemes can be very diverse. There are white and transparent products on sale, as well as matte sealants in black, gray, brown, beige. Some brands produce colored sealants - red, yellow, green and others. The shade is chosen depending on the main tone of the product, so that the seam is as invisible as possible.

to contents ↑Application area

The scope of use of polyurethane compounds is extensive. They can close up joints, glue products, materials and individual elements, seal joints from leaks and protect them from water and air.Most often, polyurethane is used in the following areas:

- installation of windows, doors;

- processing of interpanel joints, facades;

- work with artificial and natural stone;

- installation of products subject to strong vibration, deformation, shrinkage;

- repair of various car components;

- the device is heated and exposed to freezing joints;

- laying or restoration of the roof, its individual elements;

- creation of reservoirs, fountains;

- sealing pipes, plumbing, tiles in the bathroom;

- work with timber, other types of lumber;

- installation of glass structures, concrete floors, metal products;

- different types of work in shipbuilding.

to contents ↑

Dissolution and Dilution

It happens that the sealant was applied sloppy, and spots or excesses appeared on the surface. It is difficult to wipe off the frozen substance, and polymerization occurs rather quickly. It is necessary to soften the polyurethane, for which alkaline compounds are used. Large layers of sealant should first be cut with a sharp knife. Special polyurethane removers are also available (e.g. AcesolvePUN). Usually they are used by professionals to clean equipment and tools.

If a one-component sealant has thickened, it can be diluted with an organic solvent. Xylene and solvent 646 are best suited for this purpose. Many similar compounds cannot be introduced into the sealant - it can lose its properties, become too liquid and inelastic, not strong enough. The maximum amount of solvent is 5-10%. If the sealant is thick, it is better to buy a new package and use it to work.

to contents ↑Advantages and disadvantages

Polyurethane sealants have a huge number of advantages, and the main one is excellent elasticity, which does not allow the material to crumble, crack, deteriorate from shrinkage of the base. Other advantages of sealants:

- high adhesion with most known materials;

- wear resistance, moisture resistance, tolerance of contacts with chemicals and UV rays;

- excellent sealing and waterproofing;

- lack of corrosion in places of drawing on metal;

- trouble-free operation at low and high temperatures, temperature and humidity differences;

- the ability to apply at any time of the year;

- lack of sagging during application;

- seams of any thickness;

- shrinking;

- drying in a short time;

- long operation.

Cons of such sealants are also available. Some formulations withstand heat up to a maximum of +100 degrees, as there is a mark on the package. If the product is based on organic solvents, it is toxic to humans (only before drying), and you must work with it with strict observance of personal protective measures. When bonding some types of plastics, adhesion to the substrate may be insufficient. On materials such as on surfaces with a humidity above 10%, first apply a layer of special primer, and only then apply sealant.

to contents ↑Sealant Instructions

Before sealing, all bases must be properly prepared. To do this, work surfaces are cleaned of contaminants. Remove all dust deposits, oil stains and drips, old paint and other paints and varnishes. The rust is removed with sandpaper, using sandblasting or a grinding machine. Interpanel, interblock seams are first insulated. To this end, purchase mounting foam or foamed polyethylene.

They work with sealant in the open air only in clear, dry weather, when there is no rain or other precipitation. It is advisable to use the product at positive temperatures, although some of them allow the possibility of application at –5 ... –10 degrees.Polyurethane sealant is applied over insulation materials without special treatment. If we are talking about deformable panel joints, it is better to choose a two-component composition that can withstand a shift of 10-12% or more.

Sealants, including paste and hardener, are mixed in the proportions specified by the manufacturer. Mixing is best done with a power tool (drill with a special nozzle), or manually for 10 minutes until an absolutely homogeneous consistency is obtained.

Before work, cut off the tip from the nozzle of the cartridge, install the latter in the gun. The cut diameter is made about 2 times larger than the width of the hole so that the seam reliably covers the defect, joint, gap.

To work with polyurethane sealants, the following types of guns are used:

- Mechanical. Assume manual trigger pull and adjustment of thickness, seam length. Suitable for a small amount of work, household needs.

- Pneumatic Use the force of air flow. Used by professionals, ideal for medium-sized jobs.

- Rechargeable. Well suited for sealing interpanel joints in multi-story buildings, for significant actions.

Sealants in the form of "sausage" or means from buckets, as well as two-component compositions, are poured into special pistols with containers or applied with a spatula. The sealing layer should be even, not include voids, tears. After application, the seam is leveled with a wet spatula. Drying time is usually 3 hours, but some products are not recommended to be put into operation within 24 hours.

to contents ↑Manufacturers

The stores present sealants based on well-known brands of polyurethane, which you can buy without regard to quality.

"Moment"

The “Moment-Germent” line includes several types of polyurethane sealants, which are very popular among manufacturers. All products have a long service life, are resistant to chemicals, ultraviolet radiation, demonstrate excellent elasticity and adhesion to different surfaces. Sealants are suitable for work in the bathroom, for roofing, installation of roof tiles and skates, insulation of various building materials.

to contents ↑Izhora

They are one-and two-component, they can be used for repair work, sealing joints on socles, facades, for processing joints and cracks on ceilings, mounting doors, windows. The latest technologies are widely used for the production of sealants, therefore, the adhesion and elasticity of all products are maximum in value.

to contents ↑Olin

Compounds under this name are made in France. The manufacturer's assortment includes Isoseal P40 and P25 sealants, which are excellent for glass, metals, wood, ceramics, concrete. They are sold in cartridges of 300 and 600 ml and have various shades (including bright ones).

to contents ↑Retel car

Italian polyurethane-based sealants are suitable even for inclined and vertical substrates; they do not leak due to their density. Funds are suitable for sealing containers, body repair, ventilation, air conditioning systems.

to contents ↑Sikaflex

High-quality sealants of this brand are considered universal, multi-purpose in purpose. They are ideal for roofing, installation of automotive systems, concrete work, gluing finishes, for various household purposes. Means well grasp even with plastics and glass.

to contents ↑Dap

Sealants from the USA based on polyurethane have excellent quality indicators at a reasonable price. Most often they are used for domestic needs, for example, for closing joints in the bathroom and in the kitchen. The compositions have good elasticity and adhesion to any surfaces.

The use of polyurethane sealants significantly extends the life of many products and structures. Such tools help to reduce the risk of leaks and tightly fasten the parts, so they are recommended for home and professional use.