External compaction of the structure is a very responsible task. It allows you to achieve excellent results, ranging from reducing heat loss in the rooms and ending with protection against mold.

- Sealant requirements for outdoor applications

- Features

- Kinds and advantages

- Silicone

- Acrylic

- Polyurethane

- Rubber

- Bituminous

- Scope of application

- Application technology

- Consumption

- Tips & Tricks

But it is worth considering that not all materials have a wide range of operating temperatures, and if this factor is not taken into account, then sealing and sealing will not lead to the desired result. A frost-resistant and waterproof sealant for outdoor works, which can be easily found in construction stores and in the market, helps to fix the situation.

to contents ↑Sealant requirements for outdoor applications

Special requirements are imposed on such compositions, which can be explained by harsh operating conditions. The main thing - they must be resistant to ultraviolet radiation. It is very detrimental to various materials, as a result of which they lose their quality and are deformed.

Severe frosts and seasonal temperature drops provide no less threat to buildings. That is why sealants with a wide temperature range should be used. It should be borne in mind that in addition to resistance to frost and dampness, such compositions should be insensitive to strong heat, not crack or dry, while maintaining high adhesion and elasticity.

to contents ↑There is another requirement - durability. Since external sealing of butt joints is a laborious and very expensive procedure, it is recommended to use materials designed for 15–20 years of service.

Features

Many people are interested in what advantages sealants have for external use and why they are so useful compared to conventional formulations. All thanks to the following features:

- Good elasticity. A very important property, since it allows you to fill all cracks and cracks and at the same time hold the seal inside the cavity.

- High strength. This feature is necessary for those objects that are constantly exposed to external factors leading to shifts and displacements. For example, it can be both increased vibration and seismic activity.

- Resistance to sharp changes in ambient temperature. This is one of the key properties of external sealants, because otherwise the sealant will lose its features.

- Excellent adhesion. These compounds perfectly adhere to different surfaces, not only rough but also smooth, which greatly simplifies the work with them.

Another important advantage is frost resistance. Such sealants are perfect for harsh domestic climates, since they do not lose the above properties even at –35 ... –60 degrees Celsius (depending on the manufacturer).

It should be noted that modern sealants are excellent for sealing a wide variety of materials, including:

- masonry;

- concrete blocks;

- wooden buildings.

Thanks to this, frost-resistant sealant has been widely used both in large and low-rise construction.

to contents ↑Kinds and advantages

Today on sale you can find a variety of compositions, and each of them has both advantages and disadvantages. Just note that the price segment of this product is very wide, so you can easily find a tool at an affordable cost.

There are 5 main types of frost-resistant sealants that deserve attention. We will consider them further.

Silicone

One of the most common means. It is considered universal and is great for outdoor work when you need to seal the docking slots.

Silicone sealants allow you to create an elastic seam that has:

- wide range of operating temperatures;

- resistance to moisture, water and dampness;

- excellent adhesion (except for porous materials, including plaster and concrete).

Some sealants of this type have an unpleasant sour smell, which is formed due to the release of acetic acid vapor during curing. However, neutral formulations can also be found on sale.

to contents ↑When choosing sealants of this type, keep in mind that they are not suitable for painting, and also do not support restoration of the seam (during deformation, you will need to remove it and apply the agent again).

Acrylic

These compounds are considered the most environmentally friendly, because they do not contain harmful substances. Due to this, they are suitable for sealing private buildings. In addition, they are known for good vapor permeability, which differs from other means.

Acrylic compounds are suitable for the treatment of wooden structures. With their help, you can close the joints between the timber or log, providing excellent insulation from negative environmental factors. Among the other advantages of acrylic sealants it is worth highlighting:

- simplicity of operation;

- versatility, because due to the high adhesion, these compounds adhere well on both smooth and porous surfaces, including stone, metal, concrete, glass and others;

- resistance to UV radiation;

- the possibility of partial or complete restoration of the seam;

- fire safety.

These compounds are cheap and affordable. When buying, it is recommended that you read the instructions on the package and make sure that the sealant is frost-resistant (there must be an appropriate mark).

to contents ↑Polyurethane

Despite the fact that this type appeared on the market not so long ago, its popularity is growing rapidly. Besides good waterproof properties and high elasticity, these sealants are known for their excellent resistance to frost. They withstand temperatures up to –60 degrees Celsius and keep the seam as tight and undamaged as possible.

Means of this type are characterized by slight shrinkage after polymerization. They are resistant to direct sunlight. Their curing occurs upon contact with atmospheric moisture. If we are talking about two-component sealants, then the polymerization proceeds by mixing the substances that make up the composition.

Curious is the service life of polyurethane products. It reaches 20 years, and at the same time, the seam does not require updating (with the exception of mechanical or any other damage). As for the scope, these compounds are suitable for sealing:

- foundation;

- roofing;

- interpanel seams;

- window and doorways.

Rubber

These sealants are known for their unusual composition, which in addition to elastomers and oligomers may include:

- bitumen;

- solvents;

- resins;

- various fibers.

Due to this, the consistency of these sealants is very similar to ordinary rubber. Rubber based products are known for their strongest adhesion. They adhere perfectly to both wood and stone, making them suitable for a wide range of jobs.

These compounds withstand frosts up to –50 degrees Celsius and at the same time protect materials from the formation of corrosive processes, making them very famous in the professional field.They are not afraid of either water or ultraviolet radiation, and after polymerization, the sealing joint can be coated with paint. This type of sealant is applied even on a damp surface, without fear of reducing adhesion.

to contents ↑Bituminous

Bituminous sealant is mainly intended for roofing. It allows you to eliminate damage to both rolled materials and corrugated board, while preventing moisture from entering the subroofing space.

Of the advantages of these compounds, we can distinguish:

- ease of application;

- good adhesion to metal surfaces;

- lack of need for preliminary preparation;

- quick cure.

to contents ↑Due to the listed properties, bitumen sealants are suitable even for waterproofing foundations and drainage systems. They are known for high resistance to frost and prevent the formation of mold and the spread of fungi, which is especially important for residential buildings.

Scope of application

These funds are used to prepare the building for the cold season. Despite the fact that some of them are used in a humid environment, it is recommended to use them in dry weather, which will help to achieve an excellent result.

Frost-resistant sealants are suitable for processing:

- residential multi-apartment buildings;

- private low-rise cottages;

- shopping and business centers;

- storage facilities;

- hangars;

- production shops;

- communal facilities;

- engineering systems.

Most often they are used to seal interpanel seams and window openings, which helps to prevent drafts. They are indispensable for roofing or for waterproofing concrete structures. Considering good adhesion, frost-resistant sealants are suitable for buildings of any materials.

With the help of these compounds, it is possible to easily fill small voids, and the seam will help not only close them, but also tighten the edges, preventing further deformation. These funds are used even in the agricultural industry, as they help protect greenhouses from freezing in the cold season.

to contents ↑Application technology

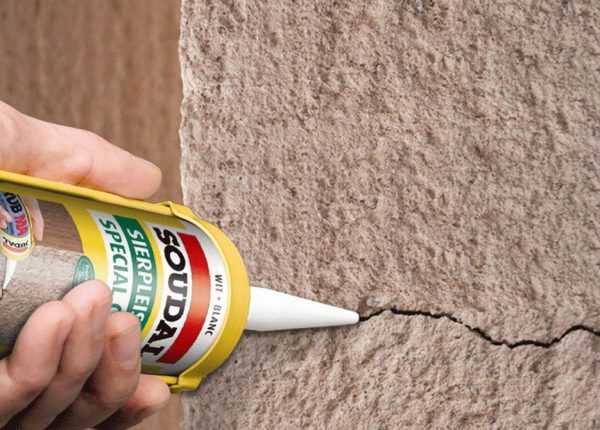

As for the method of use, it is very simple and known to everyone who at least once worked with sealants and knows their features. For this, a special gun is used (mechanical, pneumatic, electric, and so on).

The sealant must be squeezed out evenly, making sure that the seam is not very thin and not too thick. To fill the gap, it is necessary to place the nozzle nozzle in its cavity and then squeeze out the sealant, conducting along the entire length of the hole.

You need to work with these compounds without delay, since the polymerization of some of them occurs quite quickly. It is not recommended to correct the seam with your hands, since the sealant will adhere to the skin, and it is quite difficult to remove it.

to contents ↑Consumption

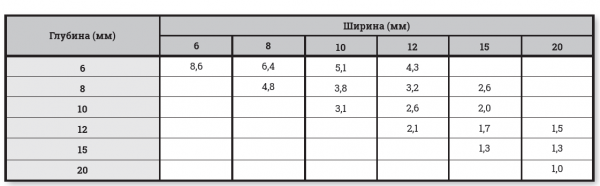

Now let's talk about how much sealant will be required to carry out this or that work. About 6 mm of funds are required per meter of seam, but keep in mind that this is an average indicator. Actual consumption depends on a number of factors:

- depth and width of the gap;

- type of building materials, etc.

If you have to close up a large gap, then in order to save money, it is recommended to use a special silicone cord. First, it is placed in the cavity, and then completely closed with sealant.

If it was required to process a small surface, for example, a window opening, one tube per 300 g would be enough, but the width of the gap between the frame and the wall should also be taken into account.

Tips & Tricks

When working with frost-resistant sealant, use rubber gloves. If you have excess, then you can remove them with ordinary rags, and it is better to do this even before the polymerization of the seam. Old sealant can be removed with a sharp object: clerical or construction knife.

It is not recommended to save on formulations. Cheap sealants from little-known manufacturers, as a rule, either contain all kinds of additives, or do not have sufficient resistance to frost and atmospheric factors.

On sale you can find products not only from foreign, but also from Russian manufacturers. From a practical point of view, there is no difference between them, and the cost of imported products can be much higher. The main thing is to make sure that the sealant is frost and moisture resistant. If you have any difficulties, you can take advantage of the advice of the seller.